Ukwelula isikhathi sokuphila kwemishini yokushisela i-laser kudinga ukunakwa ezicini ezahlukahlukene njengezinqubo zokusebenza, izimo zokunakekela, nendawo yokusebenza. Ukumisa isistimu yokupholisa efanele nakho kungenye yezinyathelo ezibalulekile zokwandisa ubude bayo bempilo. Ama-chiller we-laser welding we-TEYU, anokunemba kokulawula izinga lokushisa eliphezulu, ahlinzeka ngokulawula izinga lokushisa okuqhubekayo nokuzinzile kwemishini yokushisela i-laser.

Indlela Yokunweba Ngokuphumelelayo Isikhathi Sokuphila Semishini Yokushisela I-Laser

Imishini yokushisela i-laser, njengemishini yokushisela ethuthukisiwe, ithole ukusetshenziswa okusakazekile ezimbonini ezahlukahlukene. Kodwa-ke, uyazi ukuthi unganweba kanjani ngempumelelo isikhathi sokuphila somshini wokushisela we-laser? Ake sikuxoxe ndawonye:

1. Isikhathi sokuphila semishini yokushisela i-Laser

Impilo yemishini yokushisela i-laser iyahlukahluka kuye ngohlobo, imodeli, indawo esetshenziswayo, kanye nezimo zokunakekelwa. Ngokuvamile, isikhathi sokuphila semishini yokushisela i-laser cishe siyiminyaka eyi-8 kuye kweyi-10. Kodwa-ke, ukusetshenziswa okungafanele noma ukuntuleka kokunakekelwa okufika ngesikhathi kungase kufinyeze isikhathi sempilo yesisetshenziswa.

2. Indlela Yokwandisa Ukuphila Kwemishini Yokushisela I-Laser

a. Izinqubo Ezilungile Zokusebenza

Izinqubo ezifanele zokusebenza zibalulekile empilweni yemishini yokushisela i-laser. Ngesikhathi sokusetshenziswa, ukugcina isivinini sokushisela esizinzile nokusebenzisa izinto zokugcwalisa ezifanele ngenkathi ugwema ukushwibeka ngokweqile nokuma okungazelelwe kubalulekile. Ukwengeza, ukubheka ikhwalithi ye-weld seams nokulungisa amapharamitha wokushisela kuqinisekisa ikhwalithi yokushisela i-laser.

b. Ukuhlola kanye Nokunakekela Okuvamile

Ukuhlola njalo nokugcinwa kokunakekelwa kuyisihluthulelo sokwandisa isikhathi sokuphila semishini yokushisela i-laser. Ngesikhathi sokuhlolwa, ukuhlola izintambo zemishini, amapulaki, amaswishi, njll., kuyadingeka ukuze kuqinisekiswe ukuphepha kukagesi. Ngesikhathi esifanayo, ukuhlola izingxenye ezifana nekhanda le-laser, amalensi, nesistimu yokukhipha ukushisa yothuli noma ukungcola kanye nokuhlanza ngokushesha noma ukufaka esikhundleni sezingxenye ezisengozini kubalulekile. Ngaphezu kwalokho, ukuhlolwa okuvamile kwemingcele yemishini nezinkomba zokusebenza kuqinisekisa ukuthi umshini usesimweni esihle sokusebenza.

c. Indawo yokusebenza Ekahle

Indawo yokusebenza efanelekile ibalulekile empilweni yemishini yokushisela i-laser. Ukugcina umoya omuhle, ukugwema izimo ezimanzi kanye nezinga lokushisa eliphezulu ukuvimbela ukulimala kwemishini, nokugwema ukusebenzisa umshini ezindaweni ezinothuli ukuvimbela ukuguga namaphutha ezingxenyeni kubalulekile ukucatshangelwa.

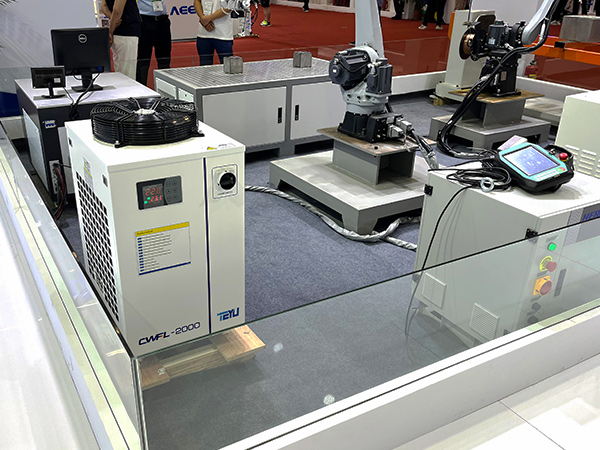

d. Isistimu Yokupholisa Eyanele

Ngesikhathi sokushiswa kwe-laser, imishini ikhiqiza inani elikhulu lokushisa. Uma lokhu kushisa kungalawuleki kahle futhi kuhlakazwe, kungaholela ekushiseni ngokweqile futhi kufinyeze isikhathi sokuphila somshini.

Ukumisa uhlelo olufanele lokupholisa kungenye yezinto ezibalulekile ekwandiseni isikhathi sokuphila semishini yokushisela i-laser. Ngesikhathi sokusetshenziswa, kufanele kuqashelwe ukusebenza kwesistimu yokupholisa, futhi ukusebenza nokugcinwa ngendlela efanele kufanele kwenziwe ngokwemithetho efanele.

Kafushane, ukwelula isikhathi sokuphila kwemishini yokushisela i-laser kudinga ukunakwa ezicini ezahlukahlukene njengezinqubo zokusebenza, izimo zokunakekela, nendawo yokusebenza. Ukumisa isistimu yokupholisa efanele nakho kungenye yezinyathelo ezibalulekile zokwandisa ubude bayo bempilo.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.