Embonini yokukhiqiza izinto zikagesi, iSurface Mount Technology (SMT) ibalulekile. Izilawuli eziqinile zezinga lokushisa nomswakama, ezigcinwa izinto zokupholisa njengama-water chiller, ziqinisekisa ukusebenza kahle futhi zinqande amaphutha. I-SMT ithuthukisa ukusebenza, ukusebenza kahle, futhi yehlisa izindleko nomthelela kwezemvelo, okuhlala kuyisisekelo sentuthuko yesikhathi esizayo ekukhiqizeni izinto zikagesi.

I-Surface Mount Technology (SMT) kanye Nokusebenza Kwayo Ezindaweni Zokukhiqiza

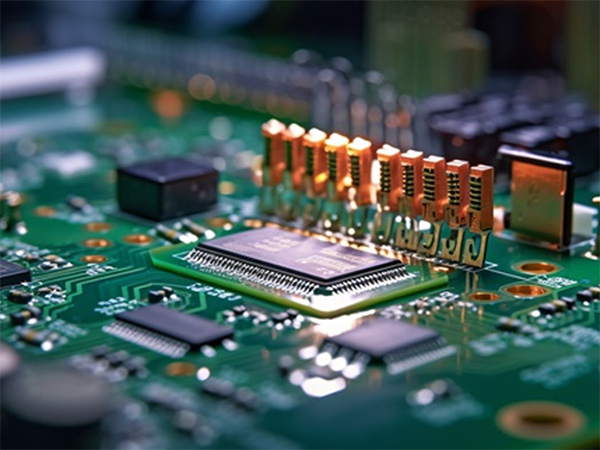

Embonini yanamuhla yokukhiqiza izinto zikagesi ezithuthuka ngokushesha, i-Surface Mount Technology (SMT) idlala indima ebalulekile. Ubuchwepheshe be-SMT bubandakanya ukubekwa okunembayo kwezingxenye ze-elekthronikhi kuma-Printed Circuit Boards (PCBs) okungagcinanga nje ngokuqhuba ukwenziwa kancane, ukulula, nokusebenza okuthuthukisiwe kwemikhiqizo ye-elekthronikhi, kodwa futhi okuthuthukise kakhulu ukuthembeka komkhiqizo nokusebenza kahle kokukhiqiza kuyilapho kunciphisa izindleko zokukhiqiza.

Inqubo Eyisisekelo Ye-SMT Surface Mounting

Inqubo yokufaka i-SMT surface mounting inembe futhi iyasebenza, iqukethe izinyathelo ezibalulekile ezimbalwa:

Ukuphrinta Kwe-Solder Paste: Ukusebenzisa ukunamathisela kwe-solder kumaphedi athile ku-PCB ukuze kulungiselelwe ukukhwezwa kwendawo okunembayo.

Ukukhweza Ingxenye: Kusetshenziswa isistimu yokukhweza yangaphezulu enembe kakhulu ukuze kumiswe izingxenye ze-elekthronikhi kumaphedi ananyathiselwe nge-solder.

I-Reflow Soldering: Ukuncibilikisa unamathisele we-solder kuhhavini ogeleza kabusha ngokujikeleza komoya oshisayo ukuze ubophe ngokuqinile izingxenye ze-elekthronikhi ku-PCB.

I-Automated Optical Inspection (AOI): Imishini ye-AOI ihlola ikhwalithi ye-PCB edayisiwe ukuze iqinisekise ukuthi azikho iziphambeko ezifana nezingxenye ezingalungile, izingxenye ezingekho, noma ukuhlehla.

Ukuhlolwa kwe-X-Ray: Kusetshenziswa okokusebenza kokuhlola i-X-ray ukuze kulawule izinga elijulile lezinga lamajoyinti e-solder afihliwe, njengalawo aku-Ball Grid Array (BGA) emaphaketheni.

Izidingo Zokulawula Izinga lokushisa Ezindaweni Zokukhiqiza

Imigqa yokukhiqiza ye-SMT inamazinga aqinile okushisa kanye nomswakama endaweni yokusebenza. Ukulawulwa kwezinga lokushisa kubalulekile ukuze kugcinwe ukuqina kwemishini kanye nekhwalithi yokusoda, ikakhulukazi ezindaweni ezinezinga lokushisa eliphezulu:

Ukulawulwa Kwezinga Lokushisa Kwezisetshenziswa: Imishini ye-SMT, ikakhulukazi amasistimu wokukhweza phezulu namahhavini agelezayo, akhiqiza ukushisa okukhulu ngesikhathi sokusebenza. Imishini yokupholisa efanele ivimbela ukushisa futhi iqinisekisa ukusebenza okuzinzile okuqhubekayo.

Izidingo Zenqubo Ekhethekile: Imishini yokupholisa isiza ukugcina imvelo edingekayo yezinga lokushisa eliphansi lezingxenye ezizwela ukushisa noma amasu athile okunamathisela.

Izinto zokupholisa ezifana nezishicileli zamanzi ezimbonini zibalulekile ukuze kugcinwe ukusebenza kahle kwemigqa yokukhiqiza, ukuvimbela ukonakala kokusoda noma ukuwohloka kokusebenza okubangelwa izinga lokushisa elidlulele.

Izinzuzo Zemvelo ze-SMT Surface Mounting

Ubuchwepheshe be-SMT bukhiqiza imfucuza encane phakathi nenqubo yokukhiqiza, okulula ukuyigaya kabusha nokuyilahla. Lokhu kwenza ubuchwepheshe bokucubungula i-SMT buhambisane nemvelo futhi busebenzise amandla. Ekugxileni kwanamuhla emhlabeni jikelele ekuvikelweni kwemvelo kanye nentuthuko esimeme, ubuchwepheshe be-SMT kancane kancane buba inqubo ethandwayo embonini yokukhiqiza izinto zikagesi.

Ubuchwepheshe be-SMT surface Mount bungamandla aqhuba ukuthuthuka kwemboni yokukhiqiza izinto zikagesi. Akugcini nje ngokuthuthukisa ukusebenza nokusebenza kahle kokukhiqizwa kwemikhiqizo kagesi kodwa futhi kunomthelela ekwehliseni izindleko zokukhiqiza kanye nokunciphisa umthelela wemvelo. Ngokuthuthuka kwezobuchwepheshe okuqhubekayo, ukunyuswa kwe-SMT kuzoqhubeka nokudlala indima ebalulekile esikhathini esizayo sokukhiqiza ngogesi.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.