Los ntawm kev txiav txim siab txog cov khoom siv, laser tsis, thiab cov tswv yim txheej txheem, tsab xov xwm no muaj cov tswv yim daws teeb meem rau laser tu hauv qhov chaw muaj kev pheej hmoo siab. Cov txheej txheem no tsom xyuas kom muaj kev tu kom zoo thaum txo qhov muaj peev xwm rau cov khoom puas tsuaj-ua rau laser ntxuav kom nyab xeeb thiab txhim khu kev qha rau cov ntaub ntawv rhiab thiab nyuaj.

Laser Cleaning Solutions: Tackling Cov Kev Sib Tw hauv Cov Khoom Uas Muaj Teeb Meem Siab

Laser tu tau tshwm sim raws li kev ua tau zoo, tsis muaj kev sib cuag precision tshem tawm tshuab. Txawm li cas los xij, thaum cuam tshuam nrog cov ntaub ntawv rhiab, nws yog ib qho tseem ceeb rau kev sib npaug ntawm kev tu kom zoo nrog kev tiv thaiv cov khoom. Tsab ntawv xov xwm no nthuav tawm txoj hauv kev los daws cov teeb meem kev pheej hmoo siab los ntawm kev txheeb xyuas cov yam ntxwv ntawm cov khoom, laser tsis, thiab cov txheej txheem tsim.

Kev puas tsuaj rau cov cuab yeej thiab kev tiv thaiv rau cov khoom siv phom sij hauv Laser tu

1. Cov khoom siv cua sov

Kev puas tsuaj: Cov khoom uas muaj cov ntsiab lus melting tsawg lossis cov thermal conductivity tsis zoo - xws li cov yas lossis roj hmab - yog qhov ua rau softening, carbonization, los yog deformation vim thaum tshav kub kub buildup thaum lub sij hawm laser tu.

Cov kev daws teeb meem: (1) Rau cov ntaub ntawv xws li yas thiab roj hmab: Siv cov tshuab hluav taws xob qis qis ua ke nrog cov roj inert (xws li, nitrogen) txias. Pulse spacing kom zoo tso cai rau kom muaj cua sov kom zoo, thaum cov roj inert pab cais cov pa oxygen, txo qis oxidation. (2) Rau cov ntaub ntawv ntxeem tau xws li ntoo lossis ceramic: Siv lub zog qis, luv-mem tes lasers nrog ntau yam tshuaj ntsuam. Cov txheej txheem porous sab hauv pab ua kom lub zog hluav taws xob tawg los ntawm kev rov qab xav dua, txo qhov kev pheej hmoo ntawm cov cua sov hauv zos.

2. Cov khoom siv ntau txheej txheej

Kev puas tsuaj rau lub cev: Qhov sib txawv ntawm lub zog nqus ntawm cov khaubncaws sab nraud povtseg tuaj yeem ua rau tsis muaj kev puas tsuaj rau lub substrate lossis ua rau txheej txheej txheej.

Cov kev daws teeb meem: (1) Rau cov xim pleev xim los yog coated composites: Kho lub laser qhov teeb meem lub kaum sab xis los hloov txoj kev xav. Qhov no txhim kho kev sib cais sib cais thaum txo lub zog nkag mus rau hauv lub substrate. (2) Rau coated substrates (piv txwv li, chrome-plated pwm): Siv ultraviolet (UV) lasers nrog cov wavelengths tshwj xeeb. UV lasers tuaj yeem xaiv ablate lub txheej yam tsis hloov cov cua kub ntau dhau, txo kev puas tsuaj rau cov khoom siv hauv qab.

3. High-Hardness thiab brittle cov ntaub ntawv

Kev puas tsuaj: Cov ntaub ntawv xws li iav los yog ib qho crystal silicon tuaj yeem tsim microcracks vim qhov sib txawv ntawm thermal expansion lossis hloov pauv ntawm cov qauv siv lead ua.

Kev daws: (1) Rau cov ntaub ntawv xws li iav los yog monocrystalline silicon: Siv ultra-luv mem tes lasers (xws li, femtosecond lasers). Lawv nonlinear nqus tau ua rau lub zog hloov mus ua ntej kev co tuaj yeem tshwm sim, txo qhov kev pheej hmoo ntawm microcracks. (2) Rau carbon fiber composites: Siv beam-shaping cov tswv yim, xws li annular beam profiles, los xyuas kom meej lub zog sib xws thiab txo cov kev ntxhov siab concentration ntawm resin-fiber interfaces, uas pab tiv thaiv kev tawg.

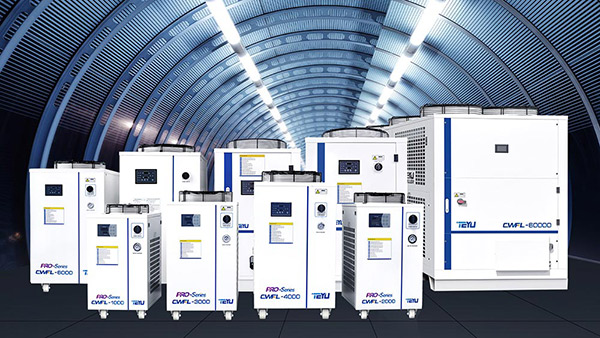

Industrial Chillers : Ib qho tseem ceeb hauv kev tiv thaiv cov ntaub ntawv thaum lub sij hawm laser tu

Cov chillers muaj lub luag haujlwm tseem ceeb hauv kev txo qis kev pheej hmoo ntawm cov khoom puas tsuaj los ntawm cov cua kub sib xyaw thaum lub sij hawm ntxuav laser. Lawv qhov kub thiab txias tswj kom ruaj khov laser tso zis zog thiab beam zoo nyob rau hauv ntau yam kev ua haujlwm. Kev siv hluav taws xob zoo tiv thaiv kom tsis txhob muaj cua sov ntawm cov ntaub ntawv kub-rhiab heev, tsis txhob softening, carbonization, lossis deformation.

Ntxiv nrog rau kev tiv thaiv cov ntaub ntawv, chillers tseem tiv thaiv cov khoom siv laser thiab cov khoom siv kho qhov muag, ua kom cov khoom siv ntev ntev. Nruab nrog cov yam ntxwv ntawm kev nyab xeeb, cov chillers muaj kev ceeb toom ntxov thiab kev tiv thaiv tsis siv neeg thaum muaj kev ua haujlwm tsis zoo, txo qhov kev pheej hmoo ntawm cov khoom siv tsis ua haujlwm lossis teeb meem kev nyab xeeb.

Xaus

Los ntawm kev txiav txim siab txog cov khoom siv, laser tsis, thiab cov tswv yim txheej txheem, tsab xov xwm no muaj cov tswv yim daws teeb meem rau laser tu hauv qhov chaw muaj kev pheej hmoo siab. Cov txheej txheem no tsom xyuas kom muaj kev tu kom zoo thaum txo qhov muaj peev xwm rau cov khoom puas tsuaj-ua rau laser ntxuav kom nyab xeeb thiab txhim khu kev qha rau cov ntaub ntawv rhiab thiab nyuaj.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.