Ngemuva kokusetshenziswa isikhathi eside, ama-chiller asezimbonini ajwayele ukuqoqa uthuli nokungcola, kube nomthelela ekusebenzeni kwawo kokukhipha ukushisa nokusebenza kahle. Ngakho-ke, ukuhlanzwa okuvamile kwamayunithi e-industrial chiller kubalulekile. Izindlela eziyinhloko zokuhlanza ama-chillers ezimbonini isihlungi sothuli kanye nokuhlanza i-condenser, ukuhlanza amapayipi ohlelo lwamanzi, kanye nesici sokuhlunga nokuhlanza isikrini sokuhlunga. Ukuhlanza okuvamile kusiza ukugcina isimo sokusebenza esilungile se-industrial chiller futhi kunwebe ngempumelelo impilo yayo.

Izindlela Zokuhlanza Ezivamile kanye Nezokunakekela zamayunithi e-Industrial Chiller

Ngemuva kokusetshenziswa isikhathi eside, ama-chiller asezimbonini ajwayele ukuqoqa uthuli nokungcola, kube nomthelela ekusebenzeni kwawo kokukhipha ukushisa nokusebenza kahle. Ngakho-ke, ukuhlanzwa okuvamile kwamayunithi e-industrial chiller kubalulekile. Ake sihlole izindlela ezimbalwa zokuhlanza ama-chillers asezimbonini:

Isihlungi Sothuli kanye Nokuhlanza I-Condenser:

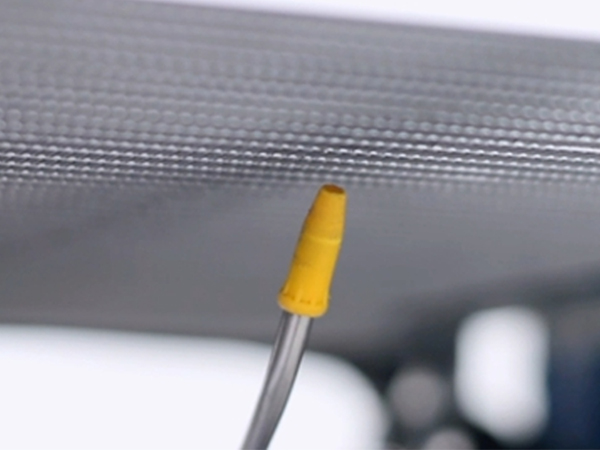

Hlanza ngezikhathi ezithile uthuli nokungcola okungaphezulu kwesihlungi sothuli kanye ne-condenser yezinto ezibandayo zasezimbonini usebenzisa isibhamu somoya.

*Qaphela: Gcina ibanga eliphephile (cishe u-15cm) phakathi kwesibhamu somoya kanye nerediyetha ye-condenser. Isibhamu somoya kufanele sishaye siqonde ku-condenser.

Ukuhlanzwa Kwepayipi Lesistimu Yamanzi:

Kunconywa ukusebenzisa amanzi acwengekile noma amanzi ahlanzekile njengendawo yokupholisa izimboni, ngokushintshwa okujwayelekile ukuze kuncishiswe ukwakheka kwesikali. Uma isikali eseqile sinqwabelana ku-chiller yemboni, kungase kuqalise ama-alamu agelezayo futhi kuthinte ukusebenza kahle kwesibandisi semboni. Ezimweni ezinjalo, ukuhlanza amapayipi amanzi ajikelezayo kuyadingeka. Ungaxuba i-ejenti yokuhlanza namanzi, ucwilise amapayipi kule ngxube isikhathi esithile, bese uhlanza amapayipi ngokuphindaphindiwe ngamanzi ahlanzekile uma isikali sesithambile.

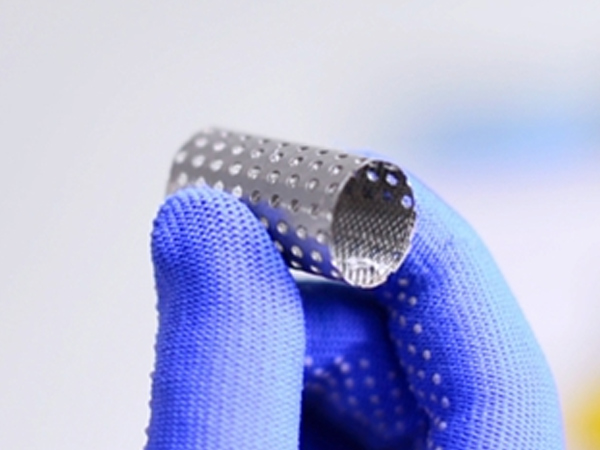

Ukuhlanza Isici Sokuhlunga kanye Nesikrini Sokuhlunga:

Isici sokuhlunga/isikrini sesihlungi siyindawo ejwayeleke kakhulu yokuqoqa ukungcola, futhi sidinga ukuhlanzwa njalo. Uma isici sokuhlunga/isikrini sesihlungi singcole kakhulu, kufanele sishintshwe ukuze kuqinisekiswe ukugeleza kwamanzi okuzinzile ku-chiller yemboni.

Ukuhlanza okuvamile kusiza ukugcina isimo sokusebenza esilungile se-industrial chiller futhi kunwebe ngempumelelo impilo yayo. Sicela uqinisekise ukuthi ugesi uvaliwe ngaphambi kokwenza noma yimiphi imisebenzi yokuhlanza ukuze uqinisekise ukuphepha komuntu siqu kwabaqhubi. Ukuze uthole ulwazi olwengeziwe ngokulungiswa kwamayunithi ezimboni ezipholile , zizwe ukhululekile ukuthumela i-imeyiliservice@teyuchiller.com ukuze uthintane nethimba lesevisi yezobuchwepheshe le-TEYU!

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.