Tharollo e Ntle ea ho Pholisa bakeng sa 3000W Fiber Lasers ho SLS SLM Metal 3D Printing Equipment

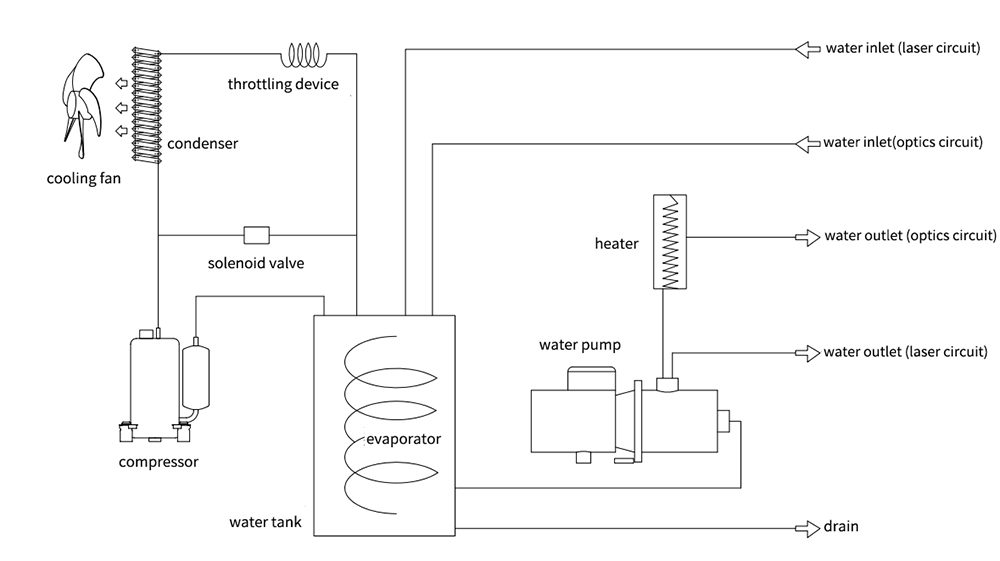

TEYU Industrial Chiller CWFL-3000 ke tharollo e ikhethang ea ho pholisa e etselitsoeng ka ho khetheha mehloli ea laser ea faeba ea 3000W e sebelisoang mahlaleng a khatiso ea tšepe ea 3D joalo ka Selective Laser Sintering (SLS) le Selective Laser Melting (SLM). Moralo oa eona o ikhethang oa kanale ea ho pholisa habeli o lumella ho pholisa ka nako e le 'ngoe ha laser le likarolo tse ling tsa bohlokoa tsamaisong, ho netefatsa ho qhala ha mocheso hantle le khatiso e nang le matla a mangata, ho ntlafatsa ho nepahala ka kakaretso ha likarolo tsa tšepe tse hatisitsoeng.

3D Printer Chiller CWFL-3000 e fana ka taolo e nepahetseng ea mocheso, ho tšoarella ho ikhethang, le ts'ebeliso e ntle ea matla, e leng se etsang hore e be ntle bakeng sa litsamaiso tsa SLS le SLM tsa indasteri. E fana ka pholiso e tsoelang pele le e tšepahalang, e ntlafatsa ts'ebetso le bophelo ba liprinta tsa tšepe tsa 3D ha ka nako e ts'oanang e ntlafatsa ts'ebetso ea tlhahiso le ho fokotsa litšenyehelo tsa ts'ebetso. Ke khetho e phethahetseng bakeng sa basebelisi ba batlang tharollo ea pholiso e nang le bokhoni bo phahameng, e etselitsoeng ts'ebetso ea bona ea khatiso ea tšepe ea 3D.

Mohlala: CWFL-3000

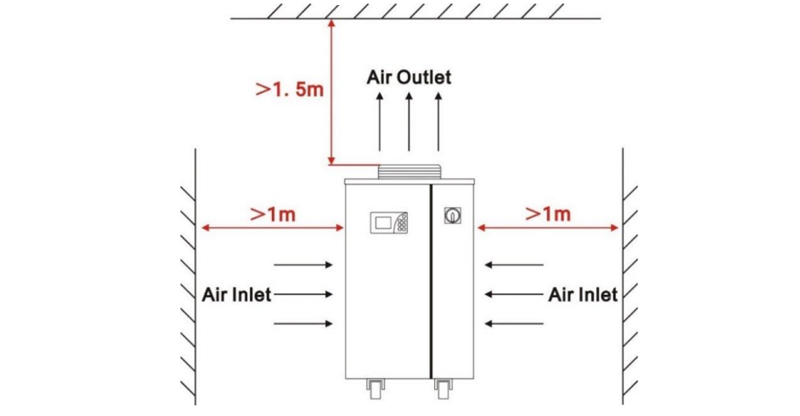

Boholo ba Mochini: 77X55X103cm (LXWXH)

