Raws li kev siv thev naus laus zis txuas ntxiv mus, 3D luam ntawv tau ua nws txoj hauv kev mus rau hauv thaj chaw ntawm aerospace, xav tau cov kev xav tau meej ntxiv. Qhov tseem ceeb cuam tshuam rau qhov zoo ntawm 3D tshuab luam ntawv yog qhov kub thiab txias, thiab TEYU dej chiller CW-7900 ua kom pom qhov txias txias rau 3D tshuab luam ntawv ntawm cov foob pob hluav taws.

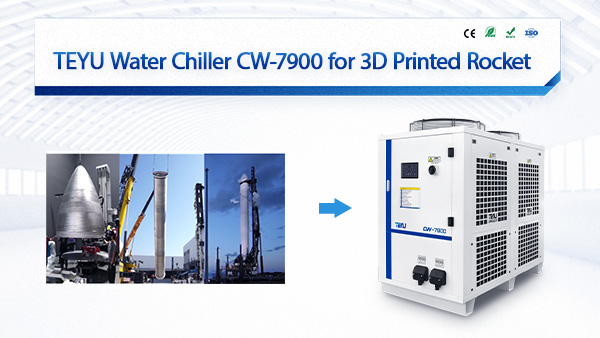

Ntiaj teb thawj 3D Luam Rocket Launched: TEYU Dej Chillers rau Txias 3D Printers

Thaum Lub Peb Hlis 23, 2023, lub ntiaj teb tau pom qhov kev tshaj tawm thawj zaug 3D luam tawm foob pob hluav taws tsim los ntawm Relativity Space. Sawv ntawm qhov siab ntawm 33.5 meters, lub foob pob hluav taws 3D luam tawm no tau lees tias yog qhov loj tshaj plaws 3D luam tawm khoom sim rau kev ya davhlau. Kwv yees li ntawm 85% ntawm lub foob pob hluav taws cov khoom, suav nrog nws cuaj lub cav, tau tsim los siv 3D tshuab luam ntawv.

Txawm hais tias lub foob pob hluav taws 3D luam tawm no tau ua tiav hauv nws qhov kev sim thib peb, qhov "anomaly" tshwm sim thaum sib cais ntawm theem thib ob, tiv thaiv nws los ntawm kev mus txog qhov xav tau. Raws li kev siv thev naus laus zis txuas ntxiv mus, 3D luam ntawv tau ua nws txoj hauv kev mus rau hauv thaj chaw ntawm aerospace, xav tau cov kev xav tau meej ntxiv.

Qhov tseem ceeb cuam tshuam rau qhov zoo ntawm 3D Printing Technology: Kub Tswjhwm

Lub taub hau ntawm lub tshuab luam ntawv 3D ua haujlwm los ntawm ob txoj kev hloov hluav taws xob: thermal conduction thiab thermal convection. Thaum lub sij hawm luam ntawv, cov khoom luam ntawv yog rhuab nyob rau hauv lub cua sov chamber mus rau lub xeev cov kua, kom zoo melting, zoo heev nplaum txaus, haum filament dav, thiab muaj zog adhesion. Cov txheej txheem thermal conduction no lav qhov zoo ntawm cov khoom luam tawm.

Txhawm rau kom ua tiav cov txheej txheem luam ntawv du, ua raws li cov qauv, thiab kom tsis txhob muaj qhov kub siab lossis qis qis hauv chav cua sov, kev tswj qhov kub thiab txias yog qhov tseem ceeb. Yog tias qhov kub thiab txias dhau lawm, kev siv cov cua txias yuav tsum tau txo qis, yog li pib cov txheej txheem thermal convection.

Nyob rau hauv cov txheej txheem luam ntawv, yog tias qhov kub thiab txias dhau lawm, lub qhov hluav taws xob nozzle tuaj yeem ua nplaum, cuam tshuam rau kev siv tau ntawm cov khoom luam tawm thiab tseem ua rau deformation. Hloov pauv, yog tias qhov kub thiab txias qis dhau, cov khoom siv khov kho nrawm nrawm, tiv thaiv kev sib raug zoo nrog lwm cov ntaub ntawv thiab ua rau cov nozzle clogging, cuam tshuam qhov kev ua tiav ntawm kev luam ntawv tiav.

Dej Chiller Ua kom muaj cua txias zoo tshaj plaws rau 3D tshuab luam ntawv

TEYU tshwj xeeb hauv kev lag luam circulating dej chillers , khav tshaj 21 xyoo ntawm kev tshawb fawb thiab kev loj hlob. Peb tau cog lus los ua kom tau raws li kev tswj hwm qhov kub thiab txias nrog peb cov dej chiller ntau yam:

CWFL series dej chillers muab ob chav ntsuas kub nrog kev xaiv ntawm qib precision: ± 0.5 ℃ thiab ± 1 ℃.

CW series dej chillers muaj kev tswj qhov kub thiab txias ntawm ± 0.3 ℃, ± 0.5 ℃, thiab ± 1 ℃.

CWUP thiab RMUP series dej chillers ua tau zoo nrog kev tswj xyuas qhov kub thiab txias txog li ± 0.1 ℃.

CWUL series dej chillers tam sim no kub tswj precision xaiv ntawm ± 0.2 ℃ thiab ± 0.3 ℃.

Raws li 3D tshuab luam ntawv tau txais kev saib xyuas thoob plaws hauv txoj kab nrog kev nce qib hauv zej zog, qhov xav tau rau kev tswj xyuas qhov kub thiab txias tau dhau los ua qhov tseem ceeb. Paub txog qhov kev thov no, cov neeg siv khoom ntseeg TEYU S&A dej chillers los muab kev txhawb nqa thiab kev tiv thaiv tsis sib xws rau lawv cov tshuab luam ntawv 3D.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.