Stable temperature control is critical for laser engraving quality. Even slight fluctuations can shift the laser focus, damage heat-sensitive materials, and accelerate equipment wear. Using a precision industrial laser chiller ensures consistent performance, higher accuracy, and longer machine life.

How Temperature Fluctuations in Laser Chiller Systems Affect Engraving Quality?

Precise temperature control plays a vital role in laser engraving, and the performance of the laser chiller directly impacts the stability and quality of the process. Even minor temperature fluctuations in the chiller system can significantly affect engraving results and equipment longevity.

1. Thermal Deformation Impacts Focus Accuracy

When the laser chiller's temperature fluctuates beyond ±0.5°C, the optical components inside the laser generator expand or contract due to thermal effects. Every 1°C deviation can cause the laser focus to shift by approximately 0.03 mm. This focus drift becomes especially problematic during high-precision engraving, leading to blurred or jagged edges and reduced overall engraving accuracy.

2. Increased Risk of Material Damage

Insufficient cooling causes more heat to be transferred from the engraving head to the material, by as much as 15% to 20%. This excess heat can result in scorching, carbonization, or deformation, particularly when working with heat-sensitive materials such as plastics, wood, or leather. Maintaining a stable water temperature ensures clean, consistent engraving results across a wide range of materials.

3. Accelerated Wear of Critical Components

Frequent temperature swings contribute to the accelerated aging of internal components, including optics, lasers, and electronic parts. This not only shortens equipment lifespan but also leads to higher maintenance costs and increased downtime, directly impacting production efficiency and operating costs.

Conclusion

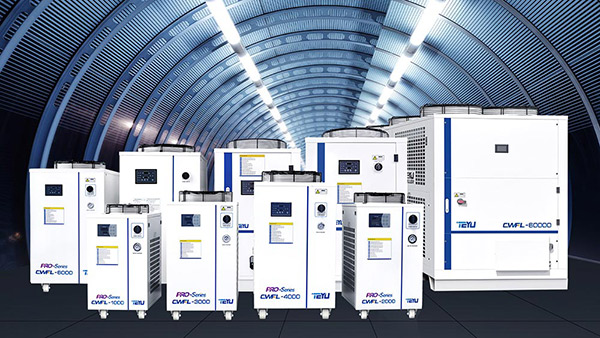

To ensure high engraving precision, material safety, and equipment durability, it is essential to equip laser engraving machines with industrial laser chillers capable of maintaining consistent water temperature. A reliable laser chiller with high temperature control accuracy—ideally within ±0.3°C—can effectively minimize risks and ensure long-term stable operation.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.