Laser welding le laser soldering ke mekhoa e 'meli e fapaneng e nang le melao-motheo e fapaneng ea ho sebetsa, lisebelisoa tse sebetsang, le lisebelisoa tsa indasteri. Empa tsamaiso ea bona ea ho pholisa "laser chiller" e ka tšoana - TEYU CWFL letoto la fiber laser chiller, taolo e bohlale ea mocheso, pholile e tsitsitseng le e sebetsang hantle, e ka sebelisoa ho pholile ka bobeli mechine ea ho tjheseletsa laser le mechine ea laser soldering.

Phapang Pakeng Tsa Laser Welding & Soldering Le Sistimi ea Bona ea Pholiso

Laser welding le laser soldering ke mekhoa e 'meli e fapaneng e nang le melao-motheo e fapaneng ea ho sebetsa, lisebelisoa tse sebetsang le lisebelisoa tsa indasteri. Empa sistimi ea bona ea ho futhumatsa " laser chiller " e ka tšoana: li-chiller tsa metsi tsa indasteri tsa TEYU li ka sebelisoa ho pholisa mochini oa welding oa laser le oa solder.

Melao-motheo e sebetsang e fapane

Laser soldering e sebelisa matla a phahameng a matla a laser ho fihlela mocheso oa lehae kapa oa micro-regional ho phethela ts'ebetso ea welding. Ka lehlakoreng le leng, laser welding e shebana le taolo e nepahetseng ea kabo ea matla a laser. Le ha ka bobeli li itšetleha ka maballo a laser joalo ka mehloli ea mocheso, li fapana ka tekheniki.

Laser welding ke mofuta o mong oa ts'ebetso ea laser. E sebelisa laser e le mohloli oa mocheso ho khantša pele (kapa lithapo tsa khokahano ea lisebelisoa tse se nang lead), le ho fetisetsa mocheso ho substrate e sebelisa li-solder tse ikhethileng tse kang laser solder paste, terata ea solder, kapa maqephe a solder a entsoeng esale pele. Ha ntlha ea ho qhibiliha ea solder e fihletsoe, e qhibiliha ebe e kolobisa substrate ebe e lebisa ho theha lenonyeletso. Laser welding e sebelisa matla a matla a laser pulses ho futhumatsa libaka tse nyane tsa thepa sebakeng sa heno. Matla a mahlaseli a laser a kenella ka har'a thepa ka ho tsamaisa mocheso, a e qhibilihisa ho etsa letamo le khethehileng le qhibilihisitsoeng.

Lisebelisoa tse sebetsang le masimo a Kopo bakeng sa Soldering ea Laser

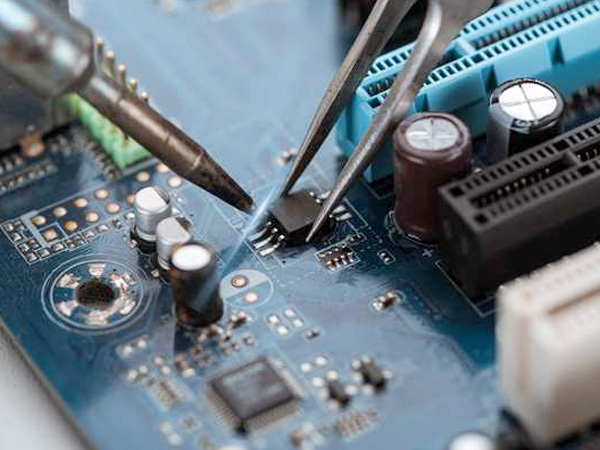

Mechini ea solder ea Laser e khona ho rekisa lisebelisoa tse kang li-plug-ins tse kentsoeng ka morao, likarolo tse sa utloeng mocheso, likarolo tse thata ho solder, li-micro-speakers / motors, SMT post-welding ea li-PCB tse fapaneng, likarolo tsa mohala oa thekeng, jj.

Lisebelisoa tse sebetsang le masimo a Kopo bakeng sa Welding ea Laser

Mochini oa welding oa laser o ka sebelisoa ho cheselletsa litšepe le polasetiki. E sebelisoa haholo mafapheng a fapaneng a kang libeteri, matla a letsatsi, likhokahano tsa mehala ea mohala, likhokahano tsa fiber optical, hlobo, lisebelisoa tsa elektroniki, lisebelisoa tse kopaneng tsa IC, lisebelisoa le limithara, mabenyane a khauta le silevera, lisebelisoa tse nepahetseng, lisebelisoa tsa sefofane, indasteri ea likoloi le indasteri ea motlakase.

Li-Chillers tsa Metsi a Liindasteri bakeng sa Mechini e pholileng ea Laser Soldering le Mechini ea Welding ea Laser

Ha ho tluoa tabeng ea laser soldering le laser welding, taolo e nepahetseng ea mocheso e bohlokoa bakeng sa ts'ebetso e nepahetseng. Kaha li-laser li na le kutloelo-bohloko haholo ho mocheso, taolo e tsitsitseng ea mocheso e ka fella ka ho cheselletsa ho hloekisitsoeng le lihlahisoa tse phahameng.

TEYU Industrial water chiller ke mothusi ea hloahloa oa taolo ea mocheso o etselitsoeng ka ho khetheha lisebelisoa tsa laser soldering le welding. Ka mekhoa e 'meli e ikemetseng ea ho laola mocheso, mokhoa oa ho laola mocheso o phahameng o pholisa hlooho ea laser 'me mokhoa oa ho laola mocheso o tlase o pholisa laser ka boeona. Ho feta moo, laser chiller ena e ka boloka sebaka sa ho kenya. Botsitso ba mocheso oa li-chillers tsa laser bo fihla ho ± 0.1 ℃. Taolo ea eona e nepahetseng ea mocheso e tiisa sehatsetsi se sebetsang hantle nakong ea welding laser le solder processing, kahoo e ntlafatsa ts'ebetso ea ts'ebetso le ho lelefatsa bophelo ba tšebeletso ea lisebelisoa.

Re mona bakeng sa hau ha o re hloka.

Ka kopo tlatsa foromo ho ikopanya le rona, 'me re tla thabela ho u thusa.