Umatshini wokusika i-laser sisixhobo esisebenzayo nesichanekileyo sokusika esebenzisa iteknoloji ye-laser ukukhupha ngokukhawuleza izinto ezinobuninzi bamandla. Ezona ndawo ziphambili zokusetyenziswa zibandakanya ishishini lombane, ishishini le-semiconductor, ishishini lamandla elanga, ishishini le-optoelectronics, kunye neshishini lezixhobo zonyango. I-laser chiller igcina inkqubo ye-laser dicing ngaphakathi koluhlu lobushushu obufanelekileyo, ukuqinisekisa ukuchaneka, kunye nozinzo, kunye nokwandisa ngokufanelekileyo ubomi bomatshini wokudayela we-laser, osisixhobo sokupholisa esibalulekileyo koomatshini be-laser dicing.

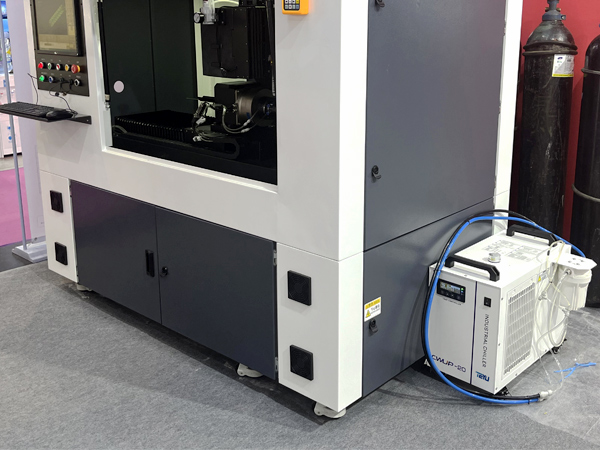

Usetyenziso lweLaser Dicing Machine kunye noBumbeko lweLaser Chiller

Umatshini wokusika i-laser sisixhobo esisebenzayo nesichanekileyo sokusika esebenzisa iteknoloji ye-laser ukukhupha ngokukhawuleza izinto ezinobuninzi bamandla. Oku kubangela ukufudumeza kwangoko kunye nokwandiswa kwezinto, ukudala uxinzelelo lwe-thermal kunye nokuvumela ukusika ngokuchanekileyo. Iqhayisa ngokuchaneka okuphezulu kokusika, ukusika okungadibanisiyo, ukungabikho koxinzelelo lomatshini, kunye nokusikwa okungenamthungo, phakathi kwezinye iingenelo ezibalulekileyo, kwaye ke ngoko ifumana ukusetyenziswa okubanzi kwiinkalo ezahlukeneyo.

IiNdawo ezininzi zeSicelo eziPhambili zoomatshini bokwenza iiLaser Dicing ziquka:

1. Ishishini le-Electronics

Itekhnoloji ye-laser dicing idlala indima ebalulekileyo ekuveliseni iisekethe ezidibeneyo. Inika iingenelo ezifana nobubanzi bomgca ocolekileyo, ukuchaneka okuphezulu (ububanzi bomgca we-15-25μm, ubunzulu be-groove ye-5-200μm), kunye nesantya sokucubungula ngokukhawuleza (ukuya kwi-200mm / s), ukufikelela kwizinga lesivuno ngaphezu kwe-99.5%.

2. Ishishini leSemiconductor

Oomatshini be-Laser dicing basetyenziselwa ukusika iisekethe ezidibeneyo ze-semiconductor, kubandakanywa ukusika kunye nokudaywa kwee-wafers ze-diode enye kunye namacala amabini, i-wafers elawulwa yi-silicon enye kunye namacala amabini, i-gallium arsenide, i-gallium nitride, kunye ne-IC wafer slicing.

3. Ishishini leSolar Energy

Ngenxa yempembelelo encinci ye-thermal kunye nokuchaneka okuphezulu, i-laser dicing isetyenziswa ngokubanzi kwimboni ye-photovoltaic yokusika iipaneli zeeseli zelanga kunye ne-silicon wafers.

4. Ishishini le-Optoelectronics

Oomatshini be-Laser dicing baqeshwe ekusikeni iglasi yamehlo, iifiber zamehlo, kunye nezinye izixhobo ze-optoelectronic, ukuqinisekisa ukuchaneka kokusika kunye nomgangatho.

5. Ishishini leZixhobo zoNyango

Oomatshini beLaser dicing basetyenziselwa ukusika isinyithi, iiplastiki, kunye nezinye izinto kwizixhobo zonyango, ukuhlangabezana nokuchaneka kunye neemfuno zomgangatho wezixhobo zonyango.

Uqwalaselo lweLaser Chiller yeeMishini zokuDiyiza iiLaser

Ngexesha lenkqubo ye-laser dicing, ubushushu obuninzi buyenziwa. Obu bushushu bunokuba neziphumo ezibi kwinkqubo yokudayela kwaye bunokonakalisa i-laser ngokwayo. I -laser chiller igcina inkqubo ye-laser dicing ngaphakathi koluhlu olufanelekileyo lobushushu, ukuqinisekisa ukuchaneka, kunye nokuzinza, kunye nokwandisa ngokufanelekileyo ubomi bomatshini wokudayela we-laser. Sisixhobo sokupholisa esibalulekileyo koomatshini bokudiza ngelaser.

I-TEYU S&A i-laser chillers igubungela amandla okupholisa ukusuka kwi-600W ukuya kwi-42000W, inika ulawulo oluchanekileyo lolawulo lobushushu ukuya kuthi ga kwi-±0.1℃. Bangakwazi ukuhlangabezana ngokugqibeleleyo neemfuno zokupholisa koomatshini bokudiza ngelaser abakhoyo kwiimarike. Ngeminyaka engama-21 yamava kwimveliso ye-chiller, i-TEYU S&A i-Chiller Manufacturer inokuthunyelwa ngonyaka okungaphezulu kwe-120,000 yeeyunithi zokupholisa amanzi . I-laser chiller nganye ivavanywa ngokuqatha kwaye iza newaranti yeminyaka emi-2. Zive ukhululekile ukufikelela ngoku sales@teyuchiller.com ukukhetha esona sisombululo sokupholisa kumatshini wakho wokudayela welaser.

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.