Ukwandisa ixesha lokuphila koomatshini bokuwelda i-laser kufuna ingqalelo kwizinto ezahlukeneyo ezifana neenkqubo zokusebenza, iimeko zokugcina, kunye nemeko yokusebenza. Ukuqwalasela isixokelelwano sokupholisa esifanelekileyo ngomnye wamanyathelo abalulekileyo okwandisa ubomi bayo. I-TEYU laser welding chillers, ngokuchaneka kokulawula ubushushu obuphezulu, ibonelela ngokuqhubekayo kunye nolawulo lobushushu obuzinzileyo kumatshini we-laser welding.

Indlela yokwandisa ixesha loBomi lweLaser Welding Machines

Oomatshini bokuwelda beLaser, njengezixhobo zokuwelda eziphambili, bafumene izicelo ezixhaphakileyo kumashishini ahlukeneyo. Nangona kunjalo, ngaba uyayazi indlela yokwandisa ubomi bomatshini we-laser welding? Masiyixoxe kunye:

1. Ubomi beLaser Welding Machines

Ubomi koomatshini be-laser welding iyahluka ngokuxhomekeke kwi-brand, imodeli, indawo yokusetyenziswa, kunye neemeko zokugcinwa. Ngokubanzi, ubomi boomatshini bokuwelda ngelaser bumalunga ne-8 ukuya kweli-10 iminyaka. Nangona kunjalo, ukusetyenziswa okungafanelekanga okanye ukungabikho kokulungiswa kwangethuba kunokunciphisa ubomi besixhobo.

2. Indlela yokwandisa ubomi beLaser Welding Machines

a. IiNkqubo zokuSebenza ezichanekileyo

Iinkqubo ezifanelekileyo zokusebenza zibalulekile kubomi boomatshini bokuwelda ngelaser. Ngexesha lokusetyenziswa, ukugcina isantya se-welding esizinzileyo kunye nokusetyenziswa kwezixhobo ezifanelekileyo zokuhluza ngelixa uthintela ukujinga okugqithisileyo kunye nokuma ngequbuliso kubalulekile. Ukongeza, ukujonga umgangatho we-weld seams kunye nokulungelelanisa iiparamitha ze-welding ngokukhawuleza kuqinisekisa umgangatho we-laser welding.

b. Ukuhlolwa rhoqo kunye noLondolozo

Ukuhlolwa rhoqo kunye nokugcinwa ngundoqo ekwandiseni ixesha lokuphila koomatshini be-laser welding. Ngexesha lokuhlolwa, ukujonga i-wiring yesixhobo, iiplagi, iiswitshi, njl., kuyimfuneko ukuqinisekisa ukhuseleko lombane. Kwangaxeshanye, ukuvavanya amacandelo afana nentloko ye-laser, iilensi, kunye nenkqubo yokuchitha ubushushu kuthuli okanye ukungcola kunye nokucoca ngokukhawuleza okanye ukutshintsha iindawo ezisesichengeni kubalulekile. Ngapha koko, ukujongwa rhoqo kwiiparamitha zezixhobo kunye nezalathi zokusebenza ziqinisekisa ukuba umatshini ukwimeko entle yokusebenza.

c. Indawo yokuSebenza eNgcono

Indawo yokusebenza efanelekileyo ibalulekile kubomi boomatshini bokuwelda belaser. Ukugcina umoya omhle, ukuphepha iimeko ezimanzi kunye nokushisa okuphezulu ukukhusela umonakalo kwisixhobo, kunye nokuyeka ukusebenzisa umatshini kwiindawo ezinothuli ukukhusela ukunxiba kunye neempazamo kumacandelo yingqwalasela ebalulekileyo.

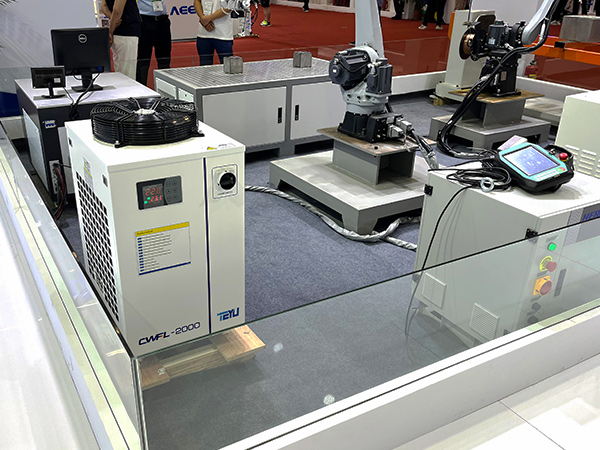

d. Inkqubo yokupholisa eyaneleyo

Ngexesha le-laser welding, izixhobo zivelisa inani elikhulu lobushushu. Ukuba obu bushushu abulawulwa ngokufanelekileyo kwaye buchithwe, bunokukhokelela ekushiseni okugqithisileyo kunye nokunciphisa ubomi bomatshini.

Ukuqwalasela inkqubo yokupholisa efanelekileyo yenye yezinto ezibalulekileyo ekwandiseni ixesha lokuphila koomatshini be-laser welding. Ngexesha lokusetyenziswa, kufuneka kunikwe ingqwalasela ekusebenzeni kwesixokelelwano sokupholisa, kwaye ukusebenza ngokufanelekileyo kunye nokugcinwa kufuneka kuqhutywe ngokwemigaqo efanelekileyo.

Isishwankathelo, ukwandisa ixesha lokuphila koomatshini be-laser welding kufuna ingqalelo kwizinto ezahlukeneyo ezifana neenkqubo zokusebenza, iimeko zokulondoloza, kunye nendawo yokusebenza. Ukuqwalasela isixokelelwano sokupholisa esifanelekileyo ngomnye wamanyathelo abalulekileyo okwandisa ubomi bayo.

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.