Cov chillers muaj lub luag haujlwm tseem ceeb hauv kev txhaj tshuaj molding kev lag luam, muab ntau cov txiaj ntsig tseem ceeb, xws li txhim kho qhov zoo, tiv thaiv deformation, accelerating Demolding thiab Production Efficiency, optimizing cov khoom zoo, thiab txo cov nqi ntau lawm. Peb cov chillers muaj ntau yam qauv tsim nyog rau kev txhaj tshuaj molding xav tau, tso cai rau cov lag luam xaiv qhov zoo tshaj plaws chiller raws li cov khoom siv tshwj xeeb rau kev ua haujlwm zoo thiab ua haujlwm zoo.

Lub luag haujlwm ntawm Industrial Chillers hauv Kev Txhaj Tshuaj Molding Kev Lag Luam

Industrial chillers ua lub luag haujlwm tseem ceeb hauv kev txhaj tshuaj molding kev lag luam, muab ntau yam txiaj ntsig tseem ceeb:

1. Txhim kho Surface Quality:

Cov dej chillers pab cov pwm yas txias, txhim kho qhov smoothness thiab zoo li cov khoom yas. Kev ua kom txias tsis tu ncua txo cov cim saum npoo thiab cov kev ntxhov siab sab hauv, ua rau smoother, polished tiav uas txhim kho tag nrho cov khoom zoo.

2. Tiv thaiv Deformation:

Hauv kev txhaj tshuaj molding, kev ua kom txias zoo tiv thaiv kev shrinkage lossis warping ntawm cov khoom yas thaum lub caij txias. Qhov no pab tswj kom meej qhov ntev thiab ruaj khov, txhim kho cov khoom lag luam tawm los.

3. Accelerating Demolding thiab ntau lawm Efficiency:

Los ntawm kev ua kom cov txheej txheem teeb tsa, cov dej chillers ua kom yooj yim rau cov khoom tso tawm los ntawm cov pwm, ua kom lub voj voog ntau lawm thiab ua kom cov tshuab txhaj tshuaj molding ua tau zoo. Qhov no ua rau cov nqi tsim khoom qis dua.

4. Optimizing khoom zoo:

Hauv kev tsim cov ntim yas thiab ntim cov yeeb yaj kiab, cov chillers muaj peev xwm pab tswj cov duab zoo ib yam thiab cov phab ntsa tuab, thaum tseem txhim kho xim vibrancy thiab molding zoo ntawm zaj duab xis. Qhov no ua rau cov khoom zoo yas uas ua tau raws li cov qauv kev lag luam.

5. Txo cov nqi tsim khoom:

Los ntawm kev txhim kho kev ua tau zoo thiab cov khoom zoo, cov chillers muaj peev xwm pab txo cov khoom pov tseg thiab tag nrho cov nqi tsim khoom. Qhov no muab qhov tseem ceeb ntawm kev lag luam zoo hauv kev txhaj tshuaj molding kev lag luam, cuam tshuam cov txiaj ntsig thiab kev sib tw.

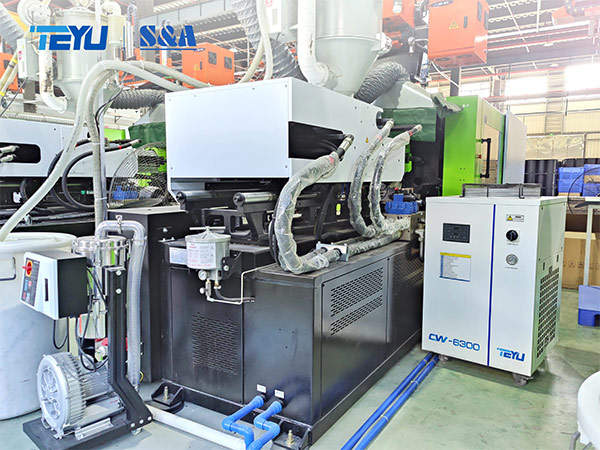

TEYU S&A qhov ntau ntawm cov dej chillers muaj ntau yam qauv tsim nyog rau kev txhaj tshuaj molding xav tau, tso cai rau cov lag luam xaiv qhov zoo tshaj plaws chiller raws li cov khoom siv tshwj xeeb rau kev tsim khoom zoo thiab zoo.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.