Heater

Filter

TEYU High Power Fiber Laser Cooling System CWFL-40000 is a high-performance laser chiller specially designed for cooling 40kW high power fiber laser cutting machine, which offers advanced features while also making cooling easier and more efficient. With dual cooling loops, this recirculating water chiller has enough capacity to cool the fiber laser and the optics independently and simultaneously. The refrigerant circuit system adopts solenoid valve bypass technology to avoid the compressor's frequent start/stop to prolong its service life. All of the components are carefully selected to ensure reliable operation.

Fiber Laser Chiller CWFL-40000 provides an RS-485 interface for communication with the high power fiber lasers. A smart temperature controller is installed with advanced software to optimize the water chiller's performance. A variety of built-in alarm devices to further protect the chiller and laser equipment. In compliance with CE, RoHS and REACH approval. Customization is available.

Model: CWFL-40000

Machine Size: 279 × 96 × 150 cm (L × W × H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CWFL-40000ETTY | CWFL-40000FTTY |

| Voltage | AC 3P 380V | AC 3P 380V |

| Frequency | 50Hz | 60Hz |

| Current | 10.6~85.9A | 15.8~85.9A |

| Max. power consumption | 45.6kW | 49.6kW |

| Heater power | 1.8kW+12kW | |

| Precision | ±1.5℃ | |

| Reducer | Capillary | |

| Pump power | 3.5kW+3.5kW | 3kW+3kW |

| Tank capacity | 340L | |

| Inlet and outlet | Rp1/2"+Rp2" | Rp1/2"+Rp2" |

| Max. pump pressure | 8.5 bar | 8.1 bar |

| Rated flow | 10L/min+>400L/min | |

| N.W. | 694kg | 714kg |

| G.W. | 900kg | 920kg |

| Dimension | 279 × 96 × 150 cm (L × W × H) | |

| Package dimension | 287 × 120 × 175 cm (L × W × H) | |

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Dual cooling circuit

* Active cooling

* Temperature stability: ±1.5°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-32 / R-410A

* Intelligent digital control panel

* Integrated alarm functions

* Back mounted fill port and easy-to-read water level check

* RS-485 Modbus communication function

* High reliability, energy efficiency and durability

* Available in 380V

Heater

Filter

Dual temperature control

The intelligent control panel offers two independent temperature control systems. One is for controlling the temperature of the fiber laser and the other is for controlling the optics.

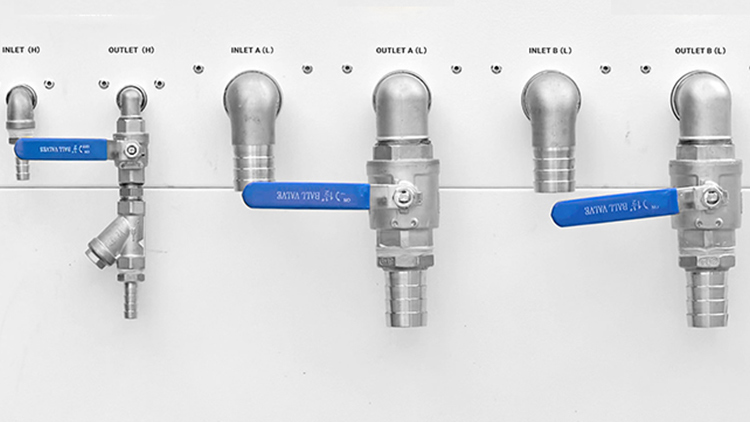

Dual water inlet and water outlet

Water inlets and water outlets are made from stainless steel to prevent potential corrosion or water leakage.

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.