![UV laser small chiller units UV laser small chiller units]()

UV laser features short wavelength, short pulse width, high speed and high peak value. It has become one of the most trending industrial lasers in the current laser market. As UV laser technology develops, its application becomes wider and wider. Nowadays, the commonly seen materials that UV laser can perform quality marking on include plastic, glass, ceramics and metals.

UV laser marking on 3C product plastic

The advent of 3C products is the result of fast development of the electronics industry. To leave a permanent marking on the plastic surface of the electronics, many enterprises introduced the UV laser marking machine. When the UV laser marking machine is working, the working temperature is pretty low with fast speed and enables remote control via the computer to achieve high precision marking. It won't cause distortion on the plastic materials, for it is non-contact.

UV laser marking on metal

Many of you may know that most of the parts of PCB consists of precious metals, including gold, silver and copper. For these tiny parts, manufacturers would add their unique marking on the them for better differentiation. Traditional printing technique is hard to achieve precision marking. But with UV laser whose pulse width is only 15nm@30KHz, precision marking can be easily achieved.

UV laser marking on glass

Glass is a commonly seen in the our daily life. We can often see some beautiful patterns on the glass. They don't have any color, but they are very beautiful. And those patterns are made by using UV laser marking machine. UV laser marking machine is much faster than manual marking and is more efficient with smoother marking surface.

UV laser machine can also be applied to FPC/PCB cutting, profile cutting, drilling and mobile phone shell cutting and produce clear characters and patterns.

Currently, the most mature Ultraviolet laser technology is around 3-10W and is commonly used in industrial level laser micromachining. It can be used to cut wafer, ceramics, thin film and so on. It is believed that UV laser technology will be heading towards higher efficiency, higher power and higher precision.

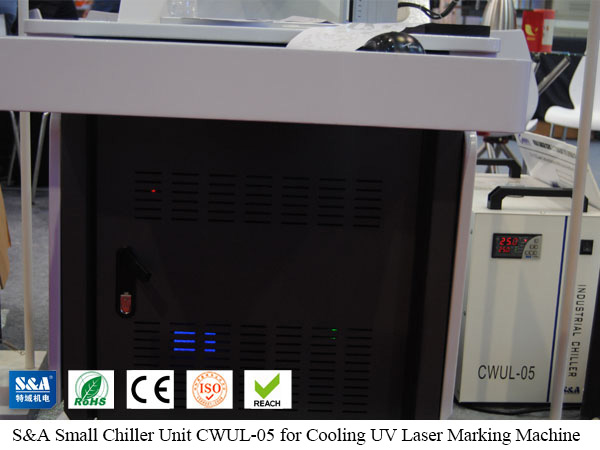

For cooling UV laser machine, it is better to find a reliable laser cooling solution provider. S&A Teyu is such a supplier. It has 19 years of experience and offers CWUL series UV laser small chiller unit which is applicable to cool 3W-5W Ultraviolet laser. This series of portable chiller unit features ±0.2℃ stability and properly designed pipeline, which is the perfect cooling solution for the users. Find out more information at https://www.teyuchiller.com/ultrafast-laser-uv-laser-chiller_c3

![UV laser small chiller units UV laser small chiller units]()