Fiber laser and CO2 glass tube laser are the most common lasers in the current market with the former one being mostly applied in cutting, welding and cladding while the latter one being mostly applied in marking and fabric cutting. These two types of lasers share one thing in common: circulating water chiller is necessary to be equipped for cooling the lasers in order to guarantee the normal and the stable working of the lasers. A Russian customer of S&A Teyu, who previously produces fiber laser, is now also developing CO2 glass tube lasers. He recently contacted S&A Teyu for selecting the appropriate circulating water chiller models for his CO2 lasers with different powers. In the end, he selected S&A Teyu as his circulating water chiller supplier.

In addition, S&A Teyu summarizes the following model selections suggestions:

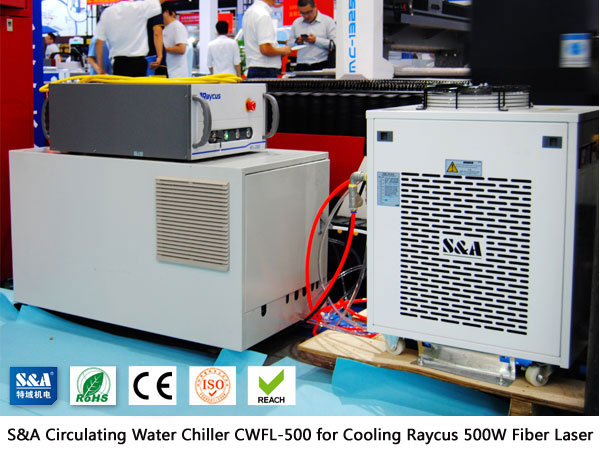

For cooling 500W-4000W fiber laser:

500W fiber laser -- S&A Teyu CWFL-500 laser chiller

800W fiber laser -- S&A Teyu CWFL-800 laser chiller

1000W fiber laser -- S&A Teyu CWFL-1000 laser chiller

1500W fiber laser -- S&A Teyu CWFL-1500 laser chiller

2000W fiber laser -- S&A Teyu CWFL-2000 laser chiller

3000W fiber laser -- S&A Teyu CWFL-3000 laser chiller

4000W fiber laser -- S&A Teyu CWFL-4000 laser chiller

For cooling 100W-300W CO2 glass tube laser:

100W CO2 glass tube laser -- S&A Teyu CW-5000 water chiller

130W CO2 glass tube laser -- S&A Teyu CW-5200 water chiller

150W CO2 glass tube laser -- S&A Teyu CW-5300 water chiller

200W CO2 glass tube laser -- S&A Teyu CW-5300 water chiller

300W CO2 glass tube laser -- S&A Teyu CW-6000 water chiller

In respect of production, S&A Teyu has invested the production equipment of more than one million yuan, ensuring the quality of a series of processes from the core components (condenser) of industrial chiller to the welding of sheet metal; in respect of logistics, S&A Teyu has set up logistics warehouses in the main cities of China, having greatly reduced the damage due to the long-distance logistics of the goods, and improved transport efficiency; in respect of after-sales service, the warranty period is two years.