Maitiro ekushanda eese ari maviri laser engraving uye CNC ekunyora michina akafanana. Nepo laser engraving michina iri tekinoroji mhando yemuchina weCNC wekunyora, pane misiyano yakakura pakati pezviviri izvi. Misiyano mikuru ndeye misimboti yekushanda, zvimiro zvechimiro, mashandiro ekugadzirisa, kunyatsogadzirisa, uye kutonhora masisitimu.

Chii chinosiyanisa Laser Engraving Machine kubva CNC Engraving Machine?

Maitiro ekushanda eese ari maviri laser engraving uye CNC ekunyora michina akafanana: kutanga, gadzira faira rekunyora, wozoronga komputa, uye pakupedzisira, tanga maitiro ekunyora kana murairo wagamuchirwa. Nepo laser engraving michina iri tekinoroji mhando yemuchina weCNC wekunyora, pane misiyano yakakura pakati pezviviri izvi. Ngationgororei misiyano:

1. Divergent Operating Principles

Laser engraving michina inoshandisa simba kubva kune laser beam kugadzira kemikari kana kuita kwemuviri pamusoro pechinhu chiri kunyorwa kugadzira iyo inodiwa pateni kana zvinyorwa.

Michina yekunyora yeCNC, kune rumwe rutivi, inovimba zvakanyanya nemusoro wepamusoro-soro unotenderera unotemerwa unofambiswa nemagetsi anorukwa anodzora banga rekunyora uye anochengetedza chinhu chinofanira kunyorwa kuti chicheke maumbirwo anodiwa uye zvinyorwa.

2. Distinctive Structural Elements

Iyo laser sosi inofambisa danda relaser, uye iyo CNC system inogadzirisa mota inotsika kuti ifambise kutarisa paX, Y, uye Z axes yemuchina wemuchina kuburikidza nezvinhu zvemaziso zvakaita semusoro welaser, girazi, uye lens kupisa uye kunyora zvinyorwa.

Chimiro chemuchina weCNC chiri nyore. Inodzorwa nekombuta yenhamba yekudzora sisitimu iyo inosarudza otomatiki chishandiso chakakodzera chekunyora paX, Y, uye Z maaxes emuchina chishandiso.

Uye zvakare, iyo laser engraving muchina chishandiso izere seti yezvinhu zvemaziso, nepo CNC yekuchera muchina chishandiso chinoumbwa neakasiyana akasimba ekunyora maturusi.

3. Distinct Processing Efficiencies

Laser nokuveza inokurumidza, ane 2.5 nguva mukuru kumhanya pane kuti CNC nokuveza michina. Izvi zvinokonzerwa nekuti laser engraving uye polishing inogona kupedzwa munhanho imwe chete, nepo CNC kunyora kunoda matanho maviri. Pamusoro pezvo, kushandiswa kwesimba kwelaser engraving muchina kwakadzikira pane iyo yemuchina weCNC wekunyora.

4. Different Processing Precision

Iyo dhayamita yelaser beam ingori 0.01mm, inova idiki zvakapetwa makumi maviri pane CNC chishandiso, saka iko kurongeka kwelaser engraving kwakakwira zvakanyanya kupfuura iyo yeCNC engraving.

5. Different Cooling Systems

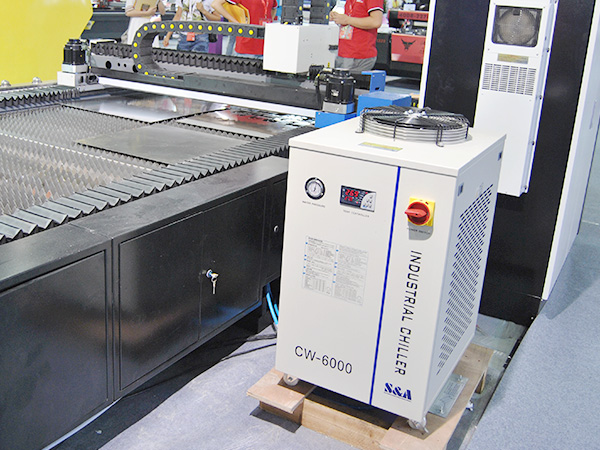

Laser engraving michina inoda yakakwirira tembiricha yekudzora kurongeka uye TEYU laser engraving chillers inopa chaiyo tembiricha yekudzora inosvika ± 0.1 ℃ inogona kushandiswa.

CNC yekutemera michina haidi yakakwira tembiricha yekudzora kurongeka uye inogona kushandisa CNC yekuchera chiller ine yakaderera tembiricha kutonga chaiko (± 1 ℃), kana vashandisi vanogona kusarudza laser chiller ine yakakwirira tembiricha kutonga nemazvo.

6. Zvimwe Zvakasiyana

Laser engraving michina yakaderera-ruzha, kusvibiswa-isina, uye inoshanda, nepo CNC yekunyora michina ine ruzha uye inogona kusvibisa nharaunda.

Laser engraving inzira isiri-yekubata iyo isingade kugadzirisa iyo workpiece, nepo CNC engraving inzira yekusangana inoda kugadzirisa iyo workpiece.

Laser engraving michina inogona kugadzira zvinyoro zvinyoro senge machira, matehwe, uye mafirimu, nepo CNC yekutemera michina inogona kungogadzira yakagadziriswa workpieces.

Laser nokuveza michina anonyanya kushanda kana nokutemera asiri-metallic nhete zvinhu uye zvimwe zvinhu ane yakakwirira kunyunguduka pfungwa, asi anogona chete kushandiswa sandara nokuveza. Kunyangwe kutaridzika kweCNC yekutemera michina yakati diki, inogona kugadzira matatu-dimensional zvigadzirwa zvakaita sereliefs.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.