As a user of industrial water chiller system, you might know pretty well that you need to change out the water after using the chiller for a period of time. But do you know why?

Well, changing out water is one of the most important maintenance jobs for industrial water chiller.

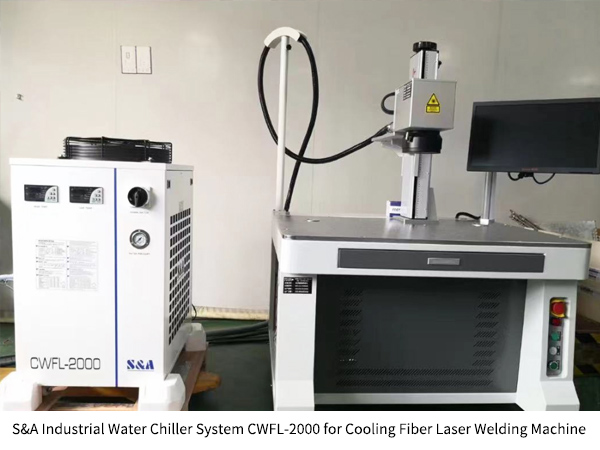

That is because when the laser machine is working, the laser source will generate a vast amount of heat and needs an industrial water cooling chiller to take away the heat. During the water circulation between the chiller and the laser source, there will be some kinds of dust, metal filling and other impurities. If this contaminated water is not replaced by clean circulating water regularly, it is likely that the water channel in the industrial water cooling chiller will become clogged, affecting the normal operation of the chiller.

This kind of clogging will also occur in the water channel inside the laser source, leading to slower water flow and further poor refrigeration performance. Therefore, the laser output and the laser light quality will also be affected and their life span will be shortened.

From the above mentioned analysis, you can see the the water quality is quite important and changing out water regularly is quite necessary. So what kind of water should be used? Well, purified water or clean distilled water or deionised water is also applicable. That is because these kinds of water contain very little ion and impurities, which can reduce the clogging inside the chiller. For the changing water frequency, it is suggested to change it every 3 months. But for dusty environment, it is suggested to change out every 1 month or every half of a month.