Optimal Cooling Solution for 3000W Fiber Lasers in SLS SLM Metal 3D Printing Equipment

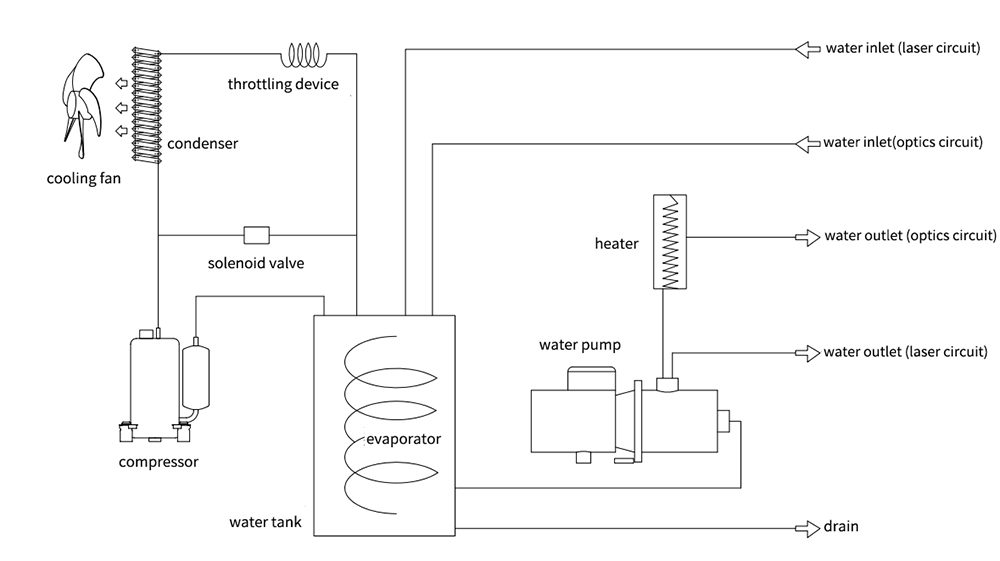

TEYU Industrial Chiller CWFL-3000 is a specialized cooling solution designed specifically for 3000W fiber laser sources used in metal 3D printing technologies like Selective Laser Sintering (SLS) and Selective Laser Melting (SLM). Its standout dual-cooling channel design allows for simultaneous cooling of both the laser and other critical components in the system, ensuring efficient heat dissipation and high-energy printing, improving the overall accuracy of the printed metal parts.

3D Printer Chiller CWFL-3000 offers precise temperature control, exceptional durability, and energy efficiency, making it ideal for industrial-scale SLS and SLM systems. It provides continuous and reliable cooling, enhancing the performance and lifespan of metal 3D printers while optimizing production efficiency and reducing operational costs. It is the perfect choice for users seeking a high-capacity, tailored cooling solution for their metal 3D printing operations.

Model: CWFL-3000

Machine Size: 77X55X103cm (L X W X H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CWFL-3000ANPTY | CWFL-3000BNPTY | CWFL-3000ENPTY |

| Voltage | AC 1P 220-240V | AC 1P 220-240V | AC 3P 380V |

| Frequency | 50Hz | 60Hz | 50Hz |

| Current | 5~33.3A | 3.6~30.9A | 2.1~14A |

|

Max. power consumption |

5.76kW | 6.05kW | 6.08kW |

|

Heater power |

600W+1400W | ||

| Precision | ±0.5℃ | ||

| Reducer | Capillary | ||

| Pump power | 0.75kW | 1kW | 0.75kW |

| Tank capacity | 22L | ||

| Inlet and outlet | Rp1/2”+Rp1” | ||

|

Max. pump pressure |

5 bar | 5.9 bar | 5 bar |

| Rated flow | 2L/min+>30L/min | ||

| N.W. | 93Kg | 87Kg | 105Kg |

| G.W. | 109Kg | 103Kg | 121Kg |

| Dimension | 77X55X103cm (L X W X H) | ||

| Package dimension | 78X65X117cm (L X W X H) | ||

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Precise Temperature Control: Maintains stable and accurate cooling to prevent overheating, ensuring consistent print quality and equipment stability.