Warranty: lilemo tse 2

Maemo: CE, REACH le RoHS

| Mohlala | CWFL-3000ANPTY | CWFL-3000BNPTY | CWFL-3000ENPTY |

| Palo ea li-volts | AC 1P 220-240V | AC 1P 220-240V | AC 3P 380V |

| Khafetsa | 50Hz | 60Hz | 50Hz |

| Hona joale | 5~33.3A | 3.6~30.9A | 2.1~14A |

Max. tshebediso ya matla | 5.76kW | 6.05kW | 6.08kW |

Matla a heater | 600W+1400W | ||

| Nepahalo | ±0.5℃ | ||

| Mofokotsi | Capillary | ||

| Matla a pompo | 0.75kW | 1kW | 0.75kW |

| Bokhoni ba tanka | 22L | ||

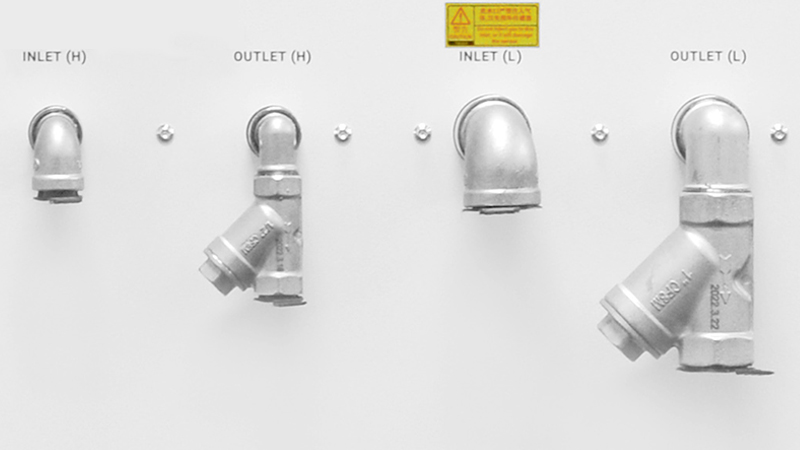

| Ho kena le ho tsoa | Rp1/2”+Rp1” | ||

Max. khatello ea pompo | 5 bar | 5.9 bar | 5 bar |

| Phallo e lekantsoeng | 2L/min+>30L/min | ||

| N.W. | 93Kg | 87Kg | 105Kg |

| G.W. | 109Kg | 103Kg | 121Kg |

| Boemo | 77X55X103cm (LXWXH) | ||

| Boemo ba sephutheloana | 78X65X117cm (LXWXH) | ||

Nako ea ho sebetsa e ka fapana tlas'a maemo a fapaneng a ho sebetsa. Lintlha tse ka holimo ke tsa litšupiso feela. Ka kopo, u ipapisitse le sehlahisoa sa 'nete se rometsoeng.

* Taolo e Nepahetseng ea Mocheso: E boloka pholiso e tsitsitseng le e nepahetseng ho thibela mocheso o feteletseng, ho netefatsa boleng bo tsitsitseng ba khatiso le botsitso ba lisebelisoa.

* Sistimi e Sebetsang ea ho Pholisa: Li-compressor tse sebetsang hantle le li-heaters tsa mocheso li tlosa mocheso ka katleho, esita le nakong ea mesebetsi e telele ea khatiso kapa lits'ebetso tsa mocheso o phahameng.

* Tlhokomelo le Lialamo tsa Nako ea 'Nete: E na le ponts'o e hlakileng bakeng sa tlhahlobo ea nako ea nnete le lialamo tsa liphoso tsa sistimi, e netefatsa ts'ebetso e bonolo.

* Taolo ea Remote ea RS485: Tlhokomelo le taolo e hole ka boikhethelo ka sebopeho sa RS485, se loketseng maemo a indasteri.

* E Sebetsa ka Motlakase: E entsoe ka likarolo tse bolokang matla ho fokotsa tšebeliso ea matla ntle le ho tela ho sebetsa hantle ha pholiso.

* Compact & Easy Ho Sebelisa: Moralo o bolokang sebaka o lumella ho kenya habonolo, 'me litaolo tse bonolo tsa basebelisi li netefatsa ts'ebetso e bonolo.

* Litifikeiti tsa Machabeng: Li netefalitsoe ho fihlela litekanyetso tse ngata tsa machabeng, tse netefatsang boleng le polokeho limmarakeng tse fapaneng.

* E tšoarella ebile e ea Tšepahala: E hahiloe molemong oa tšebeliso e tsoelang pele, e nang le lisebelisoa tse matla le ts'ireletso ea ts'ireletso, ho kenyeletsoa lialamo tse fetang nako le mocheso o feteletseng.

* Tiisetso ea Lilemo tse 2: E tšehetsoa ke tiisetso e felletseng ea lilemo tse 2, e netefatsang khotso ea kelello le ts'epo ea nako e telele.

* Phatlalatso e pharalletseng: E loketse lihatisi tse fapaneng tsa 3D, ho kenyeletsoa mechini ea SLS, SLM le DMLS.

Taolo ea mocheso habeli

Sehlopha sa taolo se bohlale se fana ka mekhoa e 'meli e ikemetseng ea ho laola mocheso. E 'ngoe ke ea ho laola mocheso oa laser fiber 'me e' ngoe ke ea ho laola mocheso oa optics.

Sekoti sa metsi a mabeli le sekoti sa metsi

Mehaho ea metsi le liphaephe tsa metsi li entsoe ka tšepe e sa hloekang ho thibela ho bola kapa ho lutla ha metsi.

Mabili a Caster bakeng sa ho tsamaea habonolo

Mabili a mane a caster a fana ka motsamao o bonolo le ho feto-fetoha ha maemo.

Re mona bakeng sa hau ha o re hloka.

Ka kopo tlatsa foromo ho ikopanya le rona, 'me re tla thabela ho u thusa.