Why is your industrial chiller not cooling down? How do you fix cooling problems? This article will make you to understand the causes of abnormal cooling of industrial chillers and the corresponding solutions, helping industrial chiller to cool effectively and stably, extend its service life and create more value for your industrial processing.

Why Is Industrial Chiller Not Cooling Down? How Do You Fix Cooling Problems?

When using an industrial chiller, if you encounter intermittent ultrahigh water temperatures or prolonged operation without a decrease in temperature, the issue may be caused by the following reasons:

1.Mismatch between Chiller Power and Cooling Capacity with Equipment to be Cooled

When selecting an industrial chiller, it's essential to match it with the power and cooling requirements of the equipment. Only by choosing the right industrial chiller can you effectively provide cooling for the equipment, ensuring its proper operation and extending its lifespan. TEYU industrial water chillers can be applied in over 100 manufacturing and processing industries, with the capability to cool up to 60kW fiber laser equipment. TEYU Chiller sales engineers can provide professional and practical matching solutions based on your specific needs. If you have any questions regarding water chiller selection, please contact us at sales@teyuchiller.com.

2.External Factors

During the summer when temperatures exceed 40℃, industrial chillers struggle to dissipate heat, resulting in poor cooling system performance. It is advisable to operate the industrial chiller in a well-ventilated environment at temperatures below 40℃. The ideal operating temperature range for industrial water chillers is between 20℃ and 30℃.

Additionally, in the summer, there is a high demand for electricity, leading to fluctuations in grid voltage based on actual power consumption. Both excessively high and low voltage can affect equipment operation. It is recommended to use the industrial chiller under stable voltage conditions and, if necessary, install a voltage stabilizer.

3.Check the Industrial Chiller's Internal Systems

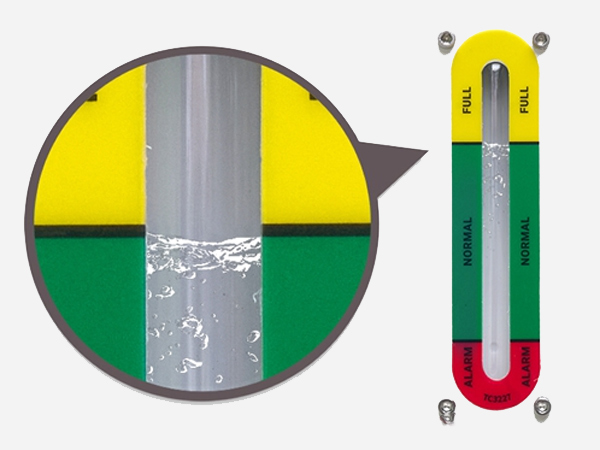

Firstly, check the industrial chiller's water level, and it is recommended to fill it to the highest level of the green zone on the water level gauge. During chiller unit installation, ensure that there is no air inside the unit, water pump, or pipelines. Even a small amount of air can affect the normal operation of the industrial chiller.

Secondly, insufficient refrigerant can affect the industrial chiller's cooling efficiency. You can contact our after-sales service team at service@teyuchiller.com to locate any leaks, perform welding repairs, and recharge the refrigerant.

Finally, pay attention to the operating efficiency of the compressor. Prolonged operation of the compressor can lead to issues like aging of moving parts, increased clearances, or inadequate sealing, resulting in reduced actual exhaust volume and a decrease in overall cooling capacity. Furthermore, issues with the compressor, such as reduced capacitor capacity or abnormalities, can also cause cooling problems, necessitating compressor maintenance or replacement.

Professional note: Tasks involving refrigerant leak detection, refrigerant recharge, and compressor maintenance require specialized technical expertise, so it is advisable to seek assistance from professionals.

4.Enhance Maintenance for Efficient Cooling

Regularly clean the dust filters and condenser dust, and replace the circulating water to prevent poor heat dissipation or pipe blockages, which can lead to inefficient heat removal and reduced cooling efficiency.

To ensure the proper operation of your industrial water chiller during everyday use, also consider the following:

(1)Pay attention to changes in ambient temperature and humidity, and adjust the equipment's operating status as needed based on actual conditions.

(2)Periodically check the electrical connections for good contact and monitor power supply stability.

(3)Ensure that the water chiller has sufficient clearance in its operating environment for effective heat dissipation and ventilation.

(4)For a water chiller that has been unused for an extended period, conduct a comprehensive inspection before startup to ensure safety and reliability.

Proper usage and maintenance of the industrial chiller can effectively and stably provide cooling, extend the industrial chiller's lifespan, and create greater value for industrial processing applications.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.