Nekunyatsofunga nezve zvivakwa zvezvinhu, laser paramita, uye maitiro ekuita, chinyorwa ichi chinopa mhinduro dzinoshanda dzekuchenesa laser munzvimbo dzine njodzi huru. Idzi nzira dzinovavarira kuona kucheneswa kwakanaka uku uchideredza mukana wekukuvadza kwezvinhu-kuita kuti laser yekuchenesa ive yakachengeteka uye yakavimbika kune yakaoma uye yakaoma maapplication.

Laser Yekuchenesa Solutions: Kugadzirisa Matambudziko muYakanyanya-Njodzi Material Kugadziriswa

Laser yekuchenesa yakabuda seyakanyanya kushanda, isiri-yekubata chaiyo yekubvisa tekinoroji. Nekudaro, kana uchibata nezvinhu zvine hunyoro, zvakakosha kuti uenzanise kushanda kwekuchenesa nekudzivirira kwezvinhu. Ichi chinyorwa chinopa yakarongeka nzira yekugadzirisa yakanyanya-njodzi mamiriro nekuongorora hunhu hwezvinhu, laser paramita, uye dhizaini dhizaini.

Kukuvadza Mechanism uye Countermeasures Yepamusoro-Njodzi Zvishandiso muLaser Kuchenesa.

1. Heat-Sensitive Materials

Damage Mechanism: Zvishandiso zvine nzvimbo dzakanyunguduka dzakaderera kana kusafamba zvakanaka kwemafuta-senge mapurasitiki kana rabha-zvinongoita kupfava, carbonization, kana deformation nekuda kwekupisa kuvakwa panguva yekuchenesa laser.

Solutions: (1) Zvemidziyo yakaita semapurasitiki nerabha: Shandisa yakaderera-simba pulsed lasers akasanganiswa neinert gasi (semuenzaniso, nitrogen) kutonhora. Yakafanira pulse spacing inobvumira kuparara kwekupisa, nepo inert gasi ichibatsira kutsaura okisijeni, kuderedza oxidation. (2) Pazvinhu zvine porous sehuni kana ceramic: Isa yakaderera-simba, pfupi-pulse lasers ine akawanda scans. Iyo porous yemukati chimiro inobatsira kuparadzira laser simba kuburikidza nekudzokororwa kufungisisa, kuderedza njodzi yekupisa kwenzvimbo.

2. Multi-Layer Composite Materials

Kukuvadza Mechanism: Iwo akasiyana simba absorption mwero pakati pematanho anogona kukonzera kukuvadza kusiri nemaune kune substrate kana kutungamirira kukuvhara kwekuvhara.

Solutions: (1) Zvesimbi dzakapendwa kana coated composites: Rongedza kona yechiitiko chelaser kuti uchinje nzira yekuratidzira. Izvi zvinosimudzira kupatsanurwa kwechimiro uku ichideredza simba rekupinda mu substrate. (2) Kune akavharidzirwa substrates (semuenzaniso, chrome-plated molds): Shandisa ultraviolet (UV) lasers ane chaiwo wavelengths. UV lasers inogona kusarudza kubvisa iyo yekupotera pasina kuendesa kupisa kwakanyanya, kuderedza kukuvadzwa kune iri pasi zvinhu.

3. High-Hardness uye Brittle Materials

Kukuvadza Mechanism: Zvishandiso zvakadai segirazi kana imwe-crystal silicon inogona kugadzira microcracks nekuda kwekusiyana kwekuwedzera kwekushisa kana kuchinja kamwe kamwe mukristal chimiro.

Solutions: (1) Zvemidziyo yakaita segirazi kana monocrystalline silicon: Shandisa ultra-short pulse lasers (semuenzaniso, femtosecond lasers). Kunyura kwavo kusingaite kunogonesa kufambisa kwesimba kusati kwaitika kudengenyeka kwereti, zvichideredza njodzi yemakrocracks. (2) Kune kabhoni fiber composites: Shandisa maitiro ekugadzira danda, senge annular beam profiles, kuve nechokwadi chekugovera simba rakafanana uye kuderedza kushushikana kwekushushikana pane resin-fiber interfaces, iyo inobatsira kudzivirira kuputika.

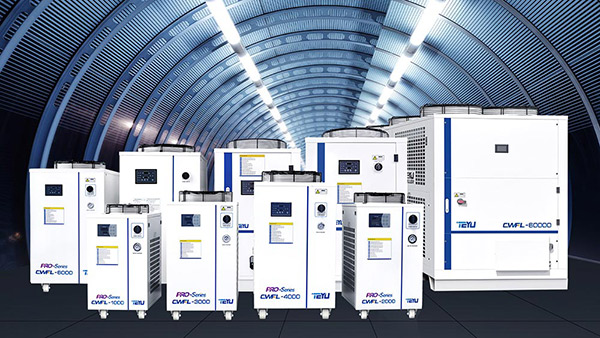

Industrial Chillers : Mubatsiri Akakosha Mukudzivirira Zvishandiso Panguva Yekuchenesa Laser

Industrial chillers inoita basa rakakosha mukudzikisa njodzi yekukuvara kwezvinhu kunokonzerwa nekuunganidza kupisa panguva yekuchenesa laser. Yavo chaiyo tembiricha yekudzora inovimbisa yakagadzikana laser kubuda simba uye danda mhando pasi pemamiriro akasiyana ekushanda. Kunyatsopisa kupisa kunodzivirira kupisa kwezvinhu zvinonzwa kupisa, kudzivirira kupfava, carbonization, kana deformation.

Pamusoro pekudzivirira zvinhu, machiller anochengetedzawo masosi e laser uye optical components, achiwedzera hupenyu hwemidziyo. Akashongedzerwa neakavakirwa-mukati maficha ekuchengetedza, maindasitiri anotonhorera anopa yambiro yekutanga uye otomatiki dziviriro kana ikasashanda, kuderedza njodzi yekukundikana kwemidziyo kana zviitiko zvekuchengetedza.

Mhedziso

Nekunyatsofunga nezve zvivakwa zvezvinhu, laser paramita, uye maitiro ekuita, chinyorwa ichi chinopa mhinduro dzinoshanda dzekuchenesa laser munzvimbo dzine njodzi huru. Idzi nzira dzinovavarira kuona kucheneswa kwakanaka uku uchideredza mukana wekukuvadza kwezvinhu-kuita kuti laser yekuchenesa ive yakachengeteka uye yakavimbika kune yakaoma uye yakaoma maapplication.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.