Kana chiller chemvura chisina kubatana netambo yechiratidzo, inogona kukonzera kutadza kutonga kwekushisa, kukanganiswa kwealarm system, mitengo yepamusoro yekugadzirisa, uye kuderedzwa kwehunyanzvi. Kuti ugadzirise izvi, tarisa kubatanidza kwehardware, gadzirisa maprotocol ekutaurirana nenzira kwayo, shandisa mabhaudhi echimbichimbi modhi, uye chengetedza kuongorora nguva dzose. Kuvimbika kwechiratidzo kutaurirana kwakakosha pakushanda kwakachengeteka uye kwakagadzikana.

Chii Chinoitika Kana Chiller Isina Kubatana neSiginari Cable uye Magadzirirwo Ayo

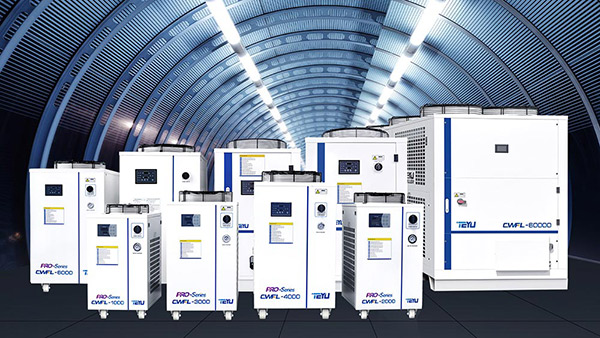

Mukugadzirwa kwemaindasitiri, machiller emvura akakosha ekubatsira midziyo yema lasers uye mamwe masisitimu chaiwo. Nekudaro, kana chiller yemvura isina kunyatsobatanidzwa netambo yechiratidzo, inogona kukonzera nyaya dzakakosha dzekushanda.

Kutanga, kutadza kutonga kwekushisa kunogona kuitika. Pasina kutaurirana kwechiratidzo, iyo chiller yemvura haigone kunyatso kudzora tembiricha, zvichitungamira mukupisa kana kuwandisa kwelaser. Izvi zvinogona kukanganisa kugadzirisa kurongeka uye kunyange kukuvadza core components. Chechipiri, alarm uye interlock mabasa akaremara. Zviratidzo zveyambiro yakakosha hazvigone kutapurirana, zvichiita kuti michina irambe ichishanda pasi pemamiriro asina kujairika uye kuwedzera njodzi yekukuvara kwakanyanya. Chechitatu, kushaikwa kwekudzora kure uye kutarisa kunoda kuongororwa kwemanyore pa-saiti, kuwedzera zvakanyanya mari yekugadzirisa. Chekupedzisira, kushanda nesimba kwesimba uye kugadzikana kwehurongwa kunodzikira, sezvo chiller chemvura chinogona kuramba chichimhanya nesimba guru, zvichikonzera kushandiswa kwesimba kwakanyanya uye hupenyu hupfupi hwesevhisi.

Kuti ugadzirise idzi nyaya dzechiller , matanho anotevera anokurudzirwa:

1. Hardware Inspection

- Tarisa kuti tambo yechiratidzo (kazhinji RS485, CAN, kana Modbus) yakabatana zvakachengeteka kumativi ese maviri (chiller uye laser / PLC).

-Ongorora mapini ekubatanidza oxidation kana kukuvara.

-Shandisa multimeter kuti uone kuenderera kwetambo. Tsiva tambo neyakavharidzirwa yakamonyoroka peya kana zvichidikanwa.

- Ita shuwa kuti maprotocol ekutaurirana, ma baud mareti, uye kero dzemudziyo dzinoenderana pakati pemvura chiller nelaser.

2. Software Configuration

-Gadzirisa marongero ekutaurirana pane mvura chiller control panel kana yepamusoro-level software, kusanganisira protocol mhando, kero yevaranda, uye data furemu fomati.

-Simbisa kuti tembiricha mhinduro, kutanga/kumisa zvidzoreso, uye mamwe masaini mapoinzi akanyatso mepu mukati mePLC/DCS system.

-Shandisa maturusi ekugadzirisa akadai seModbus Poll kuti uedze mhinduro yekuverenga/kunyora yemvura.

3. Emergency Measures

- Chinja chiller yemvura kune yemuno manyorero modhi kana kutaurirana kwarasika.

-Isa yakazvimirira maalarm masisitimu se backup kuchengetedza matanho.

4. Kuchengetedza Kwenguva Yakareba

- Ita nguva dzose chiratidzo chekuongorora tambo uye bvunzo dzekutaurirana.

- Gadziridza firmware sezvinodiwa.

- Dzidzisa vashandi vekugadzirisa kubata kutaurirana uye kugadzirisa dambudziko.

Iyo tambo yechiratidzo inoita se "nervous system" yehungwaru kutaurirana pakati pemvura chiller uye laser system. Kuvimbika kwayo kunokanganisa zvakananga kuchengetedza kwekushanda uye kugadzikana kwemaitiro. Nekuongorora zvine hungwaru kubatanidzwa kwehardware, kumisa maprotocol ekutaurirana nemazvo, uye nekumisikidza redundancy mudhizaini yehurongwa, mabhizinesi anogona kunyatso kudzikisa njodzi yekukanganiswa kwekutaurirana uye kuona kuenderera, kushanda kwakadzikama.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.