Heater

Filter

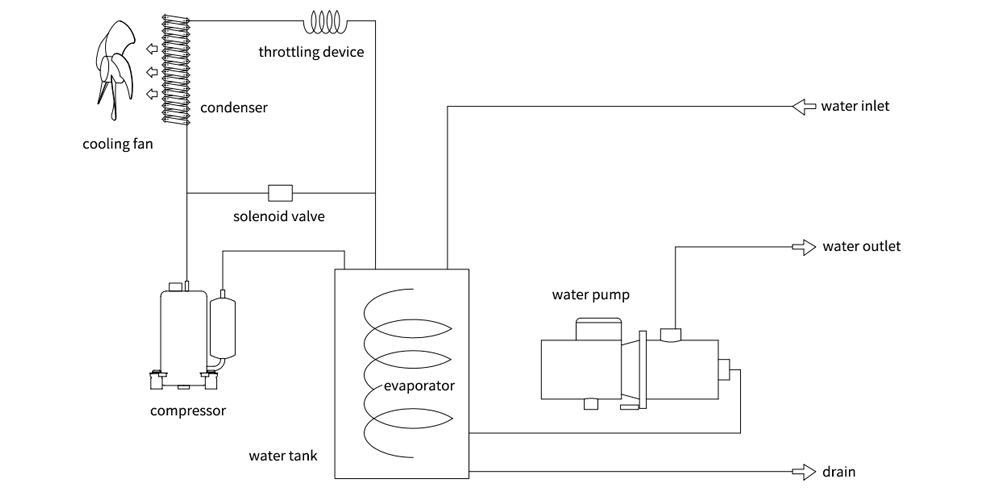

Water chiller machine CW-6300 is essential to keep your 400W CNC CO2 laser cutting machine running strong. It is a stand-alone chiller and doesn’t require additional device to function. CW-6300 air cooled chiller unit is constructed using high quality components: high performance finned coil condenser, high efficiency fixed-speed compressor and hermetic injection molding evaporator. The unique evaporator-in-tank configuration has been specifically designed for process cooling applications. It allows high water flow rates with low pressure drops and ensures reliable operation even in demanding applications. Designed with MODBUS RS-485 communication function, this water cooler allows remote controls including monitoring the working status of the chiller and modifying the parameters of the chiller.

Model: CW-6300

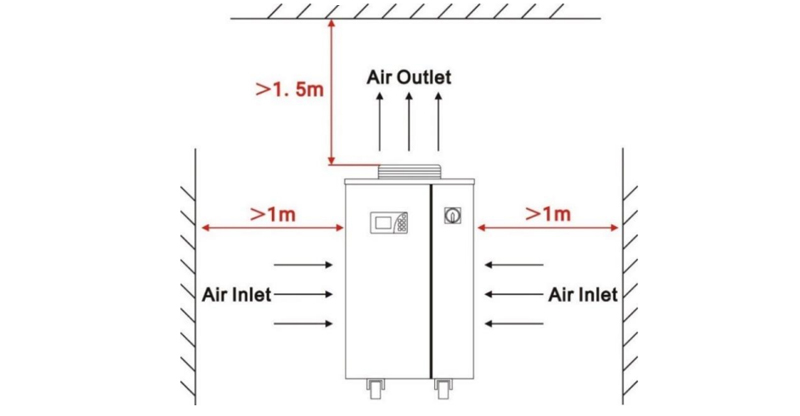

Machine Size: 83X65X117cm (L X W X H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CW-6300AN | CW-6300BN | CW-6300EN |

| Voltage | AC 1P 220-240V | AC 1P 220-240V | AC 3P 380V |

| Frequency | 50Hz | 60Hz | 50Hz |

| Current | 3.4~26.3A | 3.9~29.3A | 1.2~12.6A |

Max. power consumption | 5.24kW | 5.44kW | 5.52kW |

| Compressor power | 2.64kW | 2.71kW | 2.65kW |

| 3.59HP | 4.28HP | 3.6HP | |

| Nominal cooling capacity | 30708Btu/h | ||

| 9kW | |||

| 7738Kcal/h | |||

| Refrigerant | R-410a | ||

| Precision | ±1℃ | ||

| Reducer | Capillary | ||

| Pump power | 0.55kW | 0.75kW | |

| Tank capacity | 40L | ||

| Inlet and outlet | Rp1" | ||

Max. pump pressure | 4.4bar | 5.3bar | 5.4bar |

Max. pump flow | 75L/min | ||

| N.W | 113Kg | 123Kg | 121Kg |

| G.W | 140Kg | 150Kg | 145Kg |

| Dimension | 83X65X117cm (L X W X H) | ||

| Package dimension | 95X77X135cm (L X W X H) | ||

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Cooling Capacity: 9000W

* Active cooling

* Temperature stability: ±1°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410a

* Intelligent temperature controller

* Multiple alarm functions

* Ready for immediate use

* Easy maintenance and mobility

* RS-485 Modbus communication function

* Available in 220V or 380V

Intelligent temperature controller

The temperature controller offers high precision temperature control of ±1°C and two user-adjustable temperature control modes - constant temperature mode and intelligent control mode.

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.