Njira zogwirira ntchito pamakina onse a laser chosema ndi CNC ndizofanana. Ngakhale makina laser chosema mwaukadaulo mtundu wa CNC chosema makina, pali kusiyana kwakukulu pakati pa awiriwo. Kusiyanitsa kwakukulu ndi mfundo zoyendetsera ntchito, zinthu zamapangidwe, magwiridwe antchito, kuwongolera bwino, ndi machitidwe ozizira.

Kodi Chimasiyanitsa Makina Ojambula a Laser ndi Makina Ojambula a CNC?

Njira zogwirira ntchito zamakina onse a laser chosema ndi CNC ndizofanana: choyamba, pangani fayilo yojambulira, kenaka yambitsani kompyuta, ndipo pomaliza, yambitsani zojambulajambula mukalandira lamulo. Ngakhale makina laser chosema mwaukadaulo mtundu wa CNC chosema makina, pali kusiyana kwakukulu pakati pa awiriwo. Tiyeni tione kusiyanitsa:

1. Mfundo Zoyendetsera Ntchito Zosiyana

Makina ojambulira a laser amagwiritsa ntchito mphamvu kuchokera ku mtengo wa laser kuti apange mankhwala kapena zochitika zakuthupi pamwamba pa zinthu zomwe zalembedwa kuti apange mtundu womwe mukufuna kapena zolemba.

Komano makina ojambulira a CNC, amadalira makamaka pamutu wozokota wothamanga kwambiri womwe umayendetsedwa ndi chopota chamagetsi chomwe chimawongolera mpeni wozokota ndikuteteza chinthucho kuti chilembedwe kuti chidule mawonekedwe ofunikira ndi zolemba.

2. Zinthu Zapangidwe Zosiyana

Gwero la laser limatumiza mtengo wa laser, ndipo makina a CNC amawongolera mota ya stepper kuti isunthire kuyang'ana pa X, Y, ndi Z nkhwangwa zamakina kudzera pa zinthu zowoneka bwino monga mutu wa laser, kalilole, ndi mandala kuti awotche ndikulemba zinthuzo.

Mapangidwe a makina a CNC ndi osavuta. Imayendetsedwa ndi makina owongolera manambala apakompyuta omwe amasankha okha chida choyenera chozokota kuti alembe pa nkhwangwa za X, Y, ndi Z za chida cha makina.

Komanso, chida laser chosema makina ndi seti wathunthu wa zigawo kuwala, pamene CNC chosema chida makina wapangidwa zosiyanasiyana zida zolimba chosema.

3. Osiyana Processing Mwachangu

Laser chosema mofulumira, ndi liwiro 2.5 nthawi wamkulu kuposa makina CNC chosema. Izi ndichifukwa choti kujambula ndi kupukuta kwa laser kumatha kumalizidwa mu gawo limodzi, pomwe kujambula kwa CNC kumafuna masitepe awiri. Komanso, mowa mphamvu ya makina laser chosema ndi wotsika kuposa makina CNC chosema.

4. Zosiyanasiyana Processing Precision

Kutalika kwa mtengo wa laser ndi 0.01mm yokha, yomwe ndi yaying'ono nthawi 20 kuposa chida cha CNC, kotero kulondola kwa makina a laser ndikokwera kwambiri kuposa kujambula kwa CNC.

5. Njira Zozizira Zosiyanasiyana

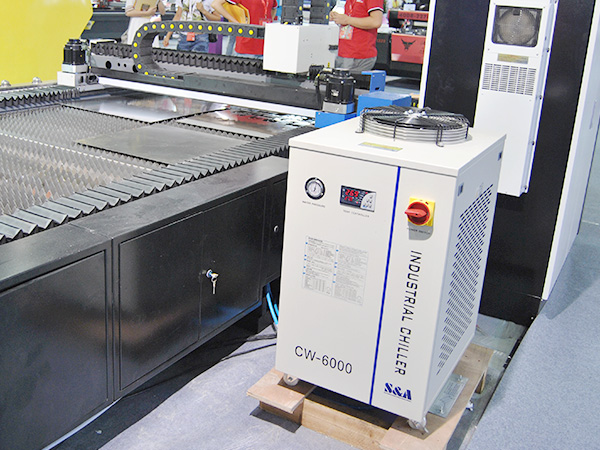

Makina ojambulira laser amafunikira kuwongolera kutentha kwapamwamba kwambiri ndipo zoziziritsa kukhosi za TEYU laser zomwe zimapereka kuwongolera kolondola kwa kutentha mpaka ± 0.1 ℃ angagwiritsidwe ntchito.

CNC chosema makina safuna mkulu kutentha kulamulira mwatsatanetsatane ndipo angagwiritse ntchito CNC chosema chillers ndi mwatsatanetsatane kutentha kulamulira (± 1 ℃), kapena owerenga akhoza kusankha chillers laser ndi apamwamba kulamulira kutentha mwatsatanetsatane.

6. Kusiyana kwina

Makina ojambulira a laser amakhala opanda phokoso, alibe kuipitsa, komanso amagwira ntchito bwino, pomwe makina ojambulira a CNC amakhala aphokoso ndipo amatha kuipitsa chilengedwe.

Laser chosema ndi njira sanali kukhudzana kuti sikutanthauza kukonza workpiece, pamene CNC chosema ndi njira kukhudzana kuti amafuna kukonza workpiece.

Makina ojambulira a laser amatha kukonza zinthu zofewa monga nsalu, zikopa, mafilimu, pomwe makina ojambulira a CNC amatha kukonza zida zokhazikika.

Laser chosema makina ndi aluso kwambiri pamene chosema sanali zitsulo zitsulo woonda ndi zipangizo zina ndi mfundo kusungunuka mkulu, koma angagwiritsidwe ntchito lathyathyathya chosema. Ngakhale maonekedwe a CNC chosema makina penapake ochepa, iwo akhoza kupanga mankhwala a mbali zitatu monga reliefs.

Tabwera chifukwa cha inu mukadzatifuna.

Chonde lembani fomu yolumikizana nafe, ndipo tidzakhala okondwa kukuthandizani.