Apabila memilih penyejuk air, kapasiti penyejukan adalah penting tetapi bukan penentu tunggal. Prestasi optimum bergantung pada pemadanan kapasiti penyejuk dengan laser khusus dan keadaan persekitaran, ciri laser dan beban haba. Ia disyorkan penyejuk air dengan kapasiti penyejukan 10-20% lebih untuk kecekapan dan kebolehpercayaan yang optimum.

Bagaimana untuk Menilai Keperluan Penyejukan dengan Tepat untuk Peralatan Laser?

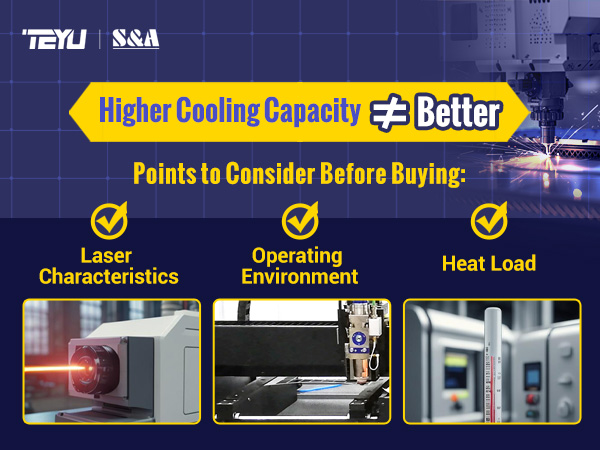

Adakah kapasiti penyejukan yang lebih tinggi sentiasa lebih baik?

Tidak, mencari padanan yang betul adalah kuncinya. Kapasiti penyejukan yang terlalu besar tidak semestinya bermanfaat dan boleh membawa kepada beberapa isu. Pertama, ia meningkatkan penggunaan tenaga dan meningkatkan kos operasi. Kedua, ia menyebabkan permulaan dan berhenti yang kerap pada beban rendah, yang membawa kepada peningkatan haus pada komponen penting seperti pemampat, akhirnya memendekkan jangka hayat peralatan. Selain itu, ia boleh menjadikan kawalan sistem mencabar, mengakibatkan turun naik suhu yang menjejaskan ketepatan pemprosesan laser.

Cara menilai dengan tepat keperluan penyejukan untuk peralatan laser sebelum membeli penyejuk air ? Anda perlu mempertimbangkan:

1. Ciri Laser: Di luar jenis dan kuasa laser, adalah penting untuk mempertimbangkan parameter seperti panjang gelombang dan kualiti pancaran. Laser dengan panjang gelombang dan mod operasi yang berbeza (berterusan, berdenyut, dsb.) menghasilkan jumlah haba yang berbeza-beza semasa penghantaran rasuk. Untuk memenuhi keperluan penyejukan unik pelbagai jenis laser (seperti laser gentian, laser CO2, laser UV, laser ultrafast...), TEYU Water Chiller Maker membekalkan rangkaian penyejuk air yang komprehensif, seperti penyejuk laser gentian siri CWFL , penyejuk laser CO2 siri CW , penyejuk lekap pada rak siri RMFL , siri ultra precision CWUP ±0℃

2. Persekitaran Operasi: Suhu ambien, kelembapan dan keadaan pengudaraan memberi kesan kepada pelesapan haba laser. Dalam persekitaran yang panas dan lembap, penyejuk air perlu menyediakan kapasiti penyejukan yang lebih besar.

3. Beban Haba: Dengan mengira jumlah beban haba laser, termasuk haba yang dijana oleh laser, komponen optik, dll., kapasiti penyejukan yang diperlukan boleh ditentukan.

Sebagai peraturan umum, memilih penyejuk air dengan10-20% lebih banyak kapasiti penyejukan daripada nilai yang dikira adalah pilihan yang bijak, memastikan peralatan laser mengekalkan suhu yang stabil semasa operasi yang berpanjangan. TEYU Water Chiller Maker, dengan pengalaman selama 22 tahun dalam penyejukan laser, boleh menyediakan penyelesaian kawalan suhu yang disesuaikan berdasarkan keperluan penyejukan khusus anda. Sila hubungi kami melaluisales@teyuchiller.com .

Kami ada untuk anda apabila anda memerlukan kami.

Sila lengkapkan borang untuk menghubungi kami, dan kami berbesar hati untuk membantu anda.