Heater

Filter

US standard plug / EN standard plug

TEYU water chiller CW-6200 is well-suited for cooling CNC grinding machine spindle in need of proper thermal management. Rotating at high speed, the spindle tends to generate lots of heat, which will reduce the spindle machining capacity, the worst case scenario is leading to the whole CNC grinding machine failure, which makes CNC spindle chiller CW-6200 quite necessary. With a cooling capacity of up to 5100W and temperature stability of ±0.5°C, CW-6200 chiller is proven to be particularly useful in maintaining consistent temperature for the spindle of CNC grinding machine.

Industrial chiller CW-6200 features a digital water temperature controller that offers intelligent & constant temperature control modes easy to switch from one another under different requirements. Four heavy-duty caster wheels to ensure easy mobility. And it's available for adding mixtures of water and an anti-rusting agent or anti-freezer up to 30%.

Model: CW-6200

Machine Size: 66 × 48 × 90cm (L × W × H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CW-6200AITY | CW-6200BITY | CW-6200ANTY | CW-6200BNTY |

| Voltage | AC 1P 220-240V | AC 1P 220-240V | AC 1P 220-240V | AC 1P 220-240V |

| Frequency | 50Hz | 60Hz | 50Hz | 60Hz |

| Current | 0.4~12A | 0.4~11.2A | 2.3~14.1A | 2.1~10.1A |

|

Max. power consumption |

1.97kW | 1.97kW | 2.25kW | 1.88kW |

| Compressor power | 1.75kW | 1.7kW | 1.75kW | 1.62kW |

| 2.38HP | 2.27HP | 2.38HP | 2.17HP | |

| Nominal cooling capacity | 17401Btu/h | |||

| 5.1kW | ||||

| 4384Kcal/h | ||||

| Pump power | 0.09kW | 0.37kW | ||

|

Max. pump pressure |

2.5 bar | 2.7 bar | ||

|

Max. pump flow |

15L/min | 75L/min | ||

| Refrigerant | R-410A/R-32 | |||

| Precision | ±0.5℃ | |||

| Reducer | Capillary | |||

| Tank capacity | 22L | |||

| Inlet and outlet | Rp1/2" | |||

| N.W. | 50kg | 52kg | 60kg | 62kg |

| G.W. | 61kg | 63kg | 71kg | 73kg |

| Dimension | 66 × 48 × 90cm (L × W × H) | |||

| Package dimension | 73 × 57 × 105cm (L × W × H) | |||

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Cooling Capacity: 5100W

* Active cooling

* Temperature stability: ±0.5°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410A/R-32

* User-friendly temperature controller

* Integrated alarm functions

* Back mounted water fill port and easy-to-read water level check

* High reliability, energy efficiency and durability

* Simple setup and operation

Heater

Filter

US standard plug / EN standard plug

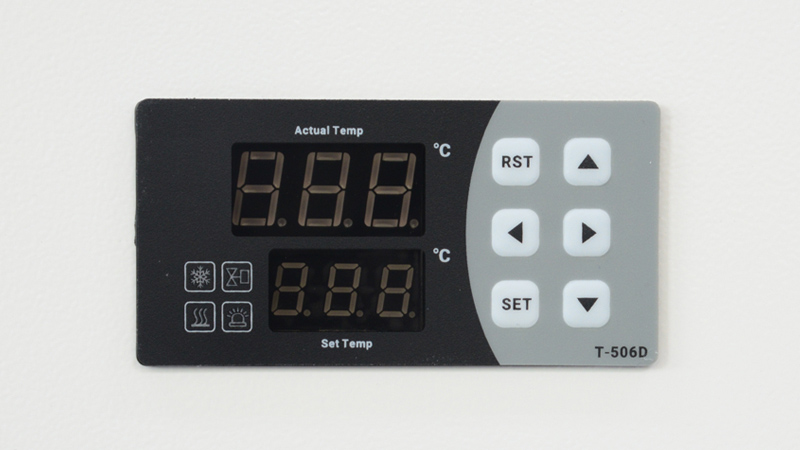

Intelligent temperature controller

The temperature controller offers high precision temperature control of ±0.5°C and two user-adjustable temperature control modes - constant temperature mode and intelligent control mode.

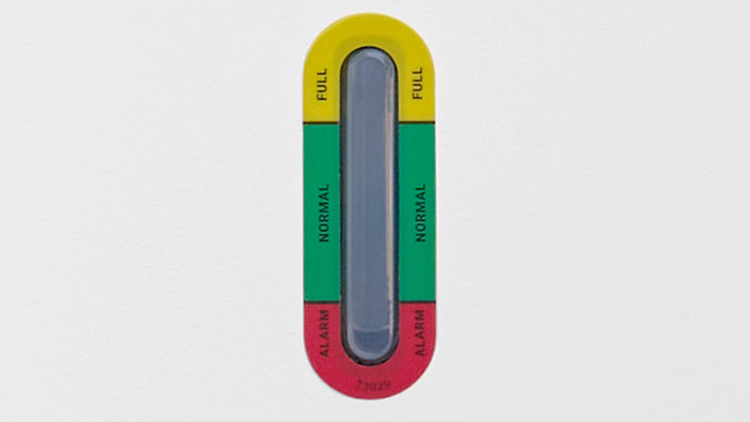

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.