Recirculating Closed Loop Water Chiller Unit for Metal Plate Fiber Laser Cutting Machine

Product Description

To maintain the cutting accuracy and efficiency of metal plate fiber laser cutting machine, equipping with recirculating closed loop water chiller unit is quite essential. If your fiber laser source of the metal plate fiber laser cutting machine is 1500W, then recirculating closed loop water chiller unit CWFL-1500 might be your ideal choice.

The CWFL series water chillers are so multi-functional that the laser device and the QBH connector/optics can be cooled by the low temperature control system and the high temperature control system respectively at the same time, which can greatly reduce the generation of the condensed water and save cost & space.

1. With environmental refrigerant;

2. ±0.5℃ precisely temperature control;

3. The intelligent temperature controller has 2 control modes, applicable to different applied occasions; with various setting and display functions;

4. Dual temperature to satisfy different needs of fiber laser device and the optics;

5. With Ion adsorption filtrating and test functions conform to fiber laser device operating requirements;

6. Multiple alarm functions: compressor time-delay protection, compressor overcurrent protection, water flow alarm and over high / low temperature alarm;

7. Multiple power specifications; CE approval; RoHS approval; REACH approval;

8. Optional heater and water filter.

THE WARRANTY IS 2 YEARS AND THE PRODUCT IS UNDERWRITTEN BY INSURANCE COMPANY.

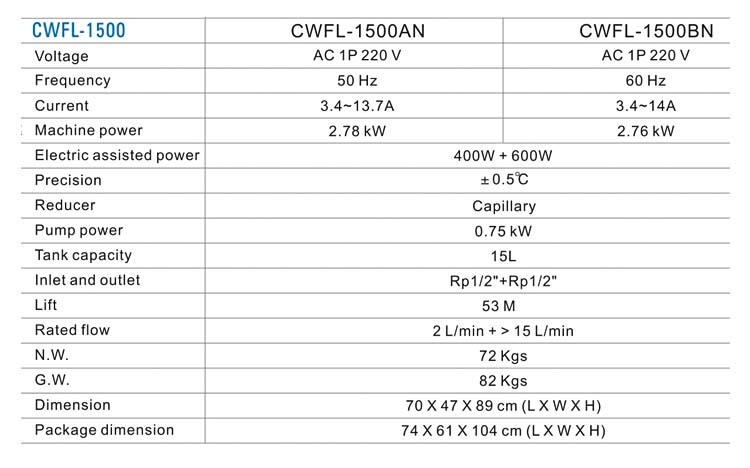

Industrial water chillers for fiber lasers specification

Note: the working current can be different under different working conditions; The above information is for reference only. Please subject to the actual delivered product.

PRODUCT INTRODUCTION

Independent production of sheet metal, evaporator and condenser

Adopt IPG fiber laser for welding and cutting sheet metal.

Temperature control accuracy can reach ±0.5℃. High temp. for QBH connector/optics and low temp. for laser device.

Multiple alarm protection

Equipped with water pressure gauges ,drain outlet with valve and universal wheels.

Dual inlet and dual outlet connector equipped.

Chiller inlet connects to laser outlet connector. Chiller outlet connects to laser inlet connector.

Level gauge equipped

Cooling fan of famous brand installed.

Customized dust gauze available and easy to take apart

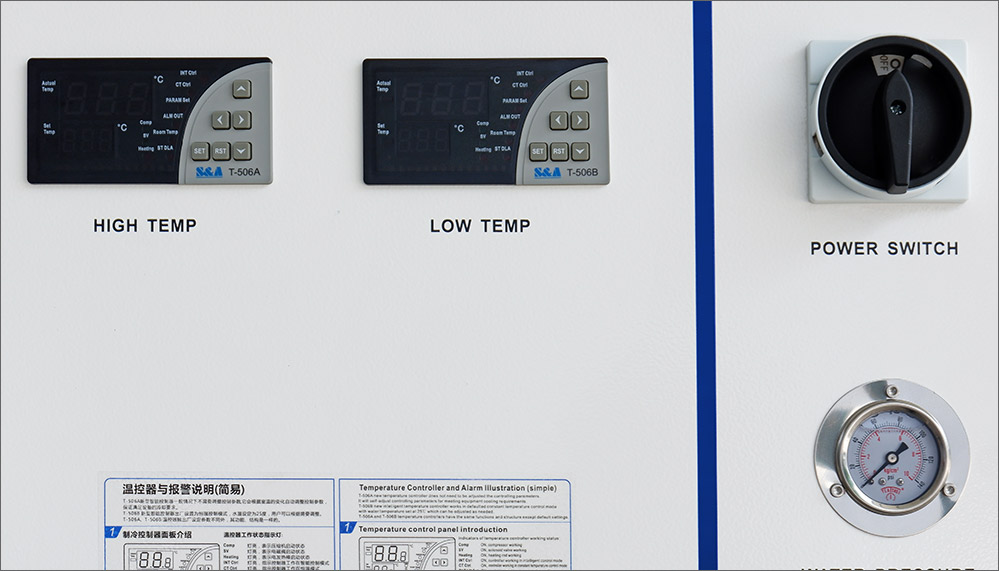

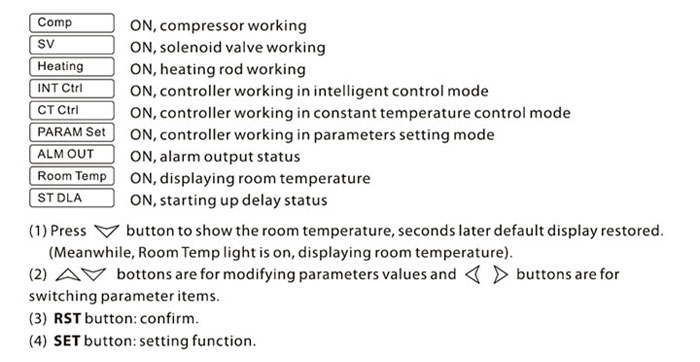

TEMPERATURE CONTROLLER PANEL DESCRIPTION

S&A Teyu industrial water chillers are popular for its 2 temperature control modes as constant temperature and intelligent temperature control.Generally speaking, the defaulted setting for the temperature controller is intelligent temperature control mode. Under intelligent temperature control mode, the water temperature will adjust itself according to the ambient temperature. However, under constant temperature control mode, users can adjust the water temperature manually.

Temperature controller panel description:

Alarm function

E2 - ultrahigh water temperature

E3 - ultralow water temperature

E4 - room temperature sensor failure

E5 - water temperature sensor failure

E6 - external alarm input

E7 - water flow alarm input

WAREHOUSE

Video

S&A Teyu Temperature Controlled Refrigerating ChillerCWFL-1500 video

How to adjust the water temperature for T-506 intelligent mode of chiller

S&A Teyu recirculation water chiller CWFL-1500 for cooling 1500W metal fiber laser cutter

S&A Teyu water chiller CWFL-1500 for Raycus fiber laser welding machine

CHILLER APPLICATION

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.