Ngokuqwalasela ngokubanzi iipropati eziphathekayo, iiparamitha ze-laser, kunye nezicwangciso zenkqubo, eli nqaku libonelela ngezisombululo ezisebenzayo zokucocwa kwe-laser kwiindawo ezinomngcipheko ophezulu. Ezi ndlela zijolise ekuqinisekiseni ukucocwa ngokufanelekileyo ngelixa unciphisa amandla omonakalo wezinto eziphathekayo-ukwenza ukucocwa kwe-laser kukhuselekile kwaye kunokwethenjelwa ngakumbi kwizicelo ezibucayi kunye neziyinkimbinkimbi.

Izisombululo zokuCoca iLaser: Ukujongana nemingeni kwi-High-Risk Material Processing

Ukucocwa kweLaser kuye kwavela njengobuchwephesha obusebenza ngokugqibeleleyo, obungadibanisi nokuchaneka kokususa. Nangona kunjalo, xa ujongana nemathiriyeli ebuthathaka, kubalulekile ukulungelelanisa ukusebenza kokucoca kunye nokhuseleko lwemathiriyeli. Eli nqaku libonisa indlela ecwangcisiweyo yokujongana neemeko ezinomngcipheko ophezulu ngokuhlalutya iimpawu zezinto eziphathekayo, iiparamitha ze-laser, kunye noyilo lwenkqubo.

IiNdlela zoLonakaliso kunye nemilinganiselo yokuLawula kwiZixhobo ezikuMngcipheko oPhezulu wokuCoca iLaser

1. Izinto ezingevayo ngobushushu

I-Mechanism Mechanism: Izinto eziphathekayo ezinamaqondo aphantsi okuncibilika okanye ukungahambi kakuhle kwe-thermal-ezifana neeplastiki okanye i-rubber-zilungele ukuthambisa, i-carbonization, okanye i-deformation ngenxa yokwakhiwa kobushushu ngexesha lokucoca i-laser.

Izisombululo: (1) Kwimathiriyeli efana neeplastiki kunye nerabha: Sebenzisa i-laser ye-pulsed yamandla aphantsi edityaniswe negesi engasebenziyo (umz., initrogen) yokupholisa. I-pulse spacing efanelekileyo ivumela ukutshatyalaliswa kobushushu obusebenzayo, ngelixa igesi ye-inert inceda ukwahlula i-oksijini, ukunciphisa i-oxidation. (2) Kwimathiriyeli enemingxuma efana neplanga okanye i-ceramic: Faka amandla aphantsi, iilaser ezimfutshane ezineskeni ezininzi. Isakhiwo sangaphakathi se-porous sinceda ukusabalalisa amandla e-laser ngokubonakalisa ngokuphindaphindiweyo, ukunciphisa umngcipheko wokushisa kwendawo.

2. Izinto eziManyeneyo eziDityanisiweyo

Umonakalo weMechanism: Amazinga ahlukeneyo okufunxa amandla phakathi kwamaleya anokubangela umonakalo ongekho ngabom kwi-substrate okanye ikhokelele kwi-coating detachment.

Izisombululo: (1) Ngezinyithi ezipeyintiweyo okanye izinto ezidityanisiweyo: Lungisa i-engile yesiganeko selaser ukuguqula indlela yokubonakalisa. Oku kwandisa ulwahlulo lwe-interface ngelixa kunciphisa ukungena kwamandla kwi-substrate. (2) Kwii-substrates ezigqunyiweyo (umz., i-chrome-plated molds): Sebenzisa iilaser ze-ultraviolet (UV) ezinobude obukhethekileyo bobude. I-laser ye-UV inokukhetha ngokukhetha ukuvala i-coating ngaphandle kokuhambisa ubushushu obugqithisileyo, ukunciphisa umonakalo kwizinto eziphantsi.

3. Izinto ezinobunzima obuphezulu kunye ne-Brittle

I-Mechanism Mechanism: Izinto ezifana neglasi okanye i-silicon eyodwa-crystal inokuphuhlisa i-microcracks ngenxa yokungafani kokwandiswa kwe-thermal okanye utshintsho olukhawulezayo kwi-crystal structure.

Izisombululo: (1) Kwimathiriyeli efana neglasi okanye isilicon ye-monocrystalline: Sebenzisa i-ultra-short pulse lasers (umzekelo, iilaser ze-femtosecond). Ukufunxa kwabo okungahambelaniyo kwenza ukuba ukuhanjiswa kwamandla ngaphambi kokuba i-lattice vibrations yenzeke, ukunciphisa umngcipheko we-microcracks. (2) Kwi-carbon fiber composites: Sebenzisa ubuchule bokubumba i-beam, njengeeprofayili ze-annular beam, ukuqinisekisa ukuhanjiswa kwamandla afanayo kunye nokunciphisa uxinzelelo lwexinzelelo kwi-interfaces ye-resin-fiber, enceda ukuthintela ukuqhekeka.

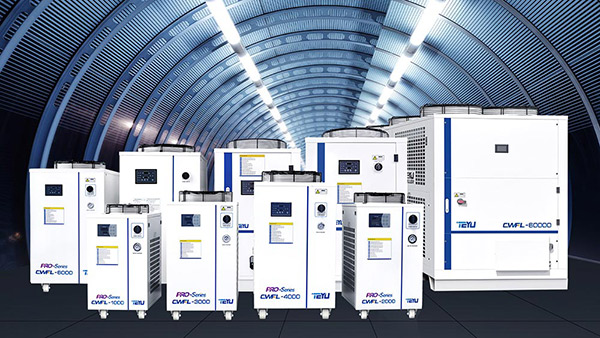

I-Industrial Chillers : I-Ally ebaluleke kakhulu ekuKhuselweni kwezinto eziphathekayo ngexesha lokucoca i-Laser

I-industrial chillers idlala indima ephambili ekunciphiseni umngcipheko womonakalo wezinto eziphathekayo obangelwa kuqokelelwa kobushushu ngexesha lokucoca nge-laser. Ulawulo lwabo lokushisa oluchanekileyo luqinisekisa amandla azinzileyo e-laser kunye nomgangatho we-beam phantsi kweemeko ezahlukeneyo zokusebenza. Ukutshatyalaliswa kokushisa okusebenzayo kuthintela ukugqithiswa kwezinto ezithintekayo ukushisa, ukuphepha ukuthambisa, i-carbonization, okanye i-deformation.

Ukongeza ekukhuseleni izixhobo, ii-chillers zikwakhusela imithombo ye-laser kunye namalungu okukhanya, ukwandisa ubomi besixhobo. Ixhotyiswe ngeempawu zokhuseleko ezakhelwe ngaphakathi, i-industrial chillers ibonelela ngezilumkiso zakwangoko kunye nokhuseleko oluzenzekelayo kwimeko yokungasebenzi kakuhle, ukunciphisa umngcipheko wokungaphumeleli kwezixhobo okanye izehlo zokhuseleko.

Ukuqukumbela

Ngokuqwalasela ngokubanzi iipropati eziphathekayo, iiparamitha ze-laser, kunye nezicwangciso zenkqubo, eli nqaku libonelela ngezisombululo ezisebenzayo zokucocwa kwe-laser kwiindawo ezinomngcipheko ophezulu. Ezi ndlela zijolise ekuqinisekiseni ukucocwa ngokufanelekileyo ngelixa unciphisa amandla omonakalo wezinto eziphathekayo-ukwenza ukucocwa kwe-laser kukhuselekile kwaye kunokwethenjelwa ngakumbi kwizicelo ezibucayi kunye neziyinkimbinkimbi.

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.