Ha alamo ea phallo ea metsi e hlaha ho pholileng ea metsi ea liindasteri e pholileng mochini o kobehang oa CNC, sesosa e ka ba phala kapa pompo ea metsi. Joale a re hlahlobeng ka tsela e latelang:

1.Pipe e ka ntle e koetsoe. Tabeng ena, etsa bonnete ba hore e hlakotsoe;2.Pipe e ka hare e koetsoe. Tabeng ena, e hlatsoe ka metsi a hloekileng ebe u sebelisa sethunya sa moea ho e hlakola;

3.Ho na le ntho e khomaretsoeng ka har'a pompo ea metsi. Tabeng ena, hloekisa pompo ea metsi.

4.Rotor ea pompo ea metsi e senyeha, e lebisang botsofaling ba pompo ea metsi. Tabeng ena, fetola pompo eohle ea metsi.

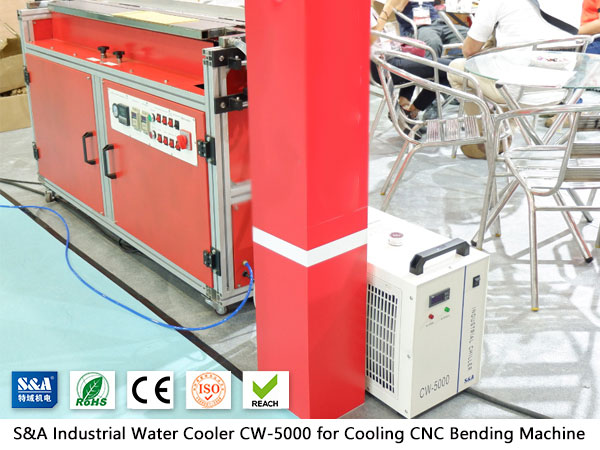

Kamora nts'etsopele ea lilemo tse 17, re theha sistimi e tiileng ea boleng ba sehlahisoa mme re fana ka ts'ebeletso e thehiloeng hantle kamora thekiso. Re fana ka mefuta e fetang 90 e tloaelehileng ea chiller ea metsi le mefuta e 120 ea metsi bakeng sa ho ikhethela. Ka matla a ho pholisa ho tloha ho 0.6KW ho isa ho 30KW, li-chiller tsa rona tsa metsi li sebetsa mehloling e fapaneng ea laser e pholileng, metjhini e lokisang laser, mechini ea CNC, lisebelisoa tsa bongaka, lisebelisoa tsa laboratori joalo-joalo.