Heater

Filter

US standard plug / EN standard plug

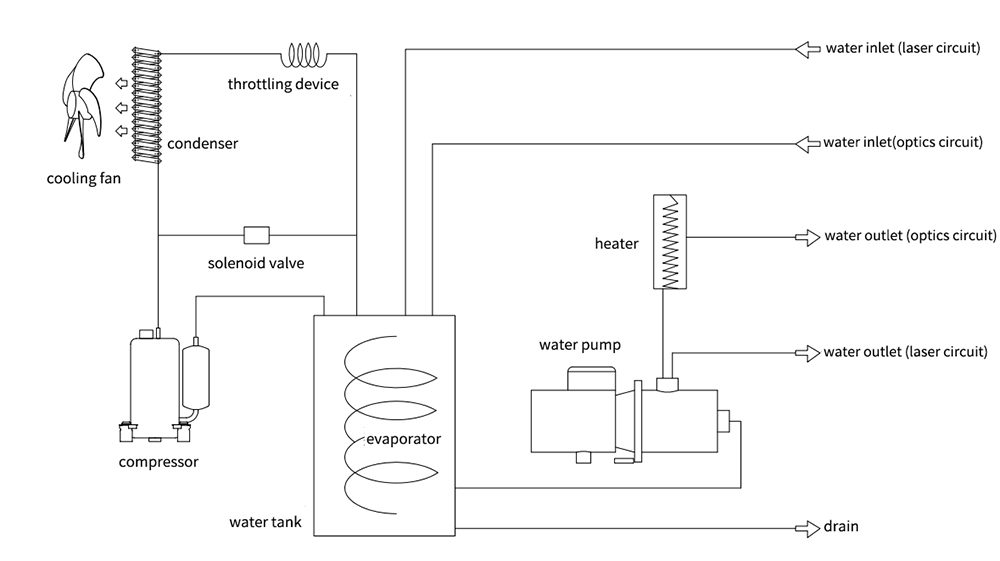

Closed loop chiller system CWFL-500 is designed especially for 500W fiber laser to guarantee its robust running. Offering two water channels in one housing, this process cooling chiller is capable of cooling the fiber laser and the optics simultaneously. Users no longer have to worry about taking up space. With dual temperature control mode offered, users can manually set the water temperature or leave the water temperature automatically adjusting itself. This dual-temperature dual-control design of the chiller provides a remarkable temperature control solution for fiber laser in all directions.

Model: CWFL-500

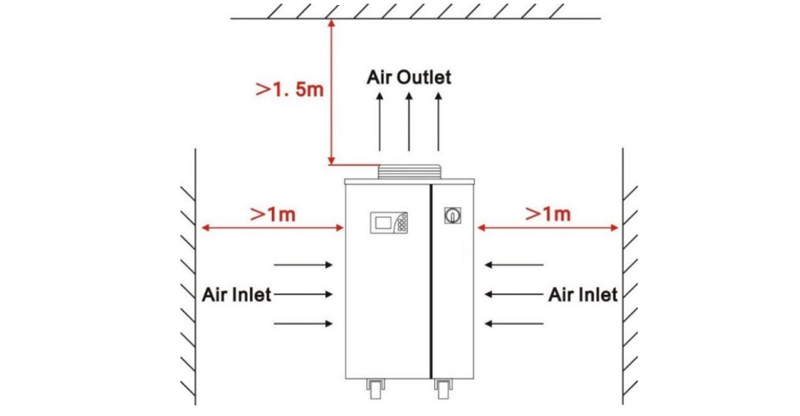

Machine Size: 65 X 38 X 74cm (L X W X H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CWFL-500AN | CWFL-500BN | CWFL-500DN |

| Voltage | AC 1P 220-240V | AC 1P 220-240V | AC 1P 110V |

| Frequency | 50Hz | 60Hz | 60Hz |

| Current | 3.4~11.5A | 3.9~12A | 8.8~25.1A |

| Machine power | 2.0kW | 2.03kW | 2.06kW |

| Electric assisted power | 600W+ 600W | ||

| Precision | ±0.3℃ | ||

| Reducer | Capillary | ||

| Pump power | 0.55kW | 0.75kW | 0.55kW |

| Tank capacity | 10L | ||

| Inlet and outlet | Rp1/2"+Rp1/2" | ||

| Lift | 44M | 53M | 45M |

| Rated flow | 2L/min + >8L/min | ||

| N.W. | 56Kgs | 58Kgs | |

| G.W. | 62Kgs | 64Kgs | |

| Dimension | 65 X 38 X 74cm (L X W X H) | ||

| Package dimension | 68 X 53 X 92cm (L X W X H) | ||

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Dual cooling circuit

* Active cooling

* Temperature stability: ±0.3°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410a

* User-friendly controller interface

* Integrated alarm functions

* Back mounted fill port and visual water level

* Optimized for high performance at low temperatures

* Ready for immediate use

Heater

Filter

US standard plug / EN standard plug

Dual temperature control

The intelligent control panel offers two independent temperature control systems. One is for controlling the temperature of the fiber laser and the other is for controlling the temperature of the optics.

Dual water inlet and water outlet

Water inlets and water outlets are made from stainless steel to prevent potential corrosion or water leakage.

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.