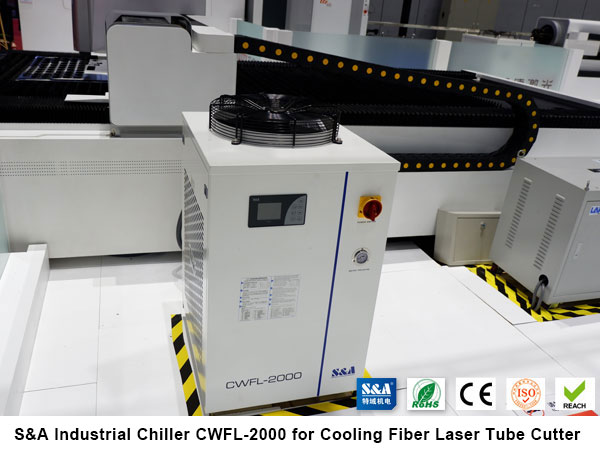

To maintain the high speed fiber laser tube cutter industrial chiller in a good condition, regular water changing is very necessary. It is very easy to change out the water if users follow the below steps.

1.Stop running the high speed fiber laser tube cutter and the industrial chiller;

2.Unscrew the drain cap of the industrial chiller in order to let out the original circulating water and then screw tight the cap;

3.Add the purified water or clean distilled water until it reaches the green area of the water level gauge.

After 18-year development, we establish rigorous product quality system and provide well-established after-sales service. We offer more than 90 standard water chiller models and 120 water chiller models for customization. With cooling capacity ranging from 0.6KW to 30KW, our water chillers are applicable to cool different laser sources,laser processing machines, CNC machines, medical instruments, laboratory equipment and so on.