Hauv kev hloov kho hluav taws xob tsim kev lag luam, Surface Mount Technology (SMT) yog qhov tseem ceeb. Kev tswj qhov kub thiab av noo, tswj xyuas los ntawm cov khoom siv cua txias xws li dej chillers, xyuas kom muaj kev ua haujlwm zoo thiab tiv thaiv qhov tsis xws luag. SMT txhim khu kev ua tau zoo, kev ua tau zoo, thiab txo cov nqi thiab kev cuam tshuam ib puag ncig, ntxiv rau qhov tseem ceeb rau kev nce qib yav tom ntej hauv kev tsim hluav taws xob.

Surface Mount Technology (SMT) thiab Nws Daim Ntawv Thov hauv Kev Tsim Kho Ib puag ncig

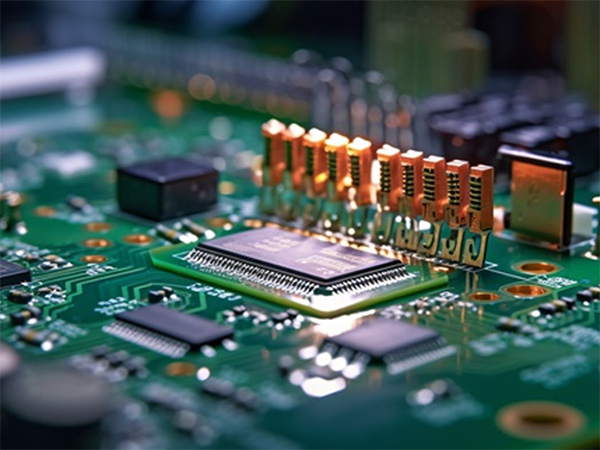

Hauv kev lag luam hluav taws xob tsim hluav taws xob tam sim no hloov zuj zus mus, Surface Mount Technology (SMT) ua lub luag haujlwm tseem ceeb. SMT thev naus laus zis suav nrog qhov tseeb tso ntawm cov khoom siv hluav taws xob mus rau Printed Circuit Boards (PCBs) uas tsis yog tsuas yog tsav lub miniaturization, lub teeb yuag, thiab txhim kho kev ua tau zoo ntawm cov khoom siv hluav taws xob, tab sis kuj tseem txhim kho cov khoom lag luam kev ntseeg siab thiab kev tsim khoom zoo thaum txo cov nqi tsim khoom.

Cov txheej txheem yooj yim ntawm SMT Surface Mounting

Cov txheej txheem ntawm SMT nto mounting yog qhov tseeb thiab muaj txiaj ntsig, suav nrog ob peb kauj ruam tseem ceeb:

Solder Paste Printing: Thov muab tshuaj txhuam rau hauv cov ntaub qhwv tshwj xeeb ntawm PCB los npaj rau kev sib xyaw ua ke ntawm qhov chaw.

Part Mounting: Siv cov txheej txheem siab-precision deg mount system los tso cov khoom siv hluav taws xob mus rau hauv cov ntaub so ntswg.

Reflow Soldering: Melting lub solder muab tshuaj txhuam rau hauv qhov cub reflow los ntawm cov cua kub ncig kom ruaj khov rau cov khoom siv hluav taws xob rau PCB.

Automated Optical Inspection (AOI): AOI cov cav tov tshuaj xyuas qhov zoo ntawm cov PCB soldered kom tsis txhob muaj qhov tsis xws luag xws li qhov tsis ncaj ncees lawm, qhov ploj, lossis rov qab.

X-Ray Kev Tshawb Fawb: Siv cov khoom siv xoo hluav taws xob soj ntsuam rau kev tswj hwm qib zoo ntawm cov pob qij txha zais, xws li cov ntim hauv Pob Grid Array (BGA).

Kev tswj qhov kub thiab txias yuav tsum muaj nyob rau hauv ib puag ncig ntau lawm

SMT cov kab ntau lawm muaj cov qauv nruj rau qhov kub thiab txias hauv qhov chaw ua haujlwm. Kev tswj qhov kub thiab txias yog qhov tseem ceeb rau kev tswj cov khoom ruaj khov thiab cov khoom zoo, tshwj xeeb tshaj yog nyob rau hauv qhov kub thiab txias:

Cov cuab yeej ntsuas kub: SMT cov cuab yeej, tshwj xeeb tshaj yog cov tshuab mounting thiab reflow ncu, ua kom muaj cua sov tseem ceeb thaum ua haujlwm. Cov cuab yeej txias txias tiv thaiv overheating thiab ua kom ruaj khov ua haujlwm tsis tu ncua.

Cov txheej txheem tshwj xeeb yuav tsum muaj: Cov khoom siv cua txias yuav pab tswj kom muaj qhov kub thiab txias ib puag ncig rau cov khoom kub-rhiab heev lossis cov txheej txheem tshwj xeeb.

Cov cuab yeej ua kom txias xws li cov dej chillers yog qhov tseem ceeb rau kev txhawb nqa kev ua haujlwm zoo ntawm cov kab ntau lawm, tiv thaiv kev tsis xws luag lossis kev ua haujlwm degradation los ntawm qhov kub thiab txias.

Environmental Advantages ntawm SMT Surface Mounting

SMT thev naus laus zis tsim cov khoom pov tseg tsawg kawg thaum lub sijhawm tsim khoom, uas yooj yim rau rov siv dua thiab pov tseg. Qhov no ua rau SMT ua thev naus laus zis ib puag ncig tus phooj ywg thiab lub zog txuag. Niaj hnub no lub ntiaj teb no tsom ntsoov rau kev tiv thaiv ib puag ncig thiab kev txhim kho kom ruaj khov, SMT thev naus laus zis tau maj mam dhau los ua cov txheej txheem nyiam hauv kev lag luam hluav taws xob tsim khoom.

SMT nto mount tshuab yog lub zog tsav tom qab kev nce qib ntawm kev lag luam hluav taws xob tsim khoom. Nws tsis tsuas yog txhim kho kev ua tau zoo thiab kev ua haujlwm ntawm cov khoom siv hluav taws xob, tab sis kuj tseem ua rau txo cov nqi tsim khoom thiab txo qhov cuam tshuam ib puag ncig. Nrog kev txhim kho thev naus laus zis tsis tu ncua, SMT nto mounting yuav txuas ntxiv ua lub luag haujlwm tseem ceeb hauv kev tsim hluav taws xob yav tom ntej.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.