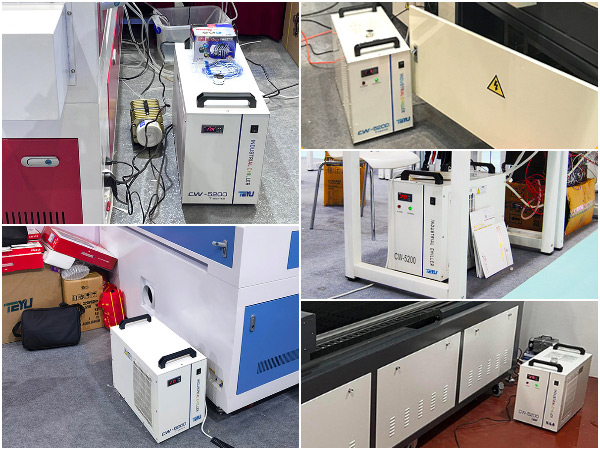

Using a high-quality industrial water chiller is essential for maintaining efficiency and longevity of high-frequency induction heaters. Models such as the TEYU CW-5000 and CW-5200 provide optimal cooling solutions with stable performance, making them ideal choices for small to medium induction heating applications.

Why Induction Heaters Need Industrial Chillers for Stable and Efficient Operation

Understanding Induction Heaters and Their Cooling Needs

High-frequency induction heaters are widely used in industrial applications such as metal heating, hardening, brazing, and welding. These devices use electromagnetic induction to generate heat within the metal workpiece, enabling rapid and precise temperature control. However, induction heating systems produce significant heat in their internal components, including the induction coil and power electronics, requiring an efficient cooling solution to maintain optimal performance and prevent overheating.

Why Induction Heaters Require an Industrial Chiller

Induction heaters operate at high power levels, leading to heat buildup in critical components. Without proper cooling, excessive heat can degrade efficiency, shorten equipment lifespan, and even cause operational failures. An industrial water chiller provides a closed-loop cooling system that circulates temperature-controlled water to dissipate heat, ensuring the induction heater remains within safe operating limits.

Selecting the Right Industrial Chiller for Induction Heaters

Choosing the correct industrial chiller depends on the induction heater's power capacity and cooling requirements. Taking the Vevor HT-15A induction heater as an example, it requires a reliable cooling system to handle the heat generated during prolonged operation. Key factors to consider when selecting an industrial chiller include:

Cooling Capacity – The chiller must have sufficient cooling power to maintain a stable water temperature, typically around 25°C. Chiller models like the TEYU CW-5000 or CW-5200 industrial chillers offer efficient cooling for small to medium induction heaters.

Water Flow Rate – A minimum flow rate of 6L/min or higher ensures effective heat dissipation.

Temperature Control – An industrial chiller with adjustable temperature settings allows precise control for different heating applications.

Closed-loop System – Prevents contamination and scale buildup, ensuring long-term reliability.

Compact Design – An industrial-grade but space-saving chiller is ideal for workshop environments.

Benefits of Using an Industrial Chiller for Induction Heating

Prevents Overheating – Maintains stable operation and protects electronic components.

Enhances Efficiency – Keeps the heater running at peak performance for extended use.

Extends Equipment Lifespan – Reduces wear and tear, minimizing maintenance needs.

Ensures Process Stability – Delivers consistent heating results with precise temperature regulation.

In conclusion, for high-frequency induction heaters, using a high-quality industrial water chiller is essential for maintaining efficiency and longevity. Models such as TEYU CW-5000 and CW-5200 chiller provide optimal cooling solutions with stable performance, making them ideal choices for induction heating applications. Feel free to contact us now to get your exclusive cooling solution.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.