Iinkqubo zokusebenza zomatshini wokukrola welaser kunye neCNC ziyafana. Ngelixa oomatshini bokukrola nge-laser ngobuchule luhlobo lomatshini wokukrola we-CNC, kukho umahluko omkhulu phakathi kwezi zibini. Ezona zintlukwano ziphambili yimigaqo yokusebenza, izinto zesakhiwo, ukusebenza kakuhle, ukuchaneka kokusetyenzwa, kunye neenkqubo zokupholisa.

Yintoni eyahlula umatshini wokukrola weLaser kumatshini wokukrola weCNC?

Iinkqubo zokusebenza zomatshini wokukrola we-laser kunye noomatshini bokukrola be-CNC ziyafana: okokuqala, yila ifayile yokukrola, emva koko ucwangcise ikhompyuter, kwaye ekugqibeleni, uqalise inkqubo yokukrola emva kokuba umyalelo ufunyenwe. Ngelixa oomatshini bokukrola nge-laser ngobuchule luhlobo lomatshini wokukrola we-CNC, kukho umahluko omkhulu phakathi kwezi zibini. Makhe sihlolisise umahluko:

1. Imigaqo yokuSebenza eyahluka-hlukeneyo

Oomatshini bokukrola beLaser basebenzisa amandla asuka kumqadi welaser ukuvelisa imichiza okanye ukusabela ngokwasemzimbeni kumphezulu wemathiriyeli ekroliweyo ukwenza ipateni efunekayo okanye umbhalo.

Oomatshini bokukrola be-CNC, kwelinye icala, bathembele ikakhulu kwintloko ekroliweyo ejikelezayo enesantya esiphezulu eqhutywa yintsimbi yombane elawula imela ekroliweyo kwaye ikhusele into eza kukrolwa ukusika iimilo zoncedo ezifunwayo kunye nesicatshulwa.

2. Iimpawu zeZakhiwo ezahlukileyo

Umthombo we-laser uhambisa i-laser beam, kwaye inkqubo ye-CNC ilawula i-motor stepper ukuhambisa ugxininiso kwi-X, Y, kunye ne-Z ye-axes yesixhobo somatshini ngezinto ezibonakalayo ezifana nentloko ye-laser, isibuko, kunye ne-lens ukutshisa kunye nokukrola izinto.

Isakhiwo somatshini wokukrola we-CNC silula. Ilawulwa yinkqubo yolawulo lwamanani ekhompyutheni ethi ikhethe ngokuzenzekelayo isixhobo sokukrola esifanelekileyo ukuze sikrolwe kwii-axes ze-X, Y, ne-Z zesixhobo somatshini.

Ngapha koko, isixhobo somatshini wokukrola we-laser siseti epheleleyo yamacandelo okukhanya, kanti isixhobo somatshini wokukrola we-CNC siqulunqwe ziintlobo ngeentlobo zezixhobo zokukrola eziqinileyo.

3. IiNdlela zokuSebenza eziDibeneyo

Umkrolo weLaser uyakhawuleza, unesantya esiphindwe kayi-2.5 kuneso koomatshini bokukrola beCNC. Oku kungenxa yokuba ukukrolwa kwelaser kunye nokupholisha kunokugqitywa kwinqanaba elinye, ngelixa ukukrolwa kweCNC kufuna amanyathelo amabini. Ukongeza, ukusetyenziswa kwamandla omatshini wokukrola we-laser kuphantsi kunomatshini wokukrola we-CNC.

4. Ukuchaneka koMsebenzi owahlukileyo

Ububanzi be-laser beam yi-0.01mm kuphela, ephindwe ngama-20 encinci kunesixhobo se-CNC, ngoko ke ukuchaneka kokulungiswa kwe-laser kuphezulu kakhulu kunomkrolo we-CNC.

5. IiNkqubo zokuPholisa ezahlukeneyo

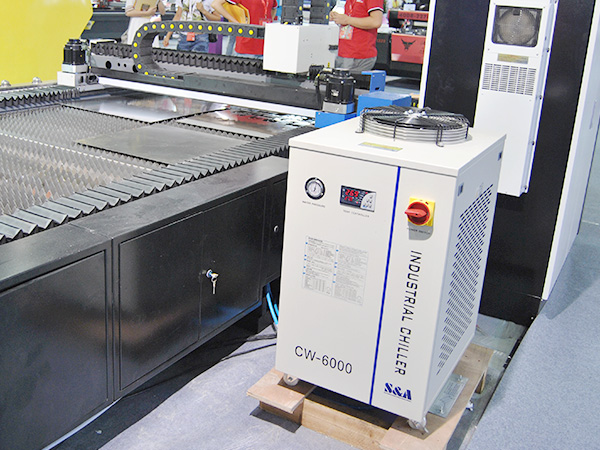

Oomatshini bokukrola beLaser bafuna ukuchaneka kokulawula ubushushu obuphezulu kunye ne-TEYU laser engraving chillers ezinika ulawulo oluchanekileyo lobushushu ukuya kuthi ga ku-±0.1℃ lunokusetyenziswa.

Oomatshini bokukrola be-CNC abafuni ukuchaneka kokulawula ubushushu obuphezulu kwaye banokusebenzisa i-CNC yokukrola ii-chillers ngokuchaneka kokulawula ubushushu obuphantsi (± 1℃), okanye abasebenzisi banokukhetha i-laser chillers ngokuchaneka okuphezulu kokulawula ubushushu.

6. Ezinye iiyantlukwano

Oomatshini bokukrola beLaser banengxolo ephantsi, abanangcoliso, kwaye bayasebenza, ngelixa oomatshini bokukrola beCNC benengxolo kwaye banokungcolisa okusingqongileyo.

I-Laser engraving yinkqubo engadibanisiyo engafuneki ukulungisa i-workpiece, ngelixa i-CNC ekrola yinkqubo yoqhagamshelwano efuna ukulungisa i-workpiece.

Oomatshini bokukrola beLaser banokwenza izinto ezithambileyo ezinje ngamalaphu, ufele, kunye neefilim, ngelixa oomatshini bokukrola beCNC banokusebenza kuphela izixhobo zokusebenza ezisisigxina.

Oomatshini bokukrola beLaser basebenza ngakumbi xa kukrolwa izinto ezingeyiyo eyentsimbi ebhityileyo kunye nezinye izinto ezineendawo eziphezulu zokunyibilika, kodwa zinokusetyenziselwa kuphela ukukrola okusicaba. Nangona ukubonakala koomatshini bokukrola be-CNC kuncinci, banokuvelisa iimveliso ezinobubanzi obuthathu njengezoncedo.

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.