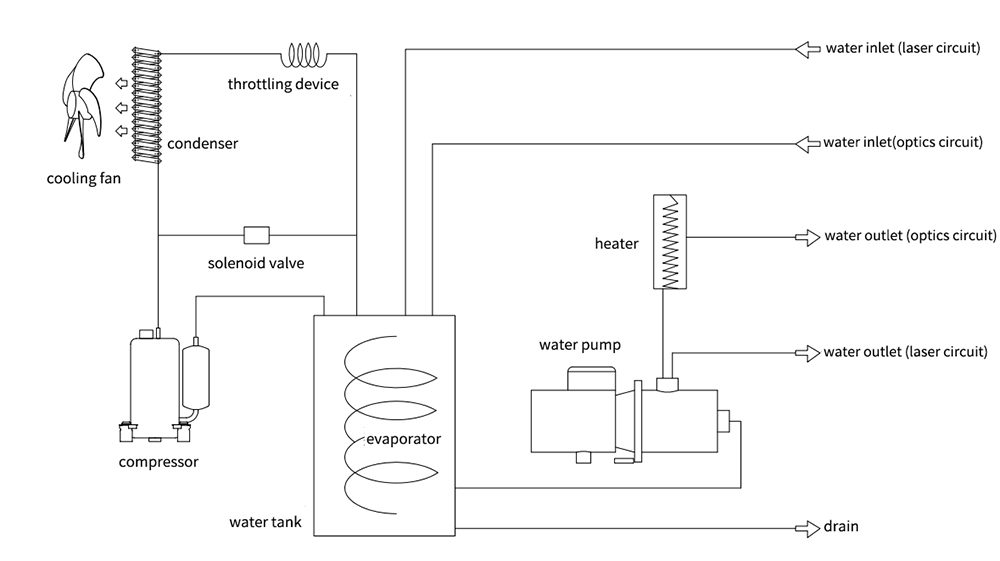

Heater

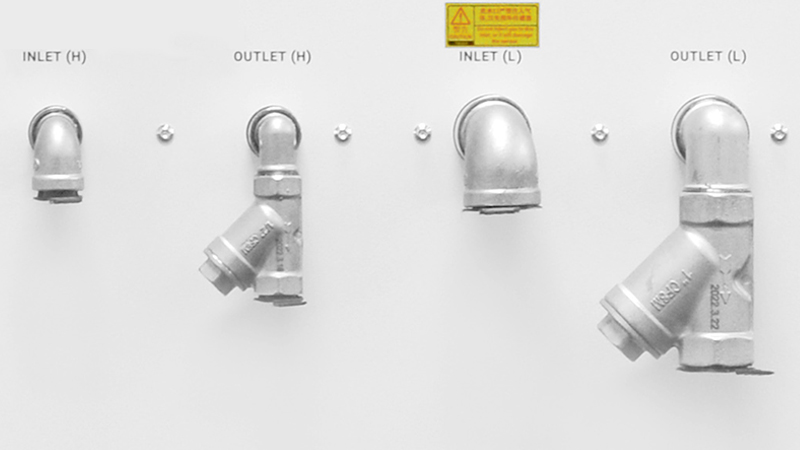

Filter

Recirculating water chiller system CWFL-3000 is able to regulate and maintain the temperature of two parts of a laser processing machine - -the 3kW fiber laser and the optics, thanks to the dual temperature control circuit inside the chiller. Both the refrigeration circuit and the water temperature are controlled by the intelligent digital control panel. CWFL-3000 water chiller is equipped with high performance water pump which guarantees that water circulation between the chiller and the above-mentioned two heat-producing parts can be ongoing. Being Modbus-485 capable, this laser chiller can realize the communicate with the laser system. Available in SGS-certified version, equivalent to UL standard.

Model: CWFL-3000

Machine Size: 77X55X103cm (L X W X H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CWFL-3000ANP | CWFL-3000BNP | CWFL-3000ENP |

| Voltage | AC 1P 220-240V | AC 1P 220-240V | AC 3P 380V |

| Frequency | 50Hz | 60Hz | 50Hz |

| Current | 6.2~35.3A | 3.6~31.7A | 2.1~15A |

|

Max. power consumption |

6.51kW | 6.49kW | 6.42kW |

|

Heater power |

1kW+1.4kW | ||

| Precision | ±0.5℃ | ||

| Reducer | Capillary | ||

| Pump power | 1.1kW | 1kW | 1.1kW |

| Tank capacity | 22L | ||

| Inlet and outlet | Rp1/2"+Rp1" | ||

|

Max. pump pressure |

6.15 bar | 5.9 bar | 6.15 bar |

| Rated flow | 2L/min+>30L/min | ||

| N.W. | 99kg | 94kg | 105kg |

| G.W. | 116kg | 111kg | 122kg |

| Dimension | 77X55X103cm (L X W X H) | ||

| Package dimension | 78X65X117cm (L X W X H) | ||

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Dual cooling circuit

* Active cooling

* Temperature stability: ±0.5°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410A/R-32

* Intelligent digital control panel

* Integrated alarm functions

* Back mounted fill port and easy-to-read water level check

* RS-485 Modbus communication function

* High reliability, energy efficiency and durability

* Available in 380V or 220V

* Available in SGS-certified version, equivalent to UL standard.

Dual temperature control

The intelligent control panel offers two independent temperature control systems. One is for controlling the temperature of the fiber laser and the other is for controlling the temperature of the optics.

Dual water inlet and water outlet

Water inlets and water outlets are made from stainless steel to prevent potential corrosion or water leakage.

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.