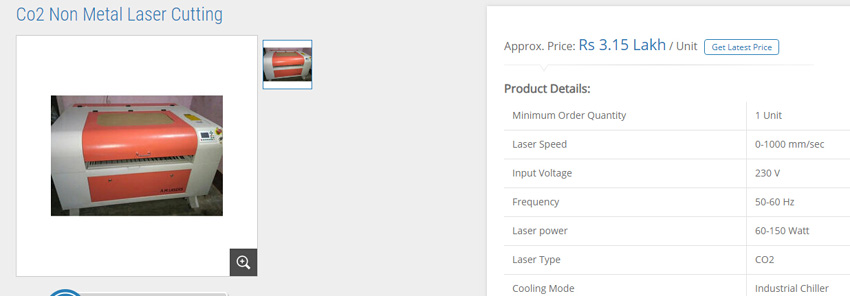

The parameter of Co2 Non Metal Laser Cutting in Uruguay as below:

Product Details:

Minimum Order Quantity 1 Unit

Laser Speed 0-1000 mm/sec

Input Voltage 230 V

Frequency 50-60 Hz

Laser power 60-150 Watt

Laser Type CO2

Cooling Mode Industrial Chiller

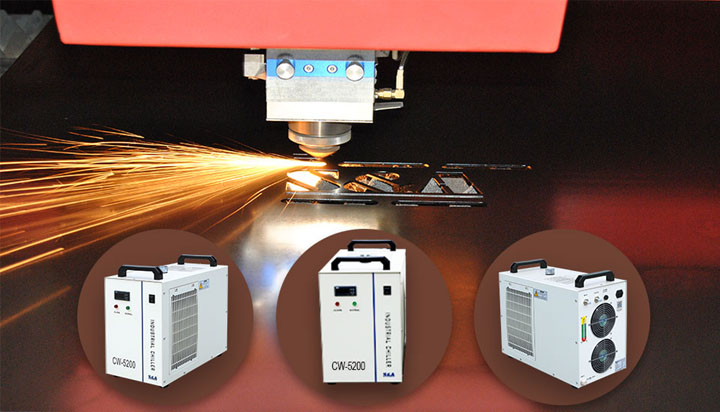

Cooling 60-150watt Co2 Non Metal Laser Cutting machine, recommnend S&A Teyu chiller CW-5000 and CW-5200.

CW-5000 details: https://www.chillermanual.net/80w-co2-laser-chillers-800w-cooling-capacity-220v100v-50hz60hz_p27.html

CW-5200 details: https://www.chillermanual.net/130w-co2-laser-tube-water-chillers_p31.html

CONTOUR AND PARTS INTRODUCTION

Independent production of sheet metal,evaporator and condenser

High precision temperature control system

Adopt IPG fiber laser for welding and cutting sheet metal. Temperature control accuracy can reach ±0.3°C.

Ease of moving and water filling

The firm handle can help move the water chillers easily.

Inlet and outlet connector equipped. Multiple alarm protection.

The laser will stop working once it receives alarm signal from the water chiller for protection purpose.

Cooling fan of famous brand installed.

Level gauge equipped.

Adopt SAN JU cooling fan with high quality and low failure rate.

Customized dust gauze available and easy to take apart.

Identify Teyu(S&A Teyu) authentic chiller

All of S&A Teyu water chillers are certified with design patent. Counterfeiting is not allowed.

Please recognize S&A Teyu logo when you purchase S&A Teyu water chillers.

Components carry “S&A Teyu” brand logo. It is an important identification distinguishing from counterfeit machine.

More than 3,000 manufacturers choosing Teyu (S&A Teyu)

The reasons of quality guarantee of Teyu (S&A Teyu) chiller

Compressor in Teyu chiller: adopt compressors from Toshiba, Hitachi, Panasonic and LG etc well-known joint venture brands.

Independent production of evaporator: adopt standard injection molded evaporator to minimize risks of water and refrigerant leakage and improve quality.

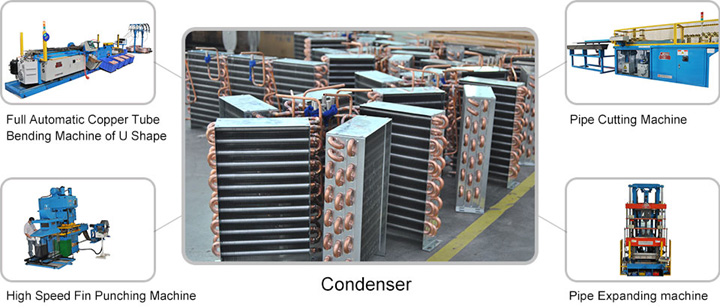

Independent production of condenser: condenser is the center hub of industrial chiller. Teyu invested millions in condenser production facilities for the sake of strictly monitoring production process of fin, pipe bending and welding etc to ensure the quality.Condenser production facilities: High Speed Fin Punching Machine, Full Automatic Copper Tube Bending Machine of U Shape, Pipe Expanding Machine, Pipe Cutting Machine.

Independent production of Chiller sheet metal: manufactured by IPG fiber laser cutting machine and welding manipulator. Higher than higher quality is always the aspiration of S&A Teyu