Kuwedzera hupenyu hwemalaser welding michina inoda kutariswa kune akasiyana zvinhu senge maitiro ekushanda, mamiriro ekugadzirisa, uye nharaunda yekushanda. Kugadzira yakakodzera kutonhora sisitimu zvakare imwe yematanho akakosha ekuwedzera hupenyu hwayo. TEYU laser welding chillers, ine yakakwirira-tembiricha yekudzora kurongeka, inopa inoenderera uye yakagadzikana tembiricha yekudzora kwelaser welding michina.

Nzira yekunyatsowedzera Hupenyu hweLaser Welding Machines

Laser welding michina, seyepamusoro welding midziyo, vakawana yakapararira kunyorera mumaindasitiri akasiyana. Nekudaro, iwe unoziva nzira yekunyatso wedzera hupenyu hwea laser welding muchina? Ngatikurukurei pamwe chete:

1. Hupenyu hweLaser Welding Machines

Hupenyu hwemashini ekuisa laser welding anosiyana zvichienderana nerudzi, modhi, nharaunda yekushandisa, uye mamiriro ekugadzirisa. Kazhinji, hupenyu hwemalaser welding michina ndeye makore masere kusvika gumi. Nekudaro, kushandiswa zvisina kunaka kana kushaikwa kwekugadzirisa panguva kunogona kupfupisa hupenyu hwechigadzirwa.

2. Nzira Yokuwedzera Upenyu hweLaser Welding Machines

a. Mashandiro Akarurama

Maitiro ekushanda akakodzera akakosha kune hupenyu hwemashini emagetsi welaser welding. Panguva yekushandiswa, kuchengetedza yakagadzika welding kumhanya uye kushandisa akakodzera mafirita zvinhu uchidzivirira zvakanyanya kuzungunuka uye nekukasira kumira kwakakosha. Pamusoro pezvo, kucherechedza mhando yeweld seams uye kugadzirisa welding paramita nekukurumidza kunovimbisa laser welding mhando.

b. Kugara Kuongorora uye Kuchengetedza

Kugara uchiongorora uye kugadzirisa ndizvo kiyi yekuwedzera hupenyu hwemalaser welding michina. Panguva yekuongorora, kutarisa wiring yemidziyo, plugs, switch, nezvimwewo, zvakakosha kuti uve nechokwadi chekuchengetedzwa kwemagetsi. Panguva imwe chete, kuongorora zvinhu zvakaita semusoro welaser, lenses, uye kupisa dissipation system yeguruva kana tsvina uye nekukasira kuchenesa kana kutsiva nhengo dzisina njodzi kwakakosha. Uyezve, kugara uchitarisa pamatanho emidziyo uye zviratidzo zvekushanda zvinoona kuti muchina uri mukushanda kwakanaka.

c. Yakanyanya Kushanda Nzvimbo

Nzvimbo yekushanda inoshanda yakakosha kune hupenyu hwemachina welding laser. Kuchengetedza mhepo yakanaka, kudzivirira kunyorova uye kutonhora kwakanyanya kudzivirira kukuvadzwa kwemidziyo, uye kurega kushandisa muchina munzvimbo dzine guruva kudzivirira kusakara uye kukanganisa muzvikamu zvakakosha kufunga.

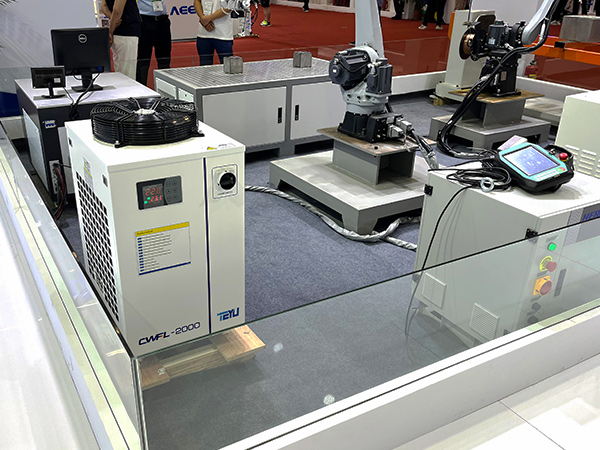

d. Yakakwana Kutonhodza System

Munguva ye laser welding, iyo midziyo inogadzira yakakura yakawanda yekupisa. Kana kupisa uku kukasanyatsodzorwa uye kubviswa, zvinogona kutungamira mukupisa uye kupfupisa hupenyu hwemuchina.

Kugadzirisa yakakodzera kutonhora sisitimu ndechimwe chezvinhu zvakakosha mukuwedzera hupenyu hwemalaser welding michina. Panguva yekushandiswa, kutarisisa kunofanirwa kupihwa kune kushanda kweiyo inotonhora sisitimu, uye kushanda kwakakodzera uye kugadzirisa kunofanirwa kuitwa zvinoenderana nemirairo yakakodzera.

Muchidimbu, kuwedzera hupenyu hwemalaser welding muchina kunoda kutarisisa zvinhu zvakasiyana senge maitiro ekushanda, mamiriro ekugadzirisa, uye nharaunda yekushanda. Kugadzirisa yakakodzera kutonhora sisitimu zvakare imwe yematanho akakosha ekuwedzera hupenyu hwayo.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.