* Efficient Cooling System: High-performance compressors and heat exchangers effectively dissipate heat, even during long print jobs or high-temperature applications.

* Real-Time Monitoring & Alarms: Equipped with an intuitive display for real-time monitoring and system fault alarms, ensuring smooth operation.

* RS485 Remote Control: Optional remote monitoring and control via RS485 interface, ideal for industrial environments.

* Energy-Efficient: Designed with energy-saving components to reduce power consumption without sacrificing cooling efficiency.

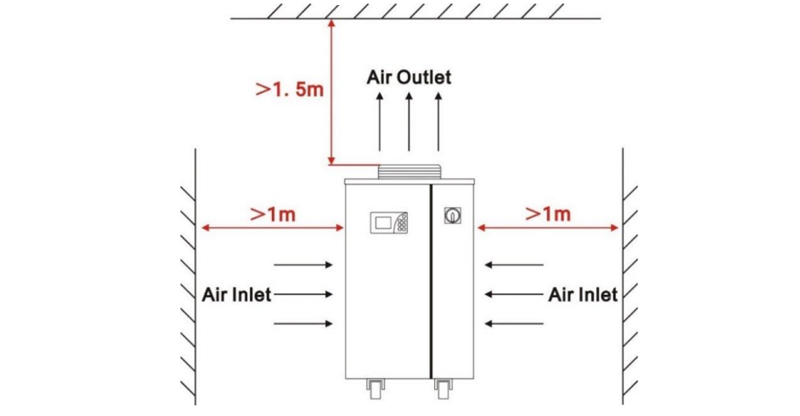

* Compact & Easy to Operate: Space-saving design allows for easy installation, and user-friendly controls ensure simple operation.

* International Certifications: Certified to meet multiple international standards, ensuring quality and safety in diverse markets.

* Durable & Reliable: Built for continuous use, with robust materials and safety protections, including overcurrent and over-temperature alarms.

* 2-Year Warranty: Backed by a comprehensive 2-year warranty, ensuring peace of mind and long-term reliability.

* Wide Compatibility: Suitable for various 3D printers, including SLS, SLM, and DMLS machines.

Dual temperature control

The intelligent control panel offers two independent temperature control systems. One is for controlling the temperature of the fiber laser and the other is for controlling the temperature of the optics.

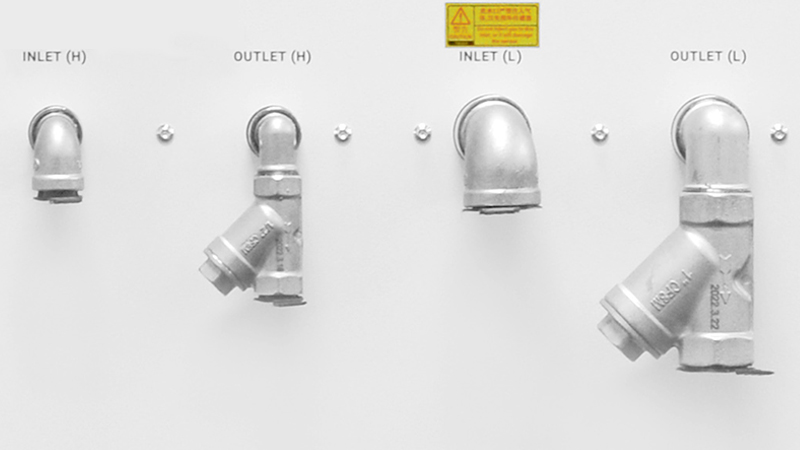

Dual water inlet and water outlet

Water inlets and water outlets are made from stainless steel to prevent potential corrosion or water leakage.

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.