After prolonged use, industrial chillers tend to accumulate dust and impurities, impacting their heat dissipation performance and operational efficiency. Therefore, regular cleaning of industrial chiller units is essential. The main cleaning methods for industrial chillers are dust filter and condenser cleaning, water system pipeline cleaning, and filter element and filter screen cleaning. Regular cleaning helps maintain the optimal operational state of the industrial chiller and effectively extends its lifespan.

Regular Cleaning and Maintenance Methods for Industrial Chiller Units

After prolonged use, industrial chillers tend to accumulate dust and impurities, impacting their heat dissipation performance and operational efficiency. Therefore, regular cleaning of industrial chiller units is essential. Let's explore several cleaning methods for industrial chillers:

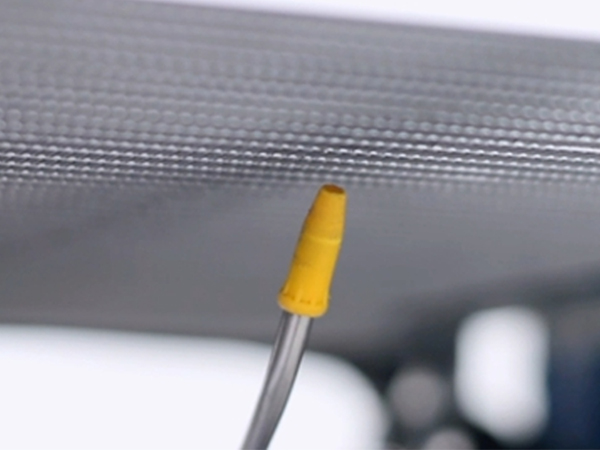

Dust Filter and Condenser Cleaning:

Periodically clean the dust and impurities on the surface of the dust filter and condenser of industrial chillers using an air gun.

*Note: Maintain a safe distance (approximately 15cm) between the air gun outlet and the condenser radiator. The air gun outlet should blow vertically toward the condenser.

Water System Pipeline Cleaning:

It is recommended to use distilled water or pure water as the medium for industrial chillers, with regular replacements to reduce the formation of scale. If excessive scale accumulates in the industrial chiller, it can trigger flow alarms and affect the efficiency of the industrial chiller. In such cases, cleaning the circulating water pipes is necessary. You can mix a cleaning agent with water, soak the pipes in the mixture for a period, and then rinse the pipes repeatedly with clean water once the scale has softened.

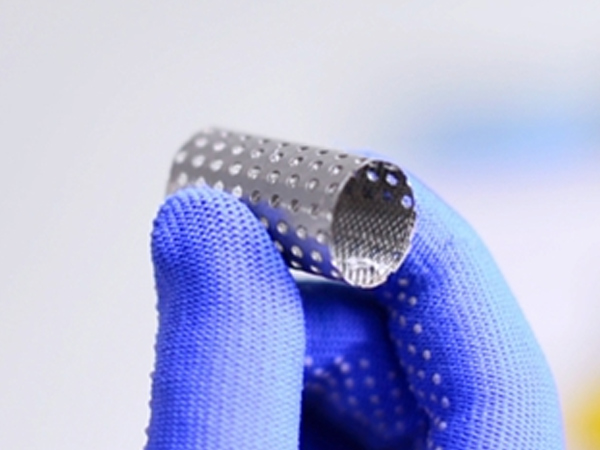

Cleaning the Filter Element and Filter Screen:

The filter element/filter screen is the most common area for collecting impurities, and it requires regular cleaning. If the filter element/filter screen is too dirty, it should be replaced to ensure a stable water flow in the industrial chiller.

Regular cleaning helps maintain the optimal operational state of the industrial chiller and effectively extends its lifespan. Please ensure that the power is turned off before conducting any cleaning operations to ensure the personal safety of operators. For more information on the maintenance of industrial chiller units, feel free to email service@teyuchiller.com to consult TEYU's professional service team!

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.