Kumashishini okuvelisa izinto zombane, iSurface Mount Technology (SMT) ibalulekile. Ulawulo olungqongqo lweqondo lobushushu kunye nokufuma, olulondolozwe zizixhobo zokupholisa ezifana nezikhenkcezisi zamanzi, luqinisekisa ukusebenza kakuhle nokuthintela iziphene. I-SMT yongeza ukusebenza, ukusebenza kakuhle, kwaye inciphisa iindleko nefuthe lokusingqongileyo, ishiyeke ingundoqo kwinkqubela phambili yexesha elizayo kwimveliso yombane.

I-Surface Mount Technology (SMT) kunye neSicelo sayo kwiNdawo yoMveliso

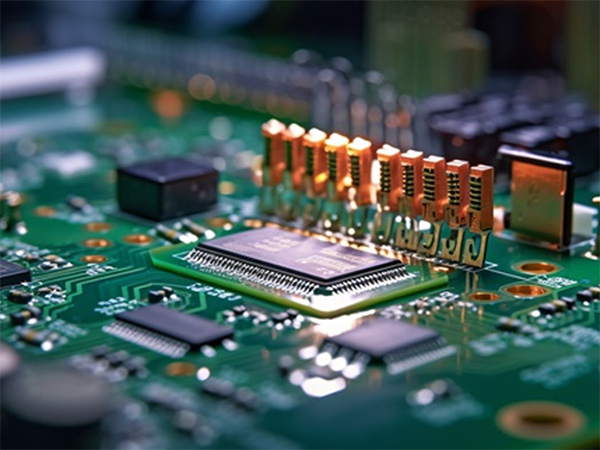

Kumashishini anamhlanje avela ngokukhawuleza okwenziwa kwezixhobo zombane, iSurface Mount Technology (SMT) idlala indima ebalulekileyo. Itekhnoloji ye-SMT ibandakanya ukubekwa ngokuthe ngqo kwamacandelo e-elektroniki kwiiBhodi zeSekethe eziShicileleyo (iiPCB) ezingakhange ziqhubele nje ukwenziwa kweminiaturization, ukukhaphukhaphu, kunye nokusebenza okuphuculweyo kweemveliso zombane, kodwa kuphuculwe ngokubonakalayo ukuthembeka kwemveliso kunye nempumelelo yokwenziwa ngelixa kuncitshiswa iindleko zemveliso.

Inkqubo eSisiseko ye-SMT yokuNqanyiswa koMphezulu

Inkqubo yokunyuswa komphezulu we-SMT ichanekile kwaye iyasebenza, iquka amanyathelo angundoqo aliqela:

Ushicilelo lwe-Solder Cola: Ukufaka i-solder pads kwiiphedi ezithile kwi-PCB ukulungiselela ukunyuswa kwecandelo elichanekileyo.

Ukuxhonywa kweNxalenye: Ukusebenzisa isixokelelwano sokuxhoma somgangatho ophezulu esichanekileyo ukubeka izinto ze-elektroniki kwiipads ezincamathisiweyo.

I-Reflow Soldering: Ukunyibilikisa intlama ye-solder kwi-oven yokubuyisela ngokujikeleza komoya oshushu ukuze ubophe ngokuqinileyo amacandelo e-elektroniki kwi-PCB.

Uhlolo oluzenzekelayo lwe-Optical Inspection (AOI): Oomatshini be-AOI bahlola umgangatho we-PCB ethengisiweyo ukuqinisekisa ukuba akukho ziphene ezifana namalungu angalunganga, iindawo ezingekhoyo, okanye umva.

Ukuhlolwa kwe-X-Ray: Ukusebenzisa izixhobo zokuhlola ze-X-reyi zokulawula umgangatho onzulu wezinto ezifihliweyo ze-solder, ezifana nezo zifakwe kwi-Ball Grid Array (BGA) yokupakisha.

IiMfuno zoLawulo loBuqondo kwiNdawo zeMveliso

Imigca yemveliso ye-SMT inemigangatho engqongqo yobushushu kunye nokufuma kwindawo yokusebenza. Ulawulo lobushushu lubalulekile ekugcineni uzinzo lwezixhobo kunye nomgangatho wokuthengisa, ngakumbi kwiindawo ezinobushushu obuphezulu:

Izixhobo zokulawula ubushushu: Izixhobo ze-SMT, ngokukodwa iinkqubo zokubeka phezulu kunye nee-ovens eziphinda ziphume, zenza ukushisa okukhulu ngexesha lokusebenza. Izixhobo zokupholisa ezichanekileyo zithintela ukushisa ngokugqithiseleyo kwaye ziqinisekisa ukusebenza okuqhubekayo okuzinzileyo.

Iimfuno zeNkqubo eKhethekileyo: Izixhobo zokupholisa zinceda ukugcina indawo efunekayo yobushushu obuphantsi kumacandelo anobunzulu bobushushu okanye iindlela ezithile zokuthambisa.

Izixhobo zokupholisa ezifana nezixhobo zokupholisa amanzi kwimizi-mveliso zibalulekile ukuze kugcinwe ukusebenza kakuhle kwemigca yokuvelisa, ukuthintela iziphene ze-soldering okanye ukuthotywa kokusebenza okubangelwa ngamaqondo obushushu agqithisileyo.

Izinto eziluncedo zokusiNgqongileyo zokuFaka umphezulu we-SMT

Itekhnoloji ye-SMT ivelisa inkunkuma encinci ngexesha lenkqubo yokwenziwa kwemveliso, ekulula ukuyihlaziya nokuyilahla. Oku kwenza ukuba ubuchwephesha bokusebenza kwe-SMT buvumelane nokusingqongileyo kwaye busebenzise amandla. Kugxininiso lwanamhlanje lwehlabathi kukhuselo lokusingqongileyo kunye nophuhliso oluzinzileyo, ithekhnoloji ye-SMT ngokuthe ngcembe iba yinkqubo ekhethwayo kushishino lokwenziwa kombane.

Itekhnoloji ye-SMT yokuphakama komphezulu ingamandla aqhuba ukuqhubela phambili koshishino lokwenziwa kombane. Ayiphuculi kuphela ukusebenza kunye nokuphumelela kwemveliso yeemveliso ze-elektroniki kodwa inegalelo ekunciphiseni iindleko zokwenziwa kunye nokunciphisa impembelelo yokusingqongileyo. Ngenkqubela phambili yobuchwepheshe eqhubekayo, ukunyuswa komphezulu we-SMT kuya kuqhubeka ukudlala indima ephambili kwikamva lokwenziwa kombane.

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.