As is known to all,laser cooling chiller has a high standard on the circulating water,so we often suggest clients to use purified water or clean distilled water.

As is known to all, laser cooling chiller has a high standard on the circulating water, so we often suggest clients to use purified water or clean distilled water. Howeve, as time goes by , there might be some impurities or ion in the circulating water, which will have a negative impact on the laser output of the laser machine. But this issue is often neglected by many chiller suppliers. As a reliable chiller supplier, we think of every need of our clients. Therefore, in order to absorb the impurities and ion in the waterway, some of our chiller models are equipped with 3 filters and one Greek client thought it was quite a thoughtful design.

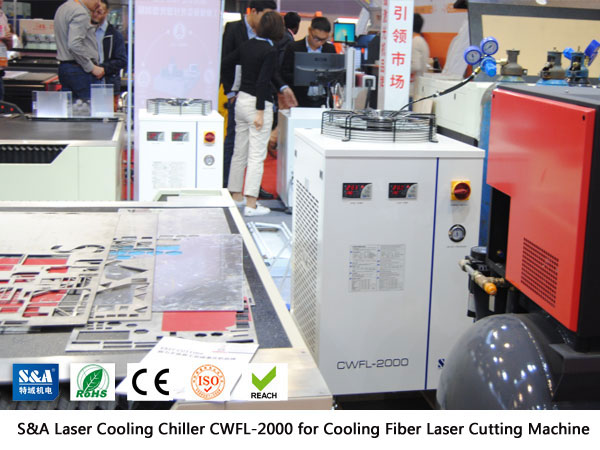

Mr. Lamprou from Greek runs a small metal plate cutting factory and he uses several fiber laser cutting machines in the production process. Lately he needed to purchase some new laser cooling chillers and he consulted us. He was so interested in our laser cooling chiller CWFL-2000. After our sales colleague explained to him about the technical details to him, he was quite impressed by the two wire wound filters and one de-ion filter of the chiller, for the previous chillers of other brands he used don’t have such filters. Well, we care what our client need.

Laser cooling chiller CWFL-2000 has high & low temperature control systems, which makes it capable of cooling the fiber laser and the optics/QBH connector at the same time. There are 3 filters on the laser cooling chiller CWFL-2000, including two wire wound filters for filtering the impurities in high & low temperaut waterways respectively and one de-ion filter for filtering the ion in the waterway, which helps maintain the stable output of the laser machine.