A laser chiller is prone to the common failures in high-temperature summer: ultrahigh room temperature alarm, the chiller is not cooling and the circulating water deteriorates, and we should know how to deal with it.

Common faults and solutions of industrial chillers in hot summer

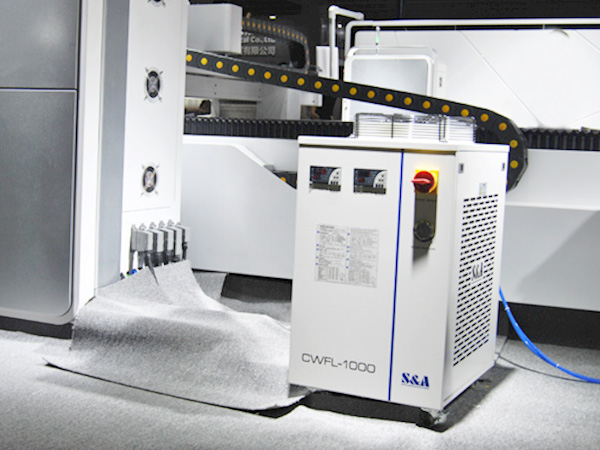

We usually have iced watermelons, sodas, ice creams and other cool things to spend the hot summer. So has your laser equipment also installed a cooling tool - a laser chiller to spend its hot days? A laser chiller, as an indispensable cooling device in the operation of laser equipment, protects the stable operation of the laser throughout the process. A laser chiller is prone to the following failures in high-temperature summer:

1. Ultrahigh room temperature alarm. When the room temperature is too high, the room temperature ultrahigh alarm is prone to occur, and the alarm code and the water temperature are displayed alternately, which is accompanied by a beeping sound. At this time, the chiller should be installed in a ventilated and cool place, and the room temperature should below 40 degrees, which can avoid the alarm of ultrahigh room temperature and affect the cooling effect.

2. The chiller is not cooling. In other seasons, the temperature is not very high, and the cooling of the chiller is stable, but in summer, the cooling of the chiller is not up to the standard. What is the reason? It turns out that the room temperature is too high, which affects the cooling and cooling of the chiller itself. It is recommended to replace it with a chiller with a higher cooling capacity to avoid such a situation. After long-term use, the dust on the dustproof net will accumulate more and more, which will also affect the heat dissipation of the chiller. It needs to be cleaned with an air gun regularly.

3. The circulating water deteriorates. In summer, the circulating water is easy to deteriorates due to high temperature, which affects the circulating water circuit of the chiller and causes blockage. It is recommended to replace the circulating water every three months.

The above are the common chillers faults and chillers troubleshooting methods in hot summer. S&A chiller has 20 years of experience in the refrigeration industry. It is mainly engaged in the research and development, and production of various types of laser chillers, which provides users with suitable refrigeration solutions.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.