Novel two-photon polymerization technique not only reduces the cost of femtosecond laser 3D printing but also maintains its high-resolution capabilities. Since the new technique can be easily integrated into existing femtosecond laser 3D printing systems, it is likely to accelerate its adoption and expansion across industries.

New Breakthrough in Femtosecond Laser 3D Printing: Dual Lasers Lower Costs

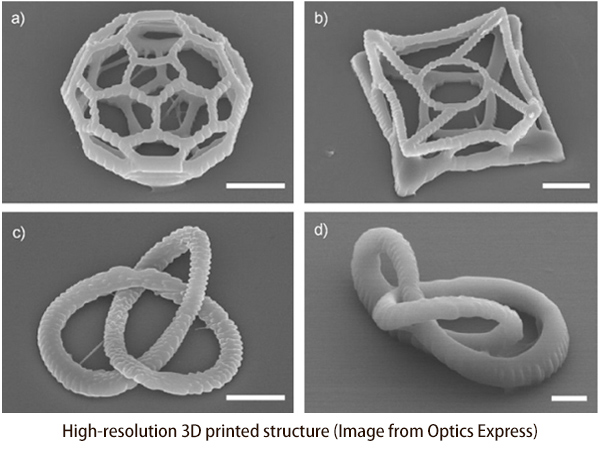

Scientists at Purdue University have recently made a significant breakthrough in femtosecond laser 3D printing technology. They developed a novel two-photon polymerization technique that ingeniously combines two lasers for 3D printing. By doing so, they managed to print intricate, high-resolution 3D structures while reducing femtosecond laser power by 50%. This innovation not only promises to significantly reduce the cost of high-resolution 3D printing but also expands the potential applications of this technology across various fields.

Specifically, the research team combined a relatively low-cost visible light laser with an infrared pulsed femtosecond laser, greatly reducing the required femtosecond laser power. To optimize the balance between the two lasers, they developed a new mathematical model to better understand the photochemical processes and precisely calculate the synergistic effects of two-photon and single-photon excitation. Experimental results showed that for 2D structures, this method reduced the required femtosecond laser power by 80%, and for 3D structures, by about 50%.

Overall, this new technique not only reduces the cost of femtosecond laser 3D printing but also maintains its high-resolution capabilities. This groundbreaking development is expected to spur new applications in fields such as biomedicine, micro-robotics, and micro-optical devices. Moreover, since the new technique can be easily integrated into existing femtosecond laser 3D printing systems, it is likely to accelerate its adoption and expansion across industries.

As a leading chiller manufacturer with 22 years of experience in industrial and laser cooling, TEYU S&A Chiller continuously tracks advancements in laser technology and expands our chiller product lines to meet evolving cooling needs. If you're looking for a reliable laser chiller, feel free to contact us via sales@teyuchiller.com.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.