Recently we saw a piece of information on the Internet -- Is laser cutting machine used for cutting FPC the same as the one used for cutting stainless steel?

Recently we saw a piece of information on the Internet -- Is laser cutting machine used for cutting FPC the same as the one used for cutting stainless steel? Some laser machine manufacturers replied that they are the same. Other replied not. So what is the truth?

FPC laser cutting

FPC laser cutting can employ UV laser cutting machine as well as CO2 laser cutting machine. The difference between them is the processing effect. UV laser cutting machine adopts 355nm UV laser which is cold light source with shorter wavelength and smaller heat affect to the FPC. It features higher cutting precision without burr and carbonization. However, CO2 laser cutting machine adopts 10640nm CO2 laser which features big focal laser spot and bigger heat affect. Therefore, the FPC cut by CO2 laser cutting machine has higher level of carbonization. Therefore, it is obviously that UV laser cutting machine outperforms CO2 laser cutting machine in cutting FPC in terms of processing effect. But one thing should be kept in mind that UV laser cutting machine is more expensive than CO2 laser cutting machine.

Stainless steel laser cutting

In the current market, fiber laser cutting machine, YAG laser cutting machine and CO2 laser cutting machine can all be used to cut stainless steel. For cutting 0.1mm below stainless steel, people like to use UV laser cutting machine, CO2 laser cutting machine and fiber laser cutting machine. But again, UV laser cutting machine is a preferred tool because of its superior cutting effect but with high price. As for cutting 0.1mm+ stainless steel, people like to use fiber laser cutting machine and YAG laser cutting machine, for they have more power for penetration.

To sum up, both FPC laser cutting and stainless steel cutting have something in common - they both can use different processing techniques. What is different is the processing effect. Therefore, users should select the proper processing tool based on their own needs.

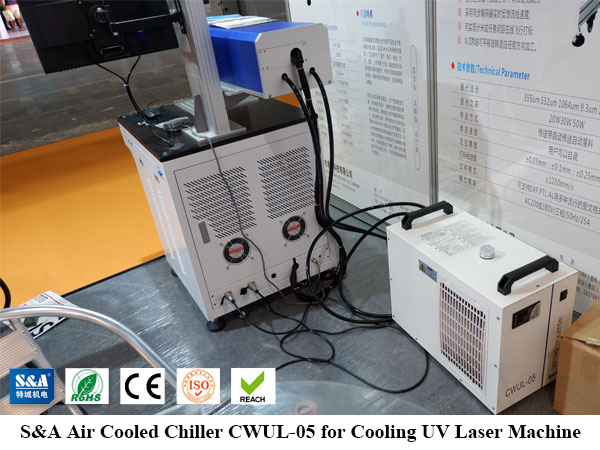

However, no matter what kinds of laser techniques are used, different laser sources are the key and also the heat generating components. To keep the laser sources cool, S&A Teyu develops reliable air cooled chillers tailored for different laser sources. We have CW series laser cooling chiller for CO2 laser, RMUP, CWUP and CWUL series recirculating water chiller for UV laser and RMFL & CWFL series industrial process chiller for fiber laser. Find out your desired chiller for your laser source at https://www.teyuchiller.com