Kuyadingeka ukugcina kahle isiqandisi ukuze uqinisekise ukusebenza kahle kokupholisa. Kufanele uhlole amazinga efriji njalo, ukuguga kwemishini, nokusebenza kahle. Ngokuhlola njalo nokugcina isiqandisi, isikhathi sokuphila sama-laser chiller singanwetshwa, kuqinisekiswe ukusebenza kwawo okuzinzile.

Ukugcinwa kwesiqandisi kuma-Laser Chillers

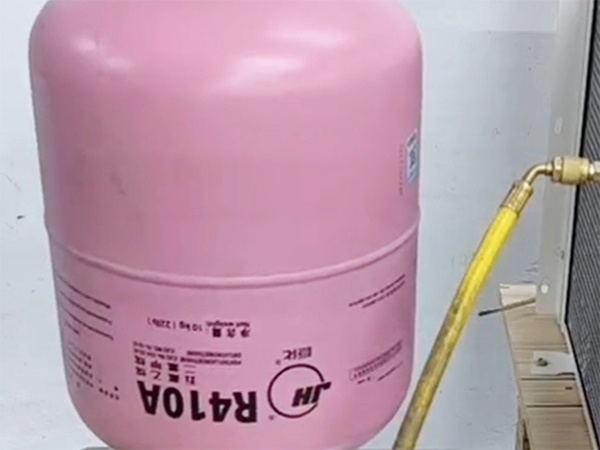

Isiqandisi, esikwaziwa nangokuthi yi-coolant, siyingxenye ebalulekile emjikelezweni wesiqandisi wamayunithi e-laser chiller . Lapho ama-laser chiller e-TEYU ethunyelwa esuka efekthri, akhokhiswa kusengaphambili inani elifanele lesiqandisi ukuze kuqinisekiswe ukusebenza okuvamile nokusebenza kahle kwe-chiller. Kodwa-ke, kuyadingeka futhi ukugcina isiqandisi ngendlela efanele ukuze uqinisekise ukusebenza kahle kokupholisa.

Ukusetshenziswa kwesiqandisi: Ngokuhamba kwesikhathi, isiqandisi singancipha kancane kancane ngenxa yezizathu ezihlukahlukene njengokuvuza, izici zemvelo, noma ukuguga kwemishini. Ngakho-ke, kubalulekile ukuhlola njalo amazinga efriji. Uma izinga lesiqandisi litholakala liphansi, kufanele ligcwaliswe ngokushesha.

Ukuguga kwemishini: Izingxenye zangaphakathi ze-laser chiller, njengamapayipi nama-seal, zingase ziwohloke noma ziguge ngokuhamba kwesikhathi, okuholela ekuvuzeni kwesiqandisi. Ukunakekelwa okuvamile nokuhlolwa kungasiza ekuhlonzeni nasekulungiseni lezi zinkinga ngokushesha, ngaleyo ndlela kugweme ukulahlekelwa okukhulu kwesiqandisi.

Ukusebenza kahle: Izinga eliphansi lesiqandisi noma ukuvuza kungaphazamisa ukusebenza kokupholisa kweziqandisi zamanzi, okuholela ekunciphiseni ukusebenza kahle. Ukuhlola okuvamile nokushintshwa kwesiqandisi kusiza ekugcineni ukusebenza kahle kwe-chiller.

Ngokuhlola njalo nokugcina isiqandisi, isikhathi sokuphila sama-laser chiller singanwetshwa, kuqinisekiswe ukusebenza kwawo okuzinzile. Uma unemibuzo mayelana nokushintshwa kwesiqandisi noma udinga usizo lochwepheshe, sicela ufune isiqondiso kubasebenzi abaqeqeshiwe.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.