Uma isiqandisi samanzi esiqandisini esipholisa umshini wokusika wensimbi we-fiber laser usesemazingeni okushisa aphezulu ngisho nangemva kokushintsha kwamanzi, abasebenzisi bangenza ukuhlola okulandelayo ngamunye ngamunye.

1.I-gauze yothuli ivinjiwe. Kunconywa ukuthi uyihlukanise futhi uyigeze ngezikhathi ezithile;2.Indawo yesiqandisi samanzi esiqandisisiwe ayingeni kahle umoya. Ngakho qiniseka ukuthi indawo ezungezile inomoya omuhle;

3.Gwema ukuvula nokuvala isiqandisi kaningi ukuze isiqandisi sibe nesikhathi esanele sokwenza isiqandisi;

4.Umthamo wokupholisa we-chiller yamanzi esiqandisini mancane kakhulu. Ngakho-ke kungcono ukushintshela kwenkulu;

5.Isilawuli sezinga lokushisa siphukile futhi sibonisa ukufunda okungalungile. Ngakho-ke kungcono ukufaka entsha esikhundleni.

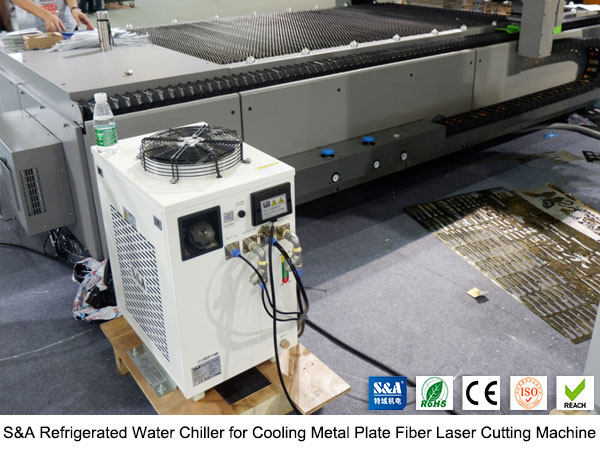

Ngemuva kokuthuthuka kweminyaka engu-18, sisungula uhlelo oluqinile lwekhwalithi yomkhiqizo futhi sinikeza isevisi esekelwe ngemuva kokuthengisa. Sinikeza amamodeli angaphezu kuka-90 ajwayelekile okupholisa amanzi kanye namamodeli angu-120 wokupholisa amanzi ukuze wenze ngokwezifiso. Ngomthamo wokupholisa osukela ku-0.6KW kuya ku-30KW, izishicileli zethu zamanzi zisebenza emithonjeni ehlukene ye-laser, imishini yokucubungula i-laser, imishini ye-CNC, amathuluzi ezokwelapha, imishini yaselabhorethri nokunye.