In the hot summer, even water chillers begin to face problems such as insufficient heat dissipation, unstable voltage, and frequent high-temperature alarms... Are these troubles caused by the hot weather bothering you? Don't worry, these practical cooling tips can keep your industrial water chiller cool and running stably throughout the summer.

How to Keep Your Water Chiller Cool and Steady Through the Summer?

When summer hits, even water chillers start to "fear the heat"! Inadequate heat dissipation, unstable voltage, frequent high-temperature alarms... Are these hot-weather headaches troubling you? Don't worry—TEYU S&A engineers offer some practical cooling tips to help your industrial chiller stay cool and run steadily all summer long.

1. Optimize the Operating Environment for Chillers

* Place It Properly—Create a "Comfort Zone" for Your Chiller

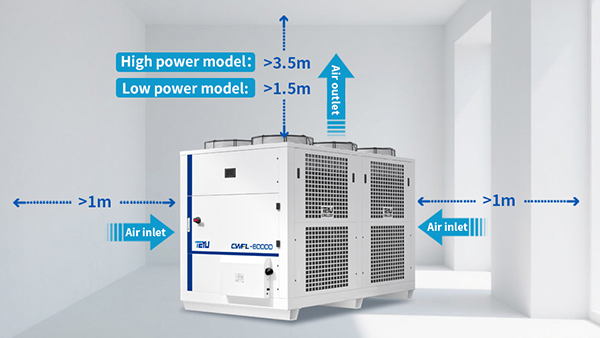

To ensure effective heat dissipation, the chiller should be positioned with enough space around it:

For low-power chiller models: Allow ≥1.5m of clearance above the top air outlet, and maintain ≥1m distance from side air inlets to any obstacles. This ensures smooth airflow circulation.

For high-power chiller models: Increase the top clearance to ≥3.5m while keeping side air inlets ≥1m away to prevent hot air recirculation and efficiency loss.

* Keep Voltage Stable – Prevent Unexpected Shutdowns

Install a voltage stabilizer or use a power source with voltage stabilization, which helps avoid the abnormal chiller operation caused by unstable voltage during summer peak hours. It is recommended that the electric power of the voltage stabilizer be at least 1.5 times greater than that of the chiller.

* Control Ambient Temperature – Boost Cooling Performance

If the operating ambient temperature of the chiller exceeds 40°C, it may trigger a high-temperature alarm and cause the chiller to shut down. To avoid this, keep the ambient temperature between 20°C and 30°C, which is the optimal range.

If the workshop temperature is high and affects the equipment's normal use, consider physical cooling methods such as using water-cooled fans or water curtains to lower the temperature.

2. Perform Regular Chiller Maintenance, Keep the System Efficient Over Time

* Regular Dust Removal

Regularly use an air gun to clean the dust and impurities from the dust filter and condenser surface of the chiller. Accumulated dust can impair heat dissipation, potentially triggering high-temperature alarms. (The higher the chiller power, the more frequently dusting is required.)

Note: When using an air gun, maintain a safe distance of about 10cm from the condenser fins and blow vertically toward the condenser.

* Cooling Water Replacement

Replace the cooling water regularly, ideally every quarter, with distilled or purified water. Also, clean the water tank and pipes to prevent deterioration of water quality, which can affect cooling efficiency and equipment lifespan.

* Change Filter Elements—Let the Chiller "Breathe" Freely

Filter cartridge and screen are prone to accumulating dirt in chillers, so they require regular cleaning. If they are excessively dirty, replace them promptly to ensure stable water flow in the chiller.

For more industrial water chiller maintenance or troubleshooting guides, please stay tuned for updates on our website. If you encounter any after-sales problems, please feel free to contact our customer service team at service@teyuchiller.com.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.