Small Water Chiller CW3000 for CNC Engraving Machine Spindle

Product Description

Industrial water chiller CW-3000 is a heat-dissipating type water cooler instead of refrigeration type. It features the radiating capacity of 50W/℃ which means that when the water temperature increases 1℃, there will be 50W heat taken away from the equipment to be cooled. Therefore, it is very suitable for cooling equipment which has small heat load, such as CNC engraving and cutting machine spindle.

Being the only type of heat-dissipating type water cooler, industrial water cooler CW-3000 becomes the ideal standard accessory for CNC machine users with its ease of use, long service life, low noise level and ease of moving.

In terms of the circulating water of small water chiller CW-3000, it is recommended to use clean distilled water or purified water, for these two types of water can avoid the potential clogging inside the waterway, which helps extend the working life of the water chiller itself.

Users can rest assured using industrial water cooler CW-3000, for there will be 2 years warranty on this chiller.

Features

1. Radiating capacity: 50W / °C;

2. Small thermolysis water chiller, energy saving, long working life and simple operation;

3. With completed water flow and over high temperature alarm functions;4. Multiple power specifications; CE ,RoHS and REACH approval.

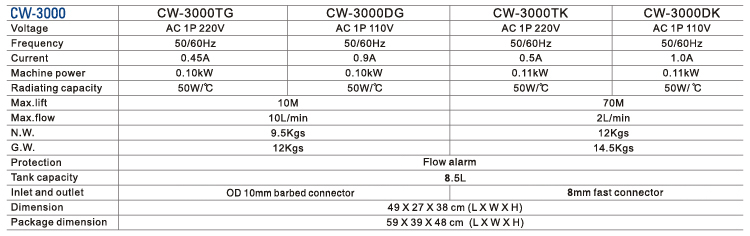

Specification

CW-3000: applied to cool CO2 laser tubeCW-3000: applied to cool CNC spindles or welding equipment;

Note: the working current can be different under different working conditions; The above information is for reference only. Please subject to the actual delivered product.

PRODUCT INTRODUCTION

Independent production of sheet metal and heat exchanger. Fast cooling.

Ease of moving and water filling.

Inlet and outlet connector equipped. Multiple alarm protection.

High speed fan of famous brand installed.

Easy water draining

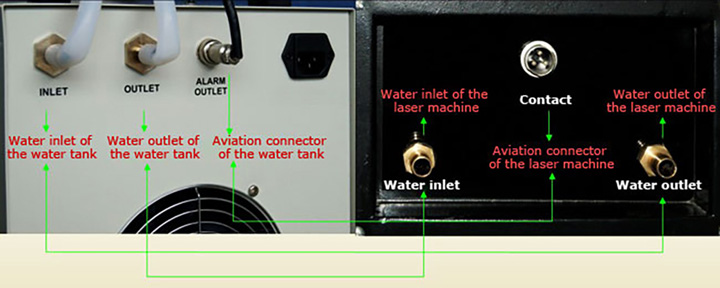

Connection diagram between water chiller and laser machine

Water outlet of the water tank connects to water inlet of the laser machine while water inlet of the water tank connects to water outlet of the laser machine. Aviation connector of the water tank connects to the aviation connector of the laser machine.

Alarm description

E0 - water flow alarm input

E1 - ultrahigh water temperature

HH - short circuit of water temperature sensor

LL - water temperature sensor open circuit

MAINTENANCE

1. To ensure good heat dissipating, please open the lid to clean the dirt after the chiller is used in long-term.

2. Users in cold area should use noncorrosive antifreeze fluid

Method of exchanging water in the water tank

Drain the waste water out of the water tank through the drain outlet and fill the clean water into the tank through the filling hole.

The circulating water should be exchanged every 3 months. The quality of the circulating water will directly influence the service life of the laser tube.It is recommended to use purified water or clean distilled water.

All of S&A Teyu water chillers are certified with design patent. Counterfeiting is not allowed.

The reasons of quality guarantee of S&A Teyu chiller

Compressor in Teyu chiller: adopt compressors from Toshiba, Hitachi, Panasonic and LG etc well-known joint venture brands.

Independent production of evaporator: adopt standard injection molded evaporator to minimize risks of water and refrigerant leakage and improve quality.

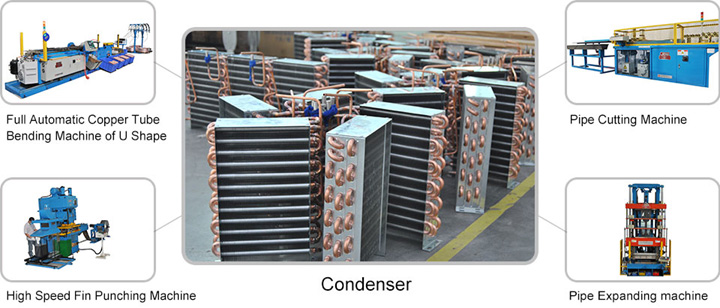

Independent production of condenser: condenser is the center hub of industrial chiller. Teyu invested millions in condenser production facilities for the sake of strictly monitoring production process of fin, pipe bending and welding etc to ensure the quality.Condenser production facilities: High Speed Fin Punching Machine, Full Automatic Copper Tube Bending Machine of U Shape, Pipe Expanding Machine, Pipe Cutting Machine.

Independent production of Chiller sheet metal: manufactured by IPG fiber laser cutting machine and welding manipulator. Higher than higher quality is always the aspiration of S&A Teyu

Video

S&A Teyu water chillers CW-3000

S&A Teyu chiller CW-3000 for acrylic machine

S&A Teyu water chiller cw3000 for AD engraving cutting machine

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.