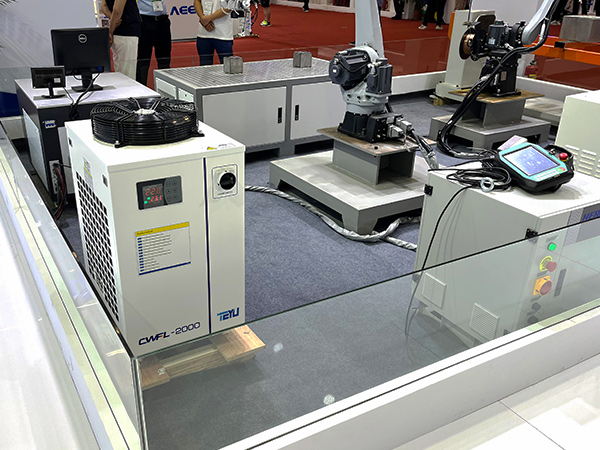

Ho eketsa nako ea bophelo ea mechini ea welding ea laser ho hloka ho ela hloko lintlha tse fapaneng joalo ka mekhoa ea ts'ebetso, maemo a tlhokomelo le tikoloho ea ho sebetsa. Ho hlophisa sistimi e nepahetseng ea ho pholisa hape ke e 'ngoe ea mehato ea bohlokoa bakeng sa ho lelefatsa bophelo ba eona. Li-chiller tsa TEYU laser welding, tse nang le taolo e nepahetseng ea mocheso o phahameng, li fana ka taolo e tsoelang pele le e tsitsitseng ea mocheso bakeng sa mechini ea welding ea laser.

Mokhoa oa ho Eketsa Nako ea Bophelo ea Mechini ea Welding ea Laser ka Katleho

Mechini ea welding ea laser, joalo ka lisebelisoa tse tsoetseng pele tsa tjheseletsa, e fumane lits'ebetso tse atileng liindastering tse fapaneng. Leha ho le joalo, na ua tseba ho lelefatsa bophelo ba mochini oa welding oa laser? Ha re e buisaneng hammoho:

1. Nako ea bophelo ea Mechini ea Welding ea Laser

Nako ea bophelo ea mechini ea welding ea laser e fapana ho latela mofuta, mohlala, tikoloho ea ts'ebeliso le maemo a tlhokomelo. Ka kakaretso, nako ea bophelo ea mechini ea welding ea laser e ka ba lilemo tse 8 ho isa ho tse 10. Leha ho le joalo, tšebeliso e fosahetseng kapa ho se hlokomeloe ka nako ho ka khutsufatsa nako ea bophelo ea sesebelisoa.

2. Mokhoa oa ho Eketsa Nako ea Bophelo ea Mechini ea Welding ea Laser

a. Mekhoa e Nepahetseng ea Ts'ebetso

Mekhoa e nepahetseng ea ts'ebetso e bohlokoa bakeng sa nako ea bophelo ea mochini oa welding oa laser. Nakong ea ts'ebeliso, ho bohlokoa ho boloka lebelo le tsitsitseng la welding le ho sebelisa lisebelisoa tse loketseng tsa li-filler ha o ntse o qoba ho thekesela ho feteletseng le ho emisa ka tšohanyetso ho bohlokoa. Ntle le moo, ho shebella boleng ba seams oa weld le ho lokisa liparamente tsa welding hang-hang ho netefatsa boleng ba welding ea laser.

b. Tlhahlobo le Tlhokomelo ea Kamehla

Tlhahlobo le tlhokomelo ea kamehla ke senotlolo sa ho lelefatsa nako ea bophelo ea mechini ea welding ea laser. Nakong ea tlhahlobo, ho hlahloba lisebelisoa tsa lisebelisoa, li-plug, li-switches, joalo-joalo, hoa hlokahala ho netefatsa tšireletso ea motlakase. Ka nako e ts'oanang, ho hlahloba likarolo tse kang hlooho ea laser, lilense, le tsamaiso ea ho qhala mocheso bakeng sa lerōle kapa litšila le ho hloekisa hang-hang kapa ho nkela likarolo tse tlokotsing ho bohlokoa. Ho feta moo, ho hlahloba khafetsa lisebelisoa tsa lisebelisoa le matšoao a ts'ebetso ho netefatsa hore mochini o sebetsa hantle.

c. Tikoloho e Ntle ea Mosebetsi

Tikoloho e loketseng ea ho sebetsa e bohlokoa bakeng sa nako ea bophelo ea mochini oa welding oa laser. Ho boloka moea o motle, ho qoba maemo a mongobo le a phahameng a mocheso ho thibela tšenyo ea thepa, le ho qoba ho sebelisa mochine libakeng tse nang le lerōle ho thibela ho roala le liphoso likarolong ke lintlha tsa bohlokoa.

d. Mokhoa o lekaneng oa ho Pholisa

Nakong ea welding laser, thepa e hlahisa mocheso o mongata. Haeba mocheso ona o sa laoloe ka katleho le ho qhaloa, o ka lebisa ho futhumala ho feteletseng le ho khutsufatsa bophelo ba mochine.

Ho lokisa mokhoa o loketseng oa ho pholisa ke e 'ngoe ea lintlha tsa bohlokoa ho lelefatsa nako ea bophelo ea mochini oa welding oa laser. Nakong ea ts'ebeliso, tlhokomelo e lokela ho lebisoa ts'ebetsong ea sistimi ea ho pholisa, 'me ts'ebetso e nepahetseng le tlhokomelo e lokela ho etsoa ho latela melaoana e amehang.

Ka kakaretso, ho lelefatsa nako ea bophelo ea mechini ea welding ea laser ho hloka ho ela hloko lintlha tse fapaneng joalo ka mekhoa ea ts'ebetso, maemo a tlhokomelo le tikoloho ea ho sebetsa. Ho hlophisa sistimi e nepahetseng ea ho pholisa hape ke e 'ngoe ea mehato ea bohlokoa bakeng sa ho lelefatsa bophelo ba eona.

Re mona bakeng sa hau ha o re hloka.

Ka kopo tlatsa foromo ho ikopanya le rona, 'me re tla thabela ho u thusa.