SGIA is the largest and the most authoritative trade show on silk printing, digital printing and imaging technology in North America. It is also one of the three biggest silk printing shows in the world. SGIA gathers the professionals from industrial, graphic, garment, textile, electronics, packaing and commercial printing communities every year and it is held in September or October every year.

For some printing machines like roll-to-roll small format printing machines, silk printing machines, UV LED digital printing machines and UV flatbed printing machines are equipped with UV LED as the light source. As is known to all, the overheating problem will affect the normal working of the UV LED or even lead to the total breakdown of the UV LED. Therefore, it is very necessary to equip the UV LED printing device with effective water chiller units. According to our experience, we provide the model selections guideline of choosing appropriate water chiller units for the UV LED printing device.

For cooling 300W-600W UV LED light source, please select S&A Teyu water chiller unit CW-5000;

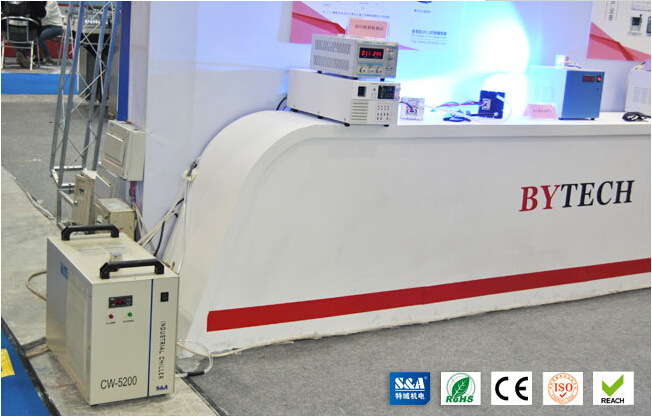

For cooling 1KW-1.4KW UV LED light source, please select S&A Teyu water chiller unit CW-5200;

For cooling 1.6KW-2.5KW UV LED light source, please select S&A Teyu water chiller unit CW-6000;

For cooling 2.5KW-3.6KW UV LED light source, please select S&A Teyu water chiller unit CW-6100;

For cooling 3.6KW-5KW UV LED light source, please select S&A Teyu water chiller unit CW-6200;

For cooling 5KW-9KW UV LED light source, please select S&A Teyu water chiller unit CW-6300;

For cooling 9KW-11KW UV LED light source, please select S&A Teyu water chiller unit CW-7500.