Haeba mochini o futhumatsang metsi o sa hokahane le thapo ea lets'oao, o ka baka ho hloleha ha taolo ea mocheso, tšitiso ea sistimi ea alamo, litšenyehelo tse phahameng tsa tlhokomelo, le ts'ebetso e fokotsehileng. Ho rarolla sena, hlahloba likhokahano tsa Hardware, lokisa liprothokholo tsa puisano ka nepo, sebelisa mekhoa ea ho boloka maemo a tšohanyetso, 'me u boloke tlhahlobo ea kamehla. Puisano ea matšoao e tšepahalang e bohlokoa bakeng sa ts'ebetso e bolokehileng le e tsitsitseng.

Ho Etsahala'ng Haeba Chiller e sa Hokahane le Cable ea Signal le Mokhoa oa ho e Rarolla

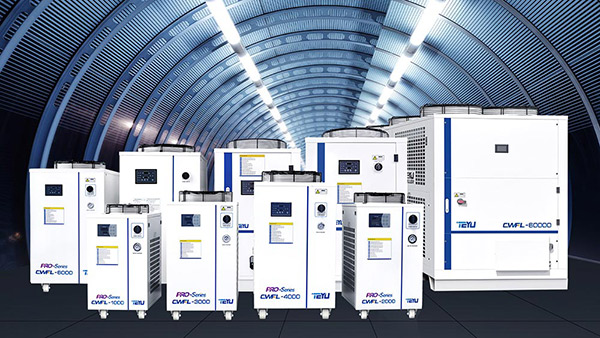

Tlhahisong ea indasteri, li-chillers tsa metsi ke lisebelisoa tsa bohlokoa tse thusang bakeng sa li-lasers le lits'ebetso tse ling tse nepahetseng. Leha ho le joalo, haeba chiller ea metsi e sa hokahane hantle le thapo ea matšoao, e ka baka mathata a bohlokoa a ts'ebetso.

Ntlha ea pele, ho hlōleha ho laola mocheso ho ka 'na ha etsahala. Ntle le puisano ea mats'oao, mochini oa chiller oa metsi o ke ke oa laola mocheso ka nepo, o lebisang ho cheseha kapa ho futhumatsa ha laser. Sena se ka senya ts'ebetso e nepahetseng esita le ho senya likarolo tsa mantlha. Ea bobeli, lits'ebetso tsa alamo le li-interlock li koetsoe. Matshwao a temoso a bohlokwa a ke ke a fetiswa, a etsa hore thepa e tswele pele ho sebetsa tlasa maemo a sa tlwaelehang le ho eketsa kotsi ya tshenyo e kgolo. Ntlha ea boraro, ho haella ha taolo le ho beha leihlo ho hloka hore motho a hlahlojoe ka matsoho sebakeng sa marang-rang, ho eketsa litšenyehelo tsa tlhokomelo haholo. Qetellong, matla a matla le botsitso ba sistimi e fokotseha, kaha mochini o futhumatsang metsi o ka 'na oa sebetsa ka nako e telele ka matla a phahameng, e leng se bakang tšebeliso e phahameng ea matla le bophelo bo khutsufalitsoeng ba ts'ebeletso.

Ho rarolla bothata bona, mehato e latelang e khothaletsoa:

1. Tlhahlobo ea Hardware

- Lekola hore thapo ea lets'oao (hangata RS485, CAN, kapa Modbus) e hoketsoe ka mokhoa o sireletsehileng lipheletsong ka bobeli (chiller le laser/PLC).

- Lekola likhokahano bakeng sa oxidation kapa tšenyo.

- Sebelisa multimeter ho netefatsa ho tsoela pele ha cable. Kenya thapo sebaka ka para e sothehileng e sirelelitsoeng ha ho hlokahala.

- Netefatsa hore liprothokholo tsa puisano, litefiso tsa baud, le liaterese tsa sesebelisoa li lumellana lipakeng tsa mochini o futhumatsang metsi le laser.

2. Sebopeho sa Software

- Hlophisa litlhophiso tsa puisano holim'a phanele ea taolo ea chiller ea metsi kapa software ea boemo bo holimo, ho kenyeletsoa mofuta oa protocol, aterese ea lekhoba, le sebopeho sa foreimi ea data.

- Netefatsa hore maikutlo a mocheso, taolo ea ho qala/e emisa, le lintlha tse ling tsa matšoao li entsoe 'mapa ka nepo ka har'a sistimi ea PLC/DCS.

- Sebelisa lisebelisoa tsa ho lokisa liphoso tse kang Modbus Poll ho lekola karabo ea sebatli sa metsi.

3. Mehato ea Tšohanyetso

- Fetola chiller ea metsi ho mokhoa oa matsoho oa lehae haeba puisano e lahlehile.

- Kenya lisebelisoa tse ikemetseng tsa alamo e le mehato ea polokeho ea bekapo.

4. Tlhokomelo ea Nako e Telele

- Etsa tlhahlobo ea kamehla ea li-cable le liteko tsa puisano.

- Ntlafatsa firmware ha ho hlokahala.

- Koetlisa basebetsi ba tlhokomelo ho sebetsana le puisano le ho rarolla mathata a sistimi.

Mohala oa lets'oao o sebetsa joalo ka "tsamaiso ea methapo" bakeng sa puisano e bohlale lipakeng tsa mochini o futhumatsang metsi le sistimi ea laser. Ho tšepahala ha eona ho ama ka ho toba ts'ireletso ea ts'ebetso le botsitso ba ts'ebetso. Ka ho lekola likhokahano tsa Hardware ka mokhoa o hlophisitsoeng, ho hlophisa liprothokholo tsa puisano ka nepo, le ho theha bofokoli molemong oa moralo oa sistimi, likhoebo li ka fokotsa kotsi ea litšitiso tsa puisano le ho netefatsa ts'ebetso e tsoelang pele, e tsitsitseng.

Re mona bakeng sa hau ha o re hloka.

Ka kopo tlatsa foromo ho ikopanya le rona, 'me re tla thabela ho u thusa.