Microchannel heat exchangers, with their high efficiency, compactness, lightweight design, and strong adaptability, are crucial heat exchange devices in modern industrial fields. Whether in aerospace, electronic information technology, refrigeration systems, or MEMS, microchannel heat exchangers demonstrate unique advantages and have a broad range of applications.

Application and Advantages of Microchannel Heat Exchanger in Industrial Chiller

With the rapid development of the industrial sector, industrial chillers have become increasingly essential cooling equipment across various industries. Recently, a highly efficient heat exchange technology known as the "microchannel heat exchanger" has garnered significant attention in the industrial world. So, what exactly is a microchannel heat exchanger, and what notable advantages does it offer in industrial chillers?

1. Understanding Microchannel Heat Exchangers

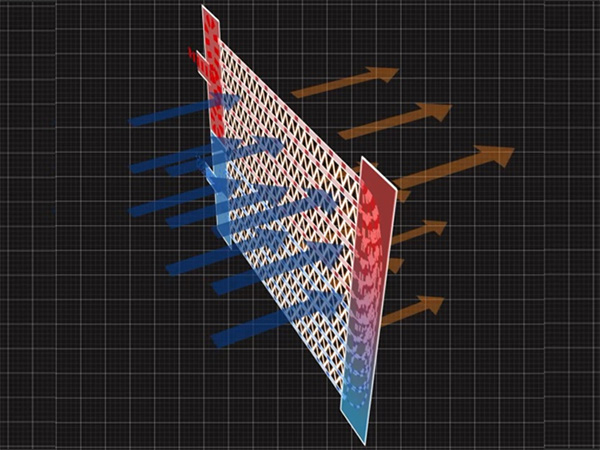

A microchannel heat exchanger is a type of heat exchange device that contains extremely small channels. These channels typically have hydraulic diameters ranging from 10 to 1000 micrometers, greatly expanding the heat exchange surface area and significantly enhancing heat transfer efficiency. Microchannel heat exchangers are used in various fields, including aerospace, electronic information technology, air conditioning, and micro-electromechanical systems (MEMS). Their high efficiency, pressure resistance, and compact design make them particularly advantageous. Research and applications have demonstrated their potential in improving overall cooling performance, especially when using high-performance cooling mediums like nanofluids.

The large heat exchange area of microchannel heat exchangers improves heat transfer efficiency and reduces airflow resistance. Additionally, their strong pressure resistance is attributed to the small channel diameters. In refrigeration systems, microchannel heat exchangers can serve as condensers or evaporators, offering superior heat exchange performance compared to traditional heat exchangers.

2. Advantages of TEYU S&A Industrial Chillers Using Microchannel Condensers

High Heat Transfer Efficiency: Microchannel heat exchangers use cleverly designed fins to create fluid turbulence, continuously disrupting the boundary layer and effectively increasing the heat transfer coefficient. Additionally, the thin design of the partitions and fins maximizes the thermal conductivity of the material. This combination results in exceptionally high heat transfer efficiency for microchannel heat exchangers.

Compact Structure: With an extended secondary surface area, the specific surface area of microchannel heat exchangers can reach up to 1000 square meters per cubic meter. This design significantly reduces space requirements and makes chiller systems more integrated and efficient, a critical advantage in space-constrained industrial environments.

Lightweight and Portable: The compact design and lightweight aluminum alloy materials make microchannel heat exchangers lighter than traditional heat exchangers. This not only simplifies installation and mobility but also reduces the overall weight of the industrial chiller, allowing TEYU S&A's industrial chillers to perform exceptionally well in various applications.

Strong Adaptability: The adaptability of microchannel heat exchangers is impressive, as they can easily handle gas-to-gas, gas-to-liquid, and liquid-to-liquid heat exchange, and even phase change heat exchange. Flexible flow channel arrangements and combinations enable them to adapt to counterflow, crossflow, multiple flows, and multiple-pass flow conditions. Furthermore, series, parallel, or series-parallel combinations between units allow them to meet the heat exchange needs of large equipment.

Microchannel heat exchangers, with their high efficiency, compactness, lightweight design, and strong adaptability, are crucial heat exchange devices in modern industrial fields. Whether in aerospace, electronic information technology, refrigeration systems, or MEMS, microchannel heat exchangers demonstrate unique advantages and have a broad range of applications.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.