YAG laser welding machines require precise cooling to maintain performance and protect the laser source. This article explains their working principle, classifications, and common applications, while highlighting the importance of selecting the right industrial chiller. TEYU laser chillers offer efficient cooling for YAG laser welding systems.

Understanding YAG Laser Welding Machines and Their Chiller Configuration

How YAG Laser Welding Machines Work

YAG laser welding machines generate a 1064nm wavelength laser beam by electrically or lamp-pumping YAG crystals to excite chromium ions. The resulting laser is focused onto the workpiece surface via an optical system, melting the material to form a molten pool. Once cooled, the material solidifies into a weld seam, completing the welding process.

Types and Applications of YAG Laser Welding Machines

YAG laser welders are classified by laser source, pulse mode, and application:

1) By Laser Type: Lamp-pumped YAG lasers offer lower cost and are suitable for general welding applications. Diode-pumped YAG lasers* provide higher efficiency and longer service life, ideal for precision welding.

2) By Pulse Mode: Q-switched pulsed YAG lasers deliver high precision, suitable for micro-welds and specialty materials. Standard pulsed YAG lasers offer broader versatility and cost-effectiveness.

3) By Application Field:

* Automotive manufacturing: Welding of body frames and engine components.

* Electronics manufacturing: Welding of chip leads and circuit traces.

* Hardware industry: Joining of metal fittings for doors, windows, and furniture.

* Jewelry industry: Precision welding of precious metals and gemstones.

Importance of Chiller Configuration for YAG Laser Welders

YAG laser welding machines generate substantial heat during operation. Without effective heat dissipation, laser temperature can rise, leading to power instability, reduced welding quality, or even equipment damage. Therefore, a reliable water chiller is essential for maintaining optimal operating temperature and ensuring consistent welding performance.

Key Factors in Choosing a Laser Chiller

To ensure optimal performance and reliability, consider the following when selecting a laser chiller for YAG laser welders:

1) Cooling Capacity: Match the chiller's cooling power to the laser's output to remove heat efficiently and quickly.

2) Temperature Control Precision: High-precision, intelligent control systems help maintain stable temperatures, minimizing welding defects caused by thermal fluctuations.

3) Safety and Alarm Features: Integrated protections, such as flow, over-temperature, and overcurrent alarms, safeguard the equipment.

4) Energy Efficiency and Environmental Compliance: Choose energy-saving chillers that use eco-friendly refrigerants to reduce operational costs and support sustainability goals.

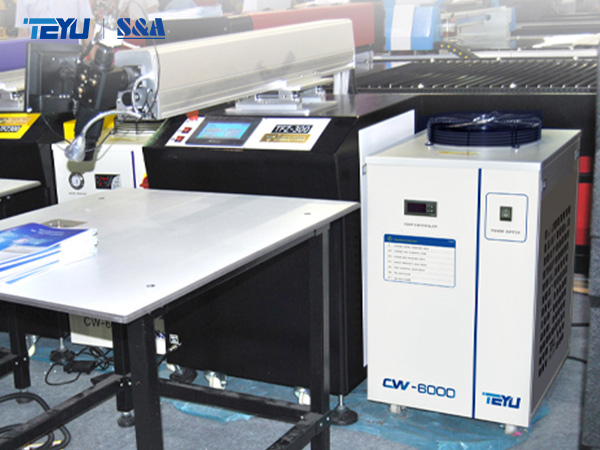

Why Choose TEYU Chillers for YAG Laser Welding Machines

TEYU industrial chillers are engineered to meet the demanding cooling needs of YAG laser welding systems. They offer:

1) Efficient Cooling Performance: Fast and stable heat removal to prevent thermal overload.

2) Precise Temperature Control: Ensures optimal laser performance throughout the welding process.

3) Comprehensive Safety Features: Multiple alarm functions for fault-free operation.

4) Eco-Friendly Design: Low energy consumption and refrigerants compliant with green standards.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